CORE_COMPETENCE

Product_Leaders

index_more

index_more_content

info_item01

info_item_content01

info_item02

info_item_content02

info_item03

info_item_content03

info_item04

info_item_content04

NEWS

NEWS

What industries do capacitor cabinet application scenarios include?

What Industries Do Capacitor Cabinet Application Scenarios Include?

I. Introduction

In the realm of electrical systems, capacitor cabinets play a pivotal role in enhancing efficiency and reliability. These specialized enclosures house capacitors and associated components that are essential for power factor correction, voltage regulation, and harmonic filtering. As industries strive for energy efficiency and sustainability, the importance of capacitor cabinets has surged, making them integral to various sectors. This article aims to explore the diverse industries that utilize capacitor cabinets, their applications, benefits, and emerging trends.

II. Understanding Capacitor Cabinets

A. Components of a Capacitor Cabinet

A capacitor cabinet typically consists of several key components:

1. **Capacitors**: These are the primary elements that store electrical energy and release it when needed, helping to improve power factor and stabilize voltage levels.

2. **Control Systems**: These systems monitor and manage the operation of the capacitors, ensuring they function optimally based on the electrical load.

3. **Protection Devices**: These include fuses, circuit breakers, and surge protectors that safeguard the system from electrical faults and overloads.

B. Functionality of Capacitor Cabinets

Capacitor cabinets serve several critical functions:

1. **Power Factor Correction**: By compensating for reactive power, capacitor cabinets help improve the power factor of electrical systems, reducing energy losses and lowering utility bills.

2. **Voltage Regulation**: They stabilize voltage levels, ensuring that electrical equipment operates efficiently and reducing the risk of damage due to voltage fluctuations.

3. **Harmonic Filtering**: Capacitor cabinets can mitigate harmonics generated by non-linear loads, improving overall power quality and reducing stress on electrical systems.

III. Key Industries Utilizing Capacitor Cabinets

A. Manufacturing Industry

In the manufacturing sector, capacitor cabinets are essential for motor control and energy efficiency improvements. Motors are significant consumers of reactive power, and capacitor cabinets help reduce this demand, leading to lower energy costs. By improving power factor, manufacturers can also enhance the performance and lifespan of their machinery, resulting in increased productivity.

B. Utilities and Power Generation

Utilities and power generation companies rely on capacitor cabinets to maintain grid stability and reliability. These systems help manage reactive power flow, ensuring that the grid operates efficiently. Additionally, as renewable energy sources like wind and solar become more prevalent, capacitor cabinets facilitate their integration into the grid, helping to balance supply and demand.

C. Commercial Buildings

In commercial buildings, capacitor cabinets optimize HVAC systems and improve lighting efficiency. By correcting power factor and stabilizing voltage, these cabinets ensure that heating, ventilation, and air conditioning systems operate effectively, leading to significant energy savings. Furthermore, efficient lighting systems contribute to lower operational costs and enhanced occupant comfort.

D. Transportation and Infrastructure

Capacitor cabinets play a crucial role in the electrification of transport systems, including railways and airports. They provide reliable power supply and improve the efficiency of electric trains and airport ground support equipment. By ensuring stable voltage and power quality, capacitor cabinets enhance the performance and reliability of transportation infrastructure.

E. Telecommunications

In the telecommunications industry, power quality management is vital for maintaining service reliability. Capacitor cabinets help mitigate voltage sags and harmonics, ensuring that communication systems operate smoothly. Additionally, they provide backup power solutions, safeguarding critical infrastructure against outages.

F. Data Centers

Data centers are significant consumers of energy, and capacitor cabinets help manage this consumption effectively. By improving power factor and supporting cooling systems, these cabinets contribute to energy efficiency and operational reliability. As data centers continue to grow, the role of capacitor cabinets in energy management becomes increasingly important.

