What is the Price of Popular Neutral Point Grounding Resistor Models in Stock?

I. Introduction

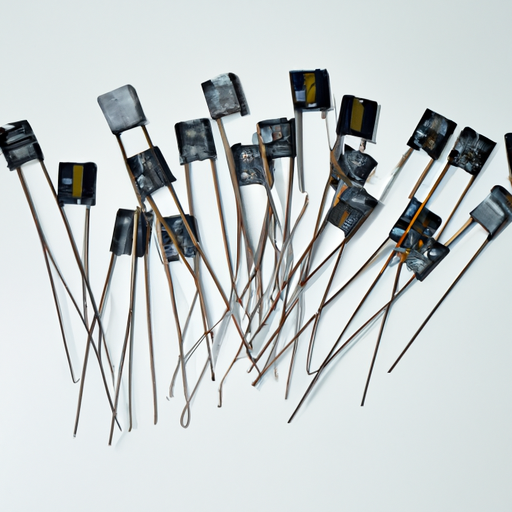

Neutral point grounding resistors (NGRs) play a crucial role in electrical systems, particularly in industrial and commercial applications. These resistors are essential for ensuring the safety and reliability of electrical installations by providing a controlled path for fault currents. This article aims to provide an overview of popular neutral point grounding resistor models currently in stock, along with their prices, to help engineers and procurement professionals make informed decisions.

II. Understanding Neutral Point Grounding

A. Explanation of Grounding in Electrical Systems

Grounding is a fundamental aspect of electrical engineering that involves connecting parts of an electrical system to the ground. This connection helps to stabilize voltage levels, protect equipment, and ensure safety by providing a path for fault currents to dissipate safely into the earth.

B. Types of Grounding Methods

There are several grounding methods used in electrical systems, each with its advantages and disadvantages:

1. **Solid Grounding**: In solid grounding, the neutral point of a transformer or generator is directly connected to the ground. This method provides a low-resistance path for fault currents, which can help in quickly clearing faults. However, it can lead to high fault currents that may damage equipment.

2. **Resistance Grounding**: This method involves connecting the neutral point to the ground through a resistor. Resistance grounding limits the fault current to a safe level, reducing the risk of equipment damage while still allowing for effective fault detection.

3. **Reactance Grounding**: Reactance grounding uses inductors to connect the neutral point to the ground. This method limits fault currents and is often used in systems where high fault currents could be problematic.

C. Role of Neutral Point Grounding Resistors

Neutral point grounding resistors are specifically designed to limit the fault current in resistance-grounded systems. By providing a controlled resistance, these resistors help to protect equipment from damage during fault conditions while allowing for effective monitoring and detection of faults.

III. Popular Neutral Point Grounding Resistor Models

A. Overview of Key Manufacturers

Several manufacturers are known for producing high-quality neutral point grounding resistors. Here are three key players in the market:

1. **Manufacturer A**: Known for its innovative designs and robust products, Manufacturer A offers a range of NGRs suitable for various applications.

2. **Manufacturer B**: With a strong reputation for reliability, Manufacturer B provides NGRs that are widely used in industrial settings.

3. **Manufacturer C**: This manufacturer specializes in custom solutions, catering to specific customer needs with tailored NGR designs.

B. Description of Popular Models

1. **Model 1: Features and Specifications**

- **Power Rating**: 1000 W

- **Resistance Value**: 10 Ω

- **Material**: Stainless steel housing for durability

- **Applications**: Suitable for medium-voltage systems

2. **Model 2: Features and Specifications**

- **Power Rating**: 2000 W

- **Resistance Value**: 5 Ω

- **Material**: Aluminum housing for lightweight applications

- **Applications**: Ideal for industrial automation systems

3. **Model 3: Features and Specifications**

- **Power Rating**: 1500 W

- **Resistance Value**: 15 Ω

- **Material**: Copper alloy for excellent conductivity

- **Applications**: Used in power generation facilities

IV. Pricing Analysis

A. Factors Influencing Prices

The price of neutral point grounding resistors can vary significantly based on several factors:

1. **Material Quality**: Higher-quality materials, such as stainless steel or copper alloys, typically result in higher prices due to their durability and conductivity.

2. **Power Rating**: Resistors with higher power ratings are generally more expensive, as they are designed to handle greater fault currents.

3. **Manufacturer Reputation**: Established manufacturers with a strong reputation for quality and reliability may charge a premium for their products.

B. Price Range of Popular Models

1. **Model 1: Price Range**

- Price: $300 - $500

2. **Model 2: Price Range**

- Price: $400 - $600

3. **Model 3: Price Range**

- Price: $350 - $550

C. Comparison of Prices Across Different Manufacturers

When comparing prices across different manufacturers, it is essential to consider the features and specifications of each model. While one manufacturer may offer a lower price, the quality and performance of the product should also be taken into account. For instance, Manufacturer A's Model 1 may be priced higher than Manufacturer B's Model 2, but if Model 1 offers superior durability and performance, it may be worth the investment.

V. Where to Purchase Neutral Point Grounding Resistors

A. Online Retailers

1. **Overview of Major Online Platforms**: Websites like Amazon, eBay, and specialized electrical supply stores offer a wide range of neutral point grounding resistors. These platforms often provide customer reviews and ratings, which can help in making informed purchasing decisions.

2. **Price Comparison Tools**: Online tools and websites allow users to compare prices across different retailers, ensuring they get the best deal available.

B. Local Electrical Supply Stores

Local electrical supply stores often carry a selection of neutral point grounding resistors. Visiting these stores can provide the advantage of speaking directly with knowledgeable staff who can offer advice and recommendations based on specific needs.

C. Direct Purchase from Manufacturers

For those looking for custom solutions or bulk purchases, contacting manufacturers directly can be beneficial. Many manufacturers offer tailored products and may provide discounts for larger orders.

VI. Conclusion

A. Summary of Key Points

Neutral point grounding resistors are essential components in electrical systems, providing safety and reliability by limiting fault currents. Understanding the different types of grounding methods and the role of NGRs is crucial for selecting the right model for specific applications.

B. Importance of Choosing the Right Model

Choosing the right neutral point grounding resistor involves considering factors such as power rating, material quality, and manufacturer reputation. The right choice can significantly impact the safety and efficiency of electrical systems.

C. Final Thoughts on Pricing and Availability

With a range of models available from various manufacturers, prices can vary widely. By understanding the factors that influence pricing and exploring different purchasing options, engineers and procurement professionals can make informed decisions that meet their specific needs.

VII. References

A. List of Sources for Further Reading

1. IEEE Standards on Grounding Practices

2. Manufacturer Product Catalogs

3. Electrical Engineering Textbooks

B. Manufacturer Websites and Product Catalogs

1. Manufacturer A: [Website Link]

2. Manufacturer B: [Website Link]

3. Manufacturer C: [Website Link]

This comprehensive overview of neutral point grounding resistors and their pricing provides valuable insights for anyone involved in electrical system design and procurement. By understanding the market and the available options, stakeholders can ensure they select the best products for their needs.