The Current Situation of the Grounding Resistor Industry

I. Introduction

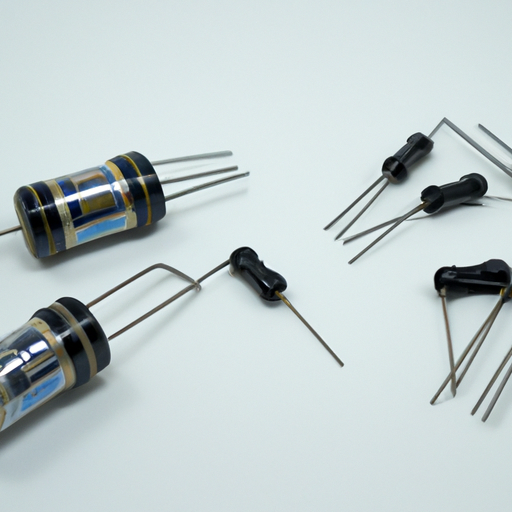

Grounding resistors are critical components in electrical systems, designed to limit fault currents and ensure safety in various applications. By providing a controlled path for fault currents to flow to the ground, these resistors play a vital role in protecting equipment and personnel from electrical hazards. As the demand for reliable and safe electrical systems continues to grow, the grounding resistor industry has evolved significantly. This blog post explores the current situation of the grounding resistor industry, examining its historical context, market landscape, applications, challenges, and future trends.

II. Historical Context

The evolution of grounding technology can be traced back to the early days of electrical engineering. Initially, grounding was a rudimentary practice aimed at preventing electrical shocks and equipment damage. Over the years, advancements in technology and a deeper understanding of electrical systems led to the development of more sophisticated grounding solutions, including grounding resistors.

Key milestones in the grounding resistor industry include the introduction of standardized testing methods and the establishment of regulatory frameworks that govern grounding practices. These developments have been crucial in ensuring the safety and reliability of electrical systems. Regulatory bodies, such as the National Electrical Code (NEC) in the United States and the International Electrotechnical Commission (IEC) globally, have established guidelines that mandate the use of grounding resistors in specific applications, further solidifying their importance in the industry.

III. Current Market Landscape

A. Market Size and Growth Trends

The grounding resistor market has witnessed significant growth in recent years, driven by the increasing demand for reliable electrical systems across various sectors. According to recent market analyses, the global grounding resistor market is projected to grow at a compound annual growth rate (CAGR) of approximately 5% over the next five years. This growth is fueled by the expansion of power generation and distribution networks, particularly in emerging economies.

1. Global Market Overview

The global market for grounding resistors is characterized by a diverse range of applications, including industrial, commercial, and residential sectors. The increasing focus on renewable energy sources, such as wind and solar power, has also contributed to the demand for grounding resistors, as these systems require robust grounding solutions to ensure safety and compliance.

2. Regional Market Analysis

Regionally, North America and Europe have traditionally dominated the grounding resistor market due to their advanced infrastructure and stringent safety regulations. However, the Asia-Pacific region is emerging as a significant player, driven by rapid industrialization, urbanization, and investments in renewable energy projects. Countries like China and India are witnessing a surge in demand for grounding resistors as they expand their electrical grids and adopt new technologies.

B. Key Players in the Industry

The grounding resistor industry is home to several major manufacturers and suppliers, including companies like Siemens, ABB, Schneider Electric, and Eaton. These industry leaders are continuously innovating and expanding their product offerings to meet the evolving needs of the market.

1. Major Manufacturers and Suppliers

These established companies have a strong presence in the market, leveraging their expertise and resources to develop high-quality grounding resistors. They often collaborate with research institutions and industry organizations to stay at the forefront of technological advancements.

2. Emerging Companies and Startups

In addition to established players, a number of emerging companies and startups are entering the grounding resistor market, bringing fresh ideas and innovative solutions. These companies often focus on niche applications or specific technologies, contributing to the overall growth and diversification of the industry.

C. Product Types and Innovations

Grounding resistors can be categorized into fixed and variable types, each serving different applications. Fixed grounding resistors are commonly used in power generation and distribution systems, while variable grounding resistors offer flexibility in adjusting resistance levels based on specific requirements.

1. Fixed vs. Variable Grounding Resistors

Fixed grounding resistors provide a consistent level of resistance, making them suitable for applications where fault current levels are predictable. In contrast, variable grounding resistors allow for adjustments in resistance, making them ideal for dynamic systems where fault currents may fluctuate.

2. Advancements in Materials and Technology

Recent advancements in materials and technology have led to the development of more efficient and durable grounding resistors. Innovations such as the use of composite materials and improved manufacturing processes have enhanced the performance and longevity of these components, making them more reliable in demanding environments.

IV. Applications of Grounding Resistors

Grounding resistors find applications across various sectors, each with unique requirements and challenges.