IV. Emerging Applications and Trends

A. Smart Grids and IoT Integration

The advent of smart grids and the Internet of Things (IoT) is transforming the way capacitor cabinets are utilized. These technologies enable real-time monitoring and control of capacitor systems, optimizing their performance and enhancing grid reliability. As industries adopt smart technologies, the demand for advanced capacitor solutions is expected to rise.

B. Electric Vehicle Charging Stations

With the growing popularity of electric vehicles (EVs), capacitor cabinets are becoming essential for charging infrastructure. They help manage the reactive power demands of charging stations, ensuring efficient operation and minimizing the impact on the grid.

C. Renewable Energy Systems

Capacitor cabinets are increasingly being integrated into renewable energy systems, such as solar and wind power. They help manage the variability of these energy sources, improving grid stability and facilitating their widespread adoption.

1. **Solar Power Integration**: Capacitor cabinets can enhance the performance of solar inverters, improving energy conversion efficiency and power quality.

2. **Wind Energy Applications**: In wind farms, capacitor cabinets help manage reactive power and stabilize voltage, ensuring reliable energy delivery to the grid.

V. Benefits of Using Capacitor Cabinets Across Industries

A. Cost Savings and Return on Investment

One of the most significant advantages of capacitor cabinets is the potential for cost savings. By improving power factor and reducing energy losses, industries can achieve a quick return on investment. Lower utility bills and reduced demand charges contribute to overall financial benefits.

B. Enhanced Equipment Lifespan

By stabilizing voltage and reducing harmonics, capacitor cabinets help extend the lifespan of electrical equipment. This leads to lower maintenance costs and fewer unexpected failures, enhancing operational efficiency.

C. Environmental Impact and Sustainability

Capacitor cabinets contribute to sustainability efforts by improving energy efficiency and reducing carbon footprints. As industries strive to meet environmental regulations and corporate sustainability goals, the adoption of capacitor solutions becomes increasingly important.

D. Compliance with Regulatory Standards

Many industries are subject to regulatory standards regarding power quality and energy efficiency. Capacitor cabinets help organizations comply with these standards, avoiding potential penalties and enhancing their reputation.

VI. Challenges and Considerations

A. Initial Investment and Budget Constraints

While the long-term benefits of capacitor cabinets are clear, the initial investment can be a barrier for some organizations. Budget constraints may limit the ability to implement these solutions, particularly for smaller businesses.

B. Maintenance and Technical Expertise

Capacitor cabinets require regular maintenance and monitoring to ensure optimal performance. Organizations may need to invest in training or hire specialized personnel to manage these systems effectively.

C. Technological Advancements and Upgrades

As technology continues to evolve, industries must stay abreast of advancements in capacitor cabinet solutions. Upgrading to newer, more efficient systems may be necessary to maintain competitiveness and efficiency.

VII. Conclusion

Capacitor cabinets are indispensable components in various industries, providing essential functions that enhance energy efficiency, reliability, and sustainability. From manufacturing to telecommunications, the applications of capacitor cabinets are vast and varied. As industries continue to evolve and embrace new technologies, the role of capacitor cabinets will only grow in importance. Organizations are encouraged to consider the benefits of capacitor solutions and invest in these systems to improve their operational efficiency and contribute to a more sustainable future.

VIII. References

- Academic Journals

- Industry Reports

- Manufacturer Guidelines and Specifications

In conclusion, capacitor cabinets are not just a technical necessity; they are a strategic investment for industries aiming to enhance their operational efficiency and sustainability. As we move towards a more energy-conscious future, the role of capacitor cabinets will undoubtedly expand, paving the way for innovative applications and solutions.

2025-02-20

What are the manufacturing processes of the latest fan capacitors?

What are the Manufacturing Processes of the Latest Fan Capacitors?

