What are the Product Features of Metal Resistors?

I. Introduction

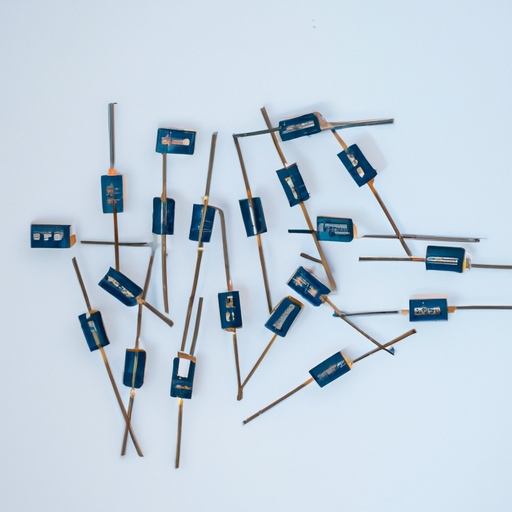

A. Definition of Metal Resistors

Metal resistors are passive electronic components that limit the flow of electric current in a circuit. They are made from metallic materials, which provide a stable and precise resistance value. These resistors are essential in various electronic applications, ensuring that circuits function correctly by controlling voltage and current levels.

B. Importance of Resistors in Electronic Circuits

Resistors play a crucial role in electronic circuits by managing current flow, dividing voltages, and protecting sensitive components from excessive current. They are fundamental in designing circuits for consumer electronics, industrial machinery, automotive systems, and more. The choice of resistor type can significantly impact the performance and reliability of an electronic device.

C. Overview of the Article

This article will explore the various types of metal resistors, their key features, advantages, disadvantages, and applications. By understanding these aspects, engineers and hobbyists can make informed decisions when selecting resistors for their projects.

II. Types of Metal Resistors

1. Construction and Composition

Metal film resistors are made by depositing a thin layer of metal onto a ceramic substrate. The resistance value is determined by the thickness and length of the metal film. This construction allows for precise resistance values and tight tolerances.

2. Applications

These resistors are commonly used in applications requiring high precision, such as audio equipment, instrumentation, and precision measurement devices.

1. Construction and Composition

Metal oxide resistors are constructed using a metal oxide film, typically tin oxide, which is deposited on a ceramic substrate. This type of resistor is known for its stability and reliability under varying environmental conditions.

2. Applications

Metal oxide resistors are often used in high-temperature applications and power circuits, such as power supplies and motor controls.

1. Construction and Composition

Wirewound resistors are made by winding a metal wire, usually made of nickel-chromium alloy, around a ceramic or fiberglass core. This construction allows for high power ratings and excellent heat dissipation.

2. Applications

These resistors are ideal for applications requiring high power handling, such as power amplifiers, load testing, and industrial equipment.

III. Key Features of Metal Resistors

1. Range of Resistance Values

Metal resistors are available in a wide range of resistance values, from a few ohms to several megaohms. This versatility allows engineers to select the appropriate resistor for their specific application.

2. Tolerance Levels

Metal resistors typically offer low tolerance levels, often as tight as ±1% or ±0.1%. This precision is crucial in applications where accuracy is paramount.

1. Definition and Importance

The temperature coefficient of a resistor indicates how its resistance changes with temperature. A low temperature coefficient means that the resistor's performance remains stable across a wide temperature range.

2. Comparison with Other Resistor Types

Metal resistors generally have a lower temperature coefficient compared to carbon resistors, making them more suitable for precision applications where temperature variations can affect performance.

1. Definition and Importance

The power rating of a resistor indicates the maximum amount of power it can dissipate without overheating. This feature is critical in ensuring the longevity and reliability of the resistor in a circuit.

2. Power Dissipation Capabilities

Metal resistors, especially wirewound types, can handle higher power levels compared to other resistor types, making them ideal for high-power applications.

