What are the Popular Models of Resistor L?

I. Introduction

In the realm of electrical engineering, resistors play a crucial role in controlling the flow of electric current. Among the various types of resistors, Resistor L stands out due to its unique characteristics and applications. This blog post aims to explore the popular models of Resistor L, their functions, advantages, disadvantages, and future trends in resistor technology. By the end of this article, readers will have a comprehensive understanding of Resistor L and its significance in modern electronics.

II. Understanding Resistor L

A. Explanation of Resistor L and its Function

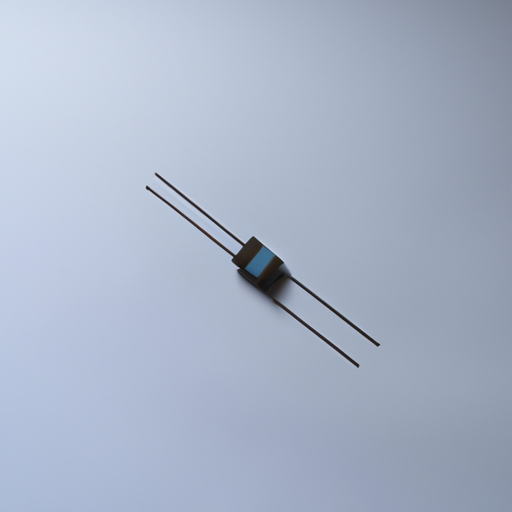

Resistor L refers to a specific category of resistors characterized by their inductive properties. Unlike standard resistors that primarily resist current flow, Resistor L incorporates inductance, which can influence the behavior of alternating current (AC) circuits. This makes Resistor L particularly valuable in applications where phase shift and impedance matching are critical.

B. Types of Resistors and Their Applications

Resistors can be broadly classified into several categories based on their construction and materials. Each type has its unique properties, making them suitable for different applications. The most common types include carbon composition, metal film, wirewound, thick film, thin film, and surface mount resistors. Understanding these types is essential for selecting the right resistor for a specific application.

C. The Role of Resistor L in Circuits

In electronic circuits, Resistor L is often used in conjunction with capacitors and inductors to create filters, oscillators, and other reactive components. Its ability to manage current flow and phase relationships makes it indispensable in audio equipment, radio frequency applications, and power supply circuits.

III. Popular Models of Resistor L

A. Carbon Composition Resistors

1. Description and Characteristics

Carbon composition resistors are made from a mixture of carbon particles and a binding resin. They are known for their high energy absorption capability and are typically used in applications where high pulse loads are expected.

2. Advantages and Disadvantages

**Advantages:**

- High pulse handling capability

- Cost-effective

- Wide availability

**Disadvantages:**

- Poor temperature stability

- Higher noise levels compared to other types

3. Common Applications

These resistors are commonly used in audio equipment, power amplifiers, and other applications where high energy pulses are present.

B. Metal Film Resistors

1. Description and Characteristics

Metal film resistors are constructed using a thin layer of metal deposited on a ceramic substrate. They offer excellent stability and low noise levels, making them ideal for precision applications.

2. Advantages and Disadvantages

**Advantages:**

- High accuracy and stability

- Low temperature coefficient

- Low noise

**Disadvantages:**

- More expensive than carbon composition resistors

- Limited power handling capability

3. Common Applications

Metal film resistors are widely used in precision measurement devices, audio equipment, and high-frequency applications.

C. Wirewound Resistors

1. Description and Characteristics

Wirewound resistors are made by winding a metal wire around a ceramic or fiberglass core. They are known for their high power handling capabilities and are often used in high-current applications.

2. Advantages and Disadvantages

**Advantages:**

- High power rating

- Excellent heat dissipation

- Good stability

**Disadvantages:**

- Larger size compared to other types

- Inductive properties can affect performance in high-frequency applications

3. Common Applications

Wirewound resistors are commonly found in power supplies, motor control circuits, and high-power applications.

D. Thick Film Resistors

1. Description and Characteristics

Thick film resistors are made by printing a thick layer of resistive material onto a substrate. They are known for their versatility and are often used in surface mount technology (SMT).

2. Advantages and Disadvantages

**Advantages:**

- Cost-effective

- Suitable for mass production

- Wide range of resistance values

**Disadvantages:**

- Lower precision compared to thin film resistors

- Higher noise levels

3. Common Applications

Thick film resistors are widely used in consumer electronics, automotive applications, and industrial equipment.

E. Thin Film Resistors

1. Description and Characteristics

Thin film resistors are made by depositing a thin layer of resistive material onto a substrate. They offer high precision and stability, making them suitable for demanding applications.

2. Advantages and Disadvantages

**Advantages:**

- High accuracy and stability

- Low temperature coefficient

- Low noise

**Disadvantages:**

- More expensive than thick film resistors

- Limited power handling capability

3. Common Applications

Thin film resistors are commonly used in precision measurement devices, medical equipment, and aerospace applications.

F. Surface Mount Resistors

1. Description and Characteristics

Surface mount resistors are designed for mounting directly onto the surface of printed circuit boards (PCBs). They are compact and suitable for automated assembly processes.

2. Advantages and Disadvantages

**Advantages:**

- Space-saving design

- Suitable for high-density applications

- Compatible with automated manufacturing

**Disadvantages:**

- Limited power handling capability

- More challenging to replace in case of failure

3. Common Applications

Surface mount resistors are widely used in smartphones, tablets, and other compact electronic devices.

IV. Comparison of Resistor L Models

A. Performance Metrics

When comparing different models of Resistor L, several performance metrics come into play, including tolerance, temperature coefficient, and noise levels. Metal film resistors typically offer the best performance in terms of accuracy and stability, while wirewound resistors excel in power handling.

B. Cost Considerations

Cost is a significant factor in selecting resistors. Carbon composition and thick film resistors are generally more affordable, making them suitable for budget-conscious projects. In contrast, metal film and thin film resistors, while more expensive, provide superior performance for critical applications.

C. Suitability for Different Applications

The suitability of each resistor model depends on the specific requirements of the application. For high-precision applications, metal film and thin film resistors are preferred. In contrast, wirewound resistors are ideal for high-power applications, while surface mount resistors are best for compact designs.

V. Future Trends in Resistor L Technology

A. Innovations in Materials and Manufacturing Processes

The future of Resistor L technology is likely to be shaped by innovations in materials and manufacturing processes. Advances in nanotechnology and new composite materials may lead to resistors with improved performance characteristics and reduced sizes.

B. The Impact of Technology on Resistor Design

As electronic devices become more compact and complex, the demand for smaller, more efficient resistors will grow. This will drive the development of new designs that can meet the challenges of modern electronics.

C. Predictions for the Future of Resistor L Models

Looking ahead, we can expect to see a continued evolution of Resistor L models, with a focus on enhancing performance, reducing costs, and improving reliability. The integration of smart technologies may also lead to the development of resistors with built-in monitoring capabilities.

VI. Conclusion

In conclusion, Resistor L is a vital component in electrical engineering, with various models offering unique characteristics and applications. From carbon composition to surface mount resistors, each type has its advantages and disadvantages, making it essential to choose the right one for specific needs. As technology continues to advance, the future of resistor technology looks promising, with innovations that will enhance performance and expand applications.

VII. References

- Suggested readings and resources for further exploration

- Industry standards and guidelines related to resistors

This blog post provides a comprehensive overview of the popular models of Resistor L, highlighting their characteristics, applications, and future trends in the field of electrical engineering. Understanding these models is crucial for engineers and designers as they navigate the complexities of modern electronic circuits.