I. Introduction

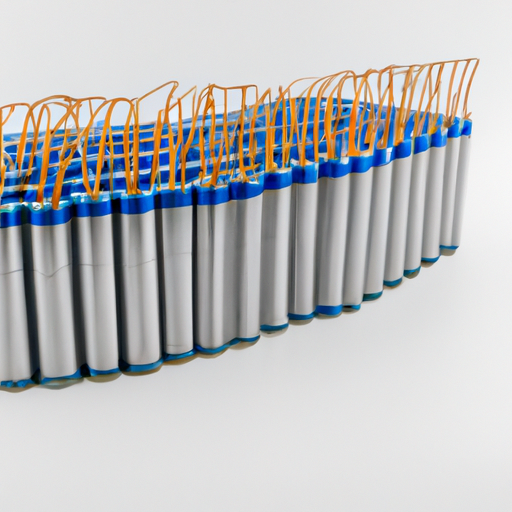

Fan capacitors are essential components in electrical systems, particularly in electric motors used in fans, air conditioners, and various appliances. These capacitors play a crucial role in enhancing motor efficiency, improving energy consumption, and ensuring the smooth operation of devices. As technology advances, the manufacturing processes of fan capacitors have evolved, incorporating new materials and techniques to meet the demands of modern applications. This article aims to provide an in-depth look at the manufacturing processes of the latest fan capacitors, exploring the raw materials used, the steps involved in production, and the innovations shaping the industry.

II. Understanding Fan Capacitors

A. Types of Fan Capacitors

Fan capacitors can be broadly categorized into two types: run capacitors and start capacitors.

1. **Run Capacitors**: These capacitors are used in continuous operation applications, providing a steady voltage to the motor. They help improve the efficiency of the motor by maintaining a consistent phase difference between the current and voltage.

2. **Start Capacitors**: These capacitors are designed for short-term use, providing an initial boost of energy to start the motor. Once the motor reaches a certain speed, the start capacitor is typically disconnected from the circuit.

B. Functionality and Applications

Fan capacitors are integral to the functionality of electric motors. They enhance motor efficiency by improving the power factor, which reduces energy consumption. This is particularly important in applications where motors run continuously, such as in HVAC systems and industrial fans. Recent advancements in fan capacitor technology have led to the development of more compact and efficient designs, further optimizing energy use.

III. Raw Materials Used in Fan Capacitor Manufacturing

The manufacturing of fan capacitors involves a variety of raw materials, each selected for its specific properties.

A. Dielectric Materials

Dielectric materials are crucial for the capacitor's function, as they store electrical energy. Common dielectric materials include:

1. **Polypropylene**: Known for its high dielectric strength and low loss factor, polypropylene is widely used in fan capacitors.

2. **Polyester**: This material offers good thermal stability and is often used in applications requiring moderate capacitance.

3. **Ceramic**: Ceramic capacitors are known for their reliability and stability, making them suitable for high-frequency applications.

B. Conductive Materials

Conductive materials are essential for the capacitor's ability to conduct electricity. The most commonly used conductive materials are:

1. **Aluminum**: Lightweight and cost-effective, aluminum is often used for the capacitor's plates.

2. **Copper**: Known for its excellent conductivity, copper is sometimes used in high-performance capacitors.

C. Insulating Materials

Insulating materials are used to prevent electrical leakage and ensure safety. Common insulating materials include:

1. **Epoxy Resins**: These materials provide excellent insulation and are often used in the encapsulation process.

2. **PVC**: Polyvinyl chloride is used for its durability and resistance to environmental factors.

D. Environmental Considerations in Material Selection

Manufacturers are increasingly considering environmental factors when selecting materials. This includes choosing recyclable materials and minimizing the use of harmful substances to comply with regulations such as RoHS (Restriction of Hazardous Substances).

IV. Manufacturing Processes of Fan Capacitors

The manufacturing of fan capacitors involves several key processes, each critical to ensuring the final product meets quality and performance standards.

A. Design and Engineering

The manufacturing process begins with design and engineering.

1. **Computer-Aided Design (CAD) Tools**: Engineers use CAD software to create detailed designs of the capacitors, optimizing dimensions and materials for performance.

