What are the Popular Models of Resistor 2?

I. Introduction