1. Long-term Performance

Metal resistors are known for their long-term stability, maintaining their resistance values over time. This reliability is essential in applications where consistent performance is required.

2. Environmental Resistance

Many metal resistors are designed to withstand harsh environmental conditions, including humidity, temperature fluctuations, and mechanical stress, ensuring they perform reliably in various settings.

1. Types of Noise

Resistors can introduce noise into a circuit, which can affect performance. Metal resistors typically exhibit lower noise levels compared to carbon resistors, making them preferable in sensitive applications.

2. Impact on Circuit Performance

The low noise characteristics of metal resistors contribute to improved signal integrity in audio and communication systems, enhancing overall circuit performance.

IV. Advantages of Metal Resistors

A. Precision and Accuracy

Metal resistors provide high precision and accuracy, making them suitable for applications that require exact resistance values. Their tight tolerances ensure that circuits operate as intended.

B. Low Temperature Coefficient

The low temperature coefficient of metal resistors ensures stable performance across varying temperatures, reducing the risk of circuit malfunction due to temperature changes.

C. High Power Handling Capability

Metal resistors, particularly wirewound types, can handle significant power levels, making them ideal for high-power applications where other resistor types may fail.

D. Wide Range of Applications

The versatility of metal resistors allows them to be used in various applications, from consumer electronics to industrial machinery, making them a popular choice among engineers.

E. Durability and Longevity

Metal resistors are built to last, with many designed to withstand harsh environmental conditions. Their durability ensures long-term performance, reducing the need for frequent replacements.

V. Disadvantages of Metal Resistors

A. Cost Considerations

Metal resistors tend to be more expensive than carbon resistors, which may be a consideration for budget-sensitive projects. However, the benefits of precision and reliability often justify the higher cost.

B. Size and Form Factor

Some metal resistors, particularly wirewound types, can be larger than other resistor types. This size may pose challenges in compact circuit designs where space is limited.

C. Limited Availability in Certain Values

While metal resistors are available in a wide range of values, specific resistance values may not be as readily available as those for carbon resistors, potentially limiting options for some applications.

VI. Applications of Metal Resistors

A. Consumer Electronics

Metal resistors are widely used in consumer electronics, including audio equipment, televisions, and computers, where precision and reliability are essential.

B. Industrial Equipment

In industrial settings, metal resistors are employed in machinery and control systems, ensuring stable performance under demanding conditions.

C. Automotive Applications

Metal resistors are used in automotive electronics, including engine control units and sensor systems, where durability and accuracy are critical.

D. Telecommunications

In telecommunications, metal resistors help maintain signal integrity in communication devices, ensuring clear and reliable transmission.

E. Medical Devices

Metal resistors are essential in medical devices, where precision and reliability can directly impact patient safety and device performance.

VII. Conclusion

A. Summary of Key Features

Metal resistors offer a range of key features, including precise resistance values, low temperature coefficients, high power handling capabilities, and excellent stability. These characteristics make them suitable for various applications across multiple industries.

B. Importance of Choosing the Right Resistor

Selecting the appropriate resistor is crucial for ensuring optimal circuit performance. Engineers must consider factors such as resistance value, power rating, and environmental conditions when making their choice.

C. Future Trends in Metal Resistor Technology

As technology advances, we can expect continued improvements in metal resistor design and manufacturing. Innovations may lead to even greater precision, smaller form factors, and enhanced performance in challenging environments.

VIII. References

A. Academic Journals

- IEEE Transactions on Electron Devices

- Journal of Electronic Materials

B. Industry Publications

- Electronic Design Magazine

- EDN Network

C. Manufacturer Specifications

- Vishay Intertechnology

- Yageo Corporation

In conclusion, understanding the product features of metal resistors is essential for anyone involved in electronics. Their precision, reliability, and versatility make them a preferred choice in many applications, ensuring that circuits function as intended. By considering the various types, key features, advantages, and disadvantages, engineers can make informed decisions that enhance the performance and longevity of their electronic designs.