2. **Prototyping and Testing**: Prototypes are created to test the design's functionality and performance. This stage is crucial for identifying any potential issues before mass production.

B. Dielectric Film Production

The dielectric film is a core component of the capacitor.

1. **Film Extrusion Process**: The dielectric material is extruded into thin films, which are then cut to the required dimensions.

2. **Thickness and Quality Control**: The thickness of the film is critical for performance, and quality control measures are implemented to ensure consistency.

C. Capacitor Assembly

The assembly process involves layering and combining the dielectric and conductive materials.

1. **Layering of Dielectric and Conductive Materials**: The dielectric film is layered with conductive materials, creating the capacitor's structure.

2. **Winding and Stacking Techniques**: Depending on the design, the layers may be wound into a cylindrical shape or stacked flat to form the capacitor.

D. Encapsulation and Insulation

Once assembled, the capacitor must be insulated and encapsulated.

1. **Application of Insulating Materials**: Insulating materials are applied to prevent electrical leakage and protect the capacitor from environmental factors.

2. **Methods of Encapsulation**: Various methods, such as potting and molding, are used to encapsulate the capacitor, ensuring durability and reliability.

E. Quality Control and Testing

Quality control is a critical step in the manufacturing process.

1. **Electrical Testing**: Each capacitor undergoes electrical testing to verify capacitance, voltage rating, and other performance metrics.

2. **Mechanical Testing**: Mechanical tests, such as vibration and thermal cycling, ensure the capacitor can withstand operational stresses.

3. **Compliance with Industry Standards**: Manufacturers must ensure their products comply with industry standards, such as UL (Underwriters Laboratories) and IEC (International Electrotechnical Commission) regulations.

V. Innovations in Fan Capacitor Manufacturing

The fan capacitor manufacturing industry is witnessing several innovations that enhance production efficiency and product performance.

A. Automation and Robotics in Production

Automation and robotics are increasingly being integrated into the manufacturing process, improving precision and reducing labor costs. Automated systems can handle repetitive tasks, allowing human workers to focus on more complex operations.

B. Smart Capacitors and IoT Integration

The rise of the Internet of Things (IoT) has led to the development of smart capacitors that can communicate with other devices. These capacitors can monitor performance in real-time, providing data that can be used to optimize energy consumption and maintenance schedules.

C. Sustainable Manufacturing Practices

Sustainability is becoming a priority in manufacturing.

1. **Recycling of Materials**: Manufacturers are exploring ways to recycle materials used in capacitor production, reducing waste and environmental impact.

2. **Energy-Efficient Production Methods**: Implementing energy-efficient practices in manufacturing processes helps reduce the overall carbon footprint.

D. Future Trends in Fan Capacitor Technology

As technology continues to evolve, future trends may include the development of even more efficient materials, enhanced smart capabilities, and further integration of sustainable practices in manufacturing.

VI. Challenges in Fan Capacitor Manufacturing

Despite advancements, the manufacturing of fan capacitors faces several challenges.

A. Supply Chain Issues for Raw Materials

Global supply chain disruptions can impact the availability and cost of raw materials, affecting production timelines and pricing.

B. Meeting Regulatory Requirements

Manufacturers must navigate complex regulatory environments, ensuring compliance with various standards while maintaining product quality.

C. Balancing Cost and Quality

Finding the right balance between cost and quality is a constant challenge. Manufacturers must invest in high-quality materials and processes while keeping production costs competitive.

D. Adapting to Rapid Technological Changes

The fast pace of technological change requires manufacturers to stay ahead of trends and continuously innovate to meet market demands.

VII. Conclusion

Fan capacitors are vital components in modern electrical systems, playing a crucial role in motor efficiency and energy consumption. The manufacturing processes of these capacitors have evolved significantly, incorporating advanced materials and techniques to enhance performance and sustainability. As the industry continues to innovate, the future of fan capacitor technology looks promising, with opportunities for further research and development. Manufacturers must remain agile, adapting to challenges and embracing new technologies to meet the demands of a rapidly changing market.

