What are the Advantages of Capacitor Manufacturers’ Products?

I. Introduction

Capacitors are essential components in the world of electronics, serving as energy storage devices that play a critical role in various applications. They store electrical energy temporarily and release it when needed, making them vital for smoothing out voltage fluctuations, filtering signals, and providing power in electronic circuits. The importance of capacitors cannot be overstated, as they are found in everything from consumer electronics to industrial machinery. This article explores the advantages of products from capacitor manufacturers, highlighting their quality, technological advancements, customization options, cost-effectiveness, and environmental considerations.

II. Types of Capacitors

Capacitors come in various types, each designed for specific applications and performance requirements. Understanding these types is crucial for selecting the right capacitor for a given application.

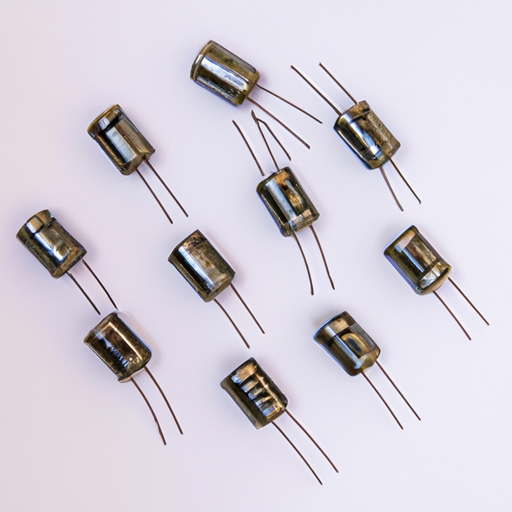

A. Electrolytic Capacitors

Electrolytic capacitors are polarized capacitors that offer high capacitance values in a relatively small package. They are commonly used in power supply circuits and audio applications due to their ability to store large amounts of energy.

B. Ceramic Capacitors

Ceramic capacitors are non-polarized and known for their stability and reliability. They are widely used in high-frequency applications and are favored for their small size and low cost.

C. Film Capacitors

Film capacitors are made from thin plastic films and are known for their excellent performance in terms of stability and low loss. They are often used in audio equipment and power electronics.

D. Tantalum Capacitors

Tantalum capacitors are known for their high capacitance and voltage ratings in a compact size. They are commonly used in applications where space is limited, such as in mobile devices.

E. Supercapacitors

Supercapacitors, or ultracapacitors, offer extremely high capacitance values and are used in applications requiring rapid charge and discharge cycles, such as energy storage systems and regenerative braking in electric vehicles.

F. Comparison of Different Types

Each type of capacitor has its advantages and disadvantages, making it essential for manufacturers to provide a range of options to meet diverse customer needs. Understanding these differences allows engineers and designers to select the most suitable capacitor for their specific applications.

III. Quality and Reliability

A. Manufacturing Standards

One of the primary advantages of products from reputable capacitor manufacturers is adherence to strict manufacturing standards. Many manufacturers hold ISO certifications, which ensure that their products meet international quality standards. This commitment to quality is reflected in their quality control processes, which involve rigorous testing and inspection at various stages of production.

B. Longevity and Durability

Capacitors from established manufacturers are designed to last. They are built to withstand environmental factors such as temperature fluctuations, humidity, and mechanical stress. This durability translates to longer lifespans and reduced need for replacements, making them a reliable choice for critical applications.

C. Failure Rates

Statistical data on failure rates indicates that high-quality capacitors have significantly lower failure rates compared to inferior products. This reliability is crucial in applications where failure can lead to catastrophic consequences, such as in medical devices or aerospace technology.

IV. Technological Advancements

A. Innovations in Capacitor Design

Capacitor manufacturers are continually innovating to improve their products. Miniaturization is a key trend, allowing for smaller capacitors with higher capacitance and voltage ratings. This advancement is particularly important in the consumer electronics market, where space is at a premium.

B. Integration with Other Technologies

The integration of capacitors with other technologies is another area of advancement. Smart capacitors, for example, can monitor their own performance and communicate with other devices, enhancing system efficiency. Additionally, capacitors play a vital role in renewable energy systems, such as solar panels and wind turbines, where they help manage energy storage and distribution.

C. Research and Development Efforts

Leading capacitor manufacturers invest heavily in research and development to explore new materials and technologies. Collaborations with academic institutions and industry partners drive innovation, resulting in products that meet the evolving needs of various industries.

V. Customization and Versatility

A. Tailored Solutions for Specific Applications

One of the significant advantages of working with capacitor manufacturers is the ability to obtain customized solutions. Manufacturers can provide tailored capacitance values and specialized packaging options to meet the unique requirements of different applications.

B. Versatility Across Industries

Capacitors are used across a wide range of industries, including consumer electronics, automotive applications, industrial machinery, and medical devices. This versatility means that manufacturers can cater to diverse markets, providing solutions that enhance performance and efficiency in various settings.

VI. Cost-Effectiveness

A. Economies of Scale

Reputable capacitor manufacturers benefit from economies of scale, allowing them to produce capacitors at lower costs. Mass production techniques and efficient supply chain management contribute to cost reduction strategies that ultimately benefit customers.

B. Long-Term Savings

Investing in high-quality capacitors can lead to long-term savings. Reliable capacitors reduce maintenance costs and improve energy efficiency, resulting in lower operational expenses over time. This cost-effectiveness is particularly appealing to businesses looking to optimize their budgets.

C. Competitive Pricing

The competitive landscape among capacitor manufacturers drives prices down, ensuring that customers receive value for their money. With numerous options available, customers can choose products that meet their performance requirements without exceeding their budgets.

VII. Environmental Considerations

A. Sustainable Manufacturing Practices

Many capacitor manufacturers are committed to sustainable manufacturing practices. This includes the use of eco-friendly materials and waste reduction strategies that minimize their environmental impact. By prioritizing sustainability, manufacturers contribute to a greener future.

B. Recycling and Disposal

End-of-life management is another critical aspect of environmental considerations. Many manufacturers have programs in place for recycling capacitors, ensuring that they are disposed of responsibly. This commitment to recycling helps reduce electronic waste and promotes a circular economy.

VIII. Customer Support and Service

A. Technical Support

Reputable capacitor manufacturers offer robust technical support to their customers. This includes assistance in product selection, troubleshooting, and after-sales service. Having access to knowledgeable support staff can significantly enhance the customer experience and ensure that products are used effectively.

B. Warranty and Return Policies

Manufacturers often provide warranties and return policies that assure customers of product quality. These policies reflect the manufacturers' confidence in their products and contribute to customer satisfaction initiatives.

IX. Conclusion

In summary, the advantages of capacitor manufacturers’ products are numerous and significant. From high-quality and reliable components to innovative designs and customization options, these products play a crucial role in the performance of electronic devices across various industries. As technology continues to evolve, the future of capacitors looks promising, with ongoing advancements that will further enhance their capabilities. Choosing quality manufacturers is essential for ensuring that electronic systems operate efficiently and reliably, ultimately contributing to the success of businesses and the satisfaction of consumers.