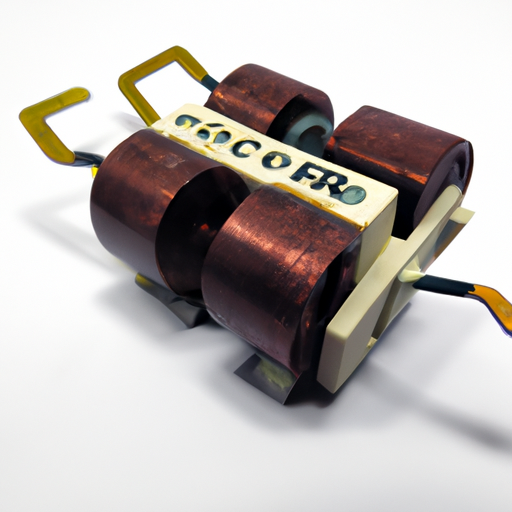

CFR-50JB-52-110R Specialty Transformer: Core Functional Technologies and Application Development Cases

The CFR-50JB-52-110R Specialty Transformer, while not widely recognized in general literature, exemplifies the advancements and applications of specialty transformers designed for unique electrical characteristics. Below, we delve into the core functional technologies and application development cases that highlight the effectiveness of specialty transformers across various industries.

Core Functional Technologies of Specialty Transformers

| 1. Custom Winding Configurations | |

| 2. High Efficiency and Low Loss Design | |

| 3. Isolation and Safety Features | |

| 4. Temperature and Environmental Resilience | |

| 5. Integrated Monitoring and Control Systems | |

| 6. Compact and Lightweight Designs | |

| 1. Renewable Energy Systems | |

| 2. Electric Vehicle Charging Stations | |

| 3. Medical Equipment | |

| 4. Telecommunications | |

| 5. Industrial Automation | |

| 6. Data Centers | |

| 7. Aerospace and Defense |

Application Development Cases

Conclusion

The CFR-50JB-52-110R Specialty Transformer, along with other specialty transformers, plays a vital role in various industries by providing customized solutions that meet specific electrical requirements. Their advanced technologies and diverse applications underscore their importance in enhancing efficiency, safety, and reliability across multiple sectors. As technology continues to advance, the development of specialty transformers will likely expand, addressing emerging challenges and opportunities in the electrical landscape.