VIII. References

1. Academic journals and articles on capacitor technology and manufacturing processes.

2. Industry reports and white papers detailing advancements in fan capacitor technology.

3. Manufacturer specifications and guidelines for fan capacitors.

4. Relevant standards and regulations governing capacitor manufacturing and safety.

This comprehensive overview of fan capacitor manufacturing processes highlights the importance of these components in electrical systems and the ongoing innovations shaping their production. As the industry evolves, continued research and development will be essential to meet the growing demands for efficiency and sustainability.

2025-02-19

What are the popular models of capacitor capacitor formulas?

What are the Popular Models of Capacitor and Capacitor Formulas

I. Introduction

Capacitors are fundamental components in electrical and electronic circuits, playing a crucial role in various applications ranging from energy storage to signal processing. A capacitor is a passive electronic component that stores electrical energy in an electric field, created by a pair of conductive plates separated by an insulating material known as a dielectric. Understanding the different models of capacitors and their associated formulas is essential for engineers and technicians who design and analyze circuits. This article will explore the basic concepts of capacitors, popular models, key formulas, and their applications in real-world scenarios.

II. Basic Concepts of Capacitors

A. Definition and Function of Capacitors

Capacitors serve as energy storage devices, allowing for the temporary storage of electrical charge. When a voltage is applied across the capacitor's plates, an electric field develops, causing positive and negative charges to accumulate on opposite plates. This stored energy can be released when needed, making capacitors vital in various applications, including power supply smoothing, timing circuits, and filtering.

B. Key Parameters of Capacitors

1. **Capacitance (C)**: The ability of a capacitor to store charge, measured in Farads (F). It is defined as the ratio of the electric charge (Q) stored on one plate to the voltage (V) across the plates: \( C = \frac{Q}{V} \).

2. **Voltage Rating (V)**: The maximum voltage that can be applied across the capacitor without risking breakdown or failure.

3. **Equivalent Series Resistance (ESR)**: A measure of the resistive losses in a capacitor, which can affect its performance, especially in high-frequency applications.

4. **Leakage Current**: The small amount of current that flows through the dielectric material, even when the capacitor is not in use. This parameter is crucial for applications requiring low power consumption.

C. Types of Capacitors

1. **Electrolytic Capacitors**: Known for their high capacitance values, these capacitors use an electrolyte as one of the plates. They are polarized, meaning they must be connected in the correct direction.

2. **Ceramic Capacitors**: These capacitors are made from ceramic materials and are known for their stability and reliability. They are often used in high-frequency applications.

3. **Film Capacitors**: Made from thin plastic films, these capacitors offer excellent stability and low ESR, making them suitable for audio and RF applications.

4. **Tantalum Capacitors**: Similar to electrolytic capacitors but with a tantalum metal anode, these capacitors provide high capacitance in a small package.

5. **Supercapacitors**: Also known as ultracapacitors, these devices can store large amounts of energy and are used in applications requiring rapid charge and discharge cycles.

III. Popular Models of Capacitors

A. Ideal Capacitor Model

The ideal capacitor model assumes that the capacitor has no resistance, leakage current, or dielectric losses. In this model, the capacitor's behavior is described by the basic capacitance formula \( C = \frac{Q}{V} \). This model is useful for theoretical analysis and circuit simulations, providing a simplified view of capacitor behavior.

B. Non-Ideal Capacitor Models

1. **Series Resistance Model**: This model incorporates the Equivalent Series Resistance (ESR) of the capacitor. ESR represents the resistive losses that occur when current flows through the capacitor. High ESR can lead to power dissipation and heating, affecting the capacitor's performance, especially in high-frequency applications.

2. **Parallel Resistance Model**: This model accounts for leakage current, which flows through the dielectric material. The parallel resistance represents the leakage path, and it is crucial for applications where low leakage is essential, such as in timing circuits.