A. Industrial Applications

1. Power Generation and Distribution

In industrial settings, grounding resistors are essential for power generation and distribution systems. They help manage fault currents, ensuring the safety of personnel and equipment. As industries increasingly adopt renewable energy sources, the need for effective grounding solutions has become even more critical.

2. Renewable Energy Systems

Grounding resistors play a vital role in renewable energy systems, such as wind and solar farms. These systems require robust grounding solutions to protect against electrical faults and ensure compliance with safety regulations.

B. Commercial Applications

1. Data Centers

Data centers, which house critical IT infrastructure, rely on grounding resistors to maintain electrical safety and prevent equipment damage. The increasing demand for data storage and processing capabilities has led to a surge in the construction of new data centers, further driving the need for effective grounding solutions.

2. Telecommunications

In the telecommunications sector, grounding resistors are used to protect sensitive equipment from electrical surges and faults. As the demand for reliable communication networks continues to grow, the importance of grounding resistors in this industry cannot be overstated.

C. Residential Applications

1. Home Electrical Systems

Grounding resistors are also used in residential electrical systems to ensure safety and compliance with electrical codes. Homeowners are increasingly aware of the importance of grounding, leading to a growing market for residential grounding solutions.

2. Safety and Compliance

As safety regulations become more stringent, the demand for grounding resistors in residential applications is expected to rise. Homeowners and builders are prioritizing compliance with electrical codes, further driving the growth of the grounding resistor market.

V. Challenges Facing the Grounding Resistor Industry

Despite the positive growth trends, the grounding resistor industry faces several challenges that could impact its future trajectory.

A. Technological Challenges

1. Integration with Smart Grid Technologies

The rise of smart grid technologies presents both opportunities and challenges for the grounding resistor industry. While smart grids offer enhanced monitoring and control capabilities, integrating grounding resistors into these systems requires advanced technology and expertise.

2. Aging Infrastructure

Many electrical systems around the world are aging, leading to increased maintenance and replacement needs. The grounding resistor industry must address the challenges associated with retrofitting existing systems to meet modern safety standards.

B. Regulatory and Compliance Issues

1. Standards and Certifications

The grounding resistor industry is subject to various standards and certifications that govern product quality and safety. Navigating these regulations can be complex, particularly for emerging companies seeking to enter the market.

2. Environmental Regulations

As environmental concerns grow, the grounding resistor industry must adapt to new regulations aimed at reducing environmental impact. This may involve the development of more sustainable materials and practices.

C. Market Competition and Pricing Pressures

The grounding resistor market is becoming increasingly competitive, with new entrants and established players vying for market share. Pricing pressures may arise as companies seek to differentiate themselves through cost-effective solutions.

VI. Future Trends and Opportunities

The grounding resistor industry is poised for continued growth, driven by several key trends and opportunities.

A. Innovations in Grounding Resistor Technology

1. Smart Grounding Solutions

The integration of smart technologies into grounding solutions is expected to enhance monitoring and control capabilities. Smart grounding solutions can provide real-time data on fault currents, enabling proactive maintenance and improved safety.

2. Sustainable Materials and Practices

As sustainability becomes a priority across industries, the grounding resistor market is likely to see increased demand for environmentally friendly materials and practices. Companies that prioritize sustainability may gain a competitive advantage.

B. Growth Opportunities in Emerging Markets

1. Asia-Pacific and Latin America

Emerging markets, particularly in Asia-Pacific and Latin America, present significant growth opportunities for the grounding resistor industry. As these regions invest in infrastructure and renewable energy projects, the demand for grounding solutions is expected to rise.

2. Expansion in Renewable Energy Sectors

The global shift towards renewable energy sources is creating new opportunities for grounding resistor manufacturers. As more countries adopt clean energy technologies, the need for effective grounding solutions will continue to grow.

C. The Role of Digitalization and IoT in the Industry

The increasing adoption of digitalization and the Internet of Things (IoT) in electrical systems is transforming the grounding resistor industry. IoT-enabled grounding solutions can provide valuable insights into system performance, enabling better decision-making and improved safety.

VII. Conclusion

In summary, the grounding resistor industry is experiencing significant growth, driven by the increasing demand for reliable electrical systems across various sectors. As technology continues to evolve, grounding resistors will play a crucial role in ensuring safety and compliance in electrical applications. The industry's trajectory is promising, with opportunities for innovation and expansion in emerging markets. As we move forward, the importance of grounding resistors in future electrical systems cannot be overstated, making it essential for industry stakeholders to stay informed and adapt to changing market dynamics.

VIII. References

1. Academic journals and articles on grounding technology and electrical safety.

2. Industry reports and market analyses from reputable sources.

3. Regulatory documents and standards publications from organizations such as the NEC and IEC.

This comprehensive overview of the grounding resistor industry highlights its current situation, challenges, and future opportunities, providing valuable insights for stakeholders and interested parties.