3. **Frequency-dependent Models**: These models consider the dielectric losses and impedance characteristics of capacitors at different frequencies. As frequency increases, capacitors may exhibit different behaviors due to factors like dielectric absorption and loss tangent.

C. Advanced Capacitor Models

1. **SPICE Models for Simulation**: SPICE (Simulation Program with Integrated Circuit Emphasis) is a widely used tool for simulating electronic circuits. Capacitor models in SPICE can include various parameters such as ESR, ESL (Equivalent Series Inductance), and temperature coefficients, allowing for accurate predictions of circuit behavior.

2. **Behavioral Models for Specific Applications**: In some cases, capacitors may be modeled based on their specific application requirements. For example, in power electronics, capacitors may be modeled to account for their response to rapid voltage changes.

IV. Capacitor Formulas

A. Basic Capacitor Formula

The fundamental formula for capacitance is given by:

\[

C = \frac{Q}{V}

\]

Where:

- \( C \) is the capacitance in Farads,

- \( Q \) is the charge in Coulombs,

- \( V \) is the voltage in Volts.

B. Energy Stored in a Capacitor

The energy (E) stored in a capacitor can be calculated using the formula:

\[

E = \frac{1}{2} C V^2

\]

Where:

- \( E \) is the energy in Joules,

- \( C \) is the capacitance in Farads,

- \( V \) is the voltage in Volts.

C. Capacitors in Series and Parallel

1. **Series Connection**: When capacitors are connected in series, the total capacitance (\( C_{\text{total}} \)) can be calculated using the formula:

\[

\frac{1}{C_{\text{total}}} = \frac{1}{C_1} + \frac{1}{C_2} + \ldots

\]

2. **Parallel Connection**: For capacitors connected in parallel, the total capacitance is simply the sum of the individual capacitances:

\[

C_{\text{total}} = C_1 + C_2 + \ldots

\]

D. Time Constant in RC Circuits

The time constant (\( \tau \)) in an RC (resistor-capacitor) circuit is given by:

\[

\tau = R \times C

\]

Where:

- \( \tau \) is the time constant in seconds,

- \( R \) is the resistance in Ohms,

- \( C \) is the capacitance in Farads.

The time constant indicates how quickly the capacitor charges or discharges, with implications for the circuit's response time.

V. Applications of Capacitor Models and Formulas

Capacitors are used in a wide range of applications, including:

1. **Power Supply Smoothing**: Capacitors help smooth out voltage fluctuations in power supplies, ensuring a stable output.

2. **Timing Circuits**: In timing applications, capacitors work with resistors to create time delays, essential for oscillators and timers.

3. **Signal Coupling and Decoupling**: Capacitors are used to couple AC signals between stages of amplifiers while blocking DC components, and to decouple power supply variations from sensitive circuits.

4. **Energy Storage in Renewable Energy Systems**: Supercapacitors are increasingly used in renewable energy systems for energy storage, providing rapid charge and discharge capabilities.

5. **Filtering Applications in Audio and Radio Frequency Circuits**: Capacitors are integral to filter circuits, allowing certain frequencies to pass while blocking others, crucial in audio processing and RF applications.

VI. Conclusion

Understanding the various models of capacitors and their associated formulas is essential for engineers and technicians working in electrical and electronic fields. From the ideal capacitor model to advanced simulation techniques, each model provides insights into capacitor behavior and performance. As technology continues to evolve, the importance of capacitors in modern circuits will only grow, making it vital to stay informed about the latest trends and developments in capacitor technology.

VII. References

1. "The Art of Electronics" by Paul Horowitz and Winfield Hill.

2. "Capacitors: Technology and Applications" by John W. McGowan.

3. SPICE Simulation Software Documentation.

4. IEEE Journals on Capacitor Technology and Applications.

This comprehensive overview of capacitors, their models, and formulas serves as a valuable resource for anyone looking to deepen their understanding of this essential electronic component.

2025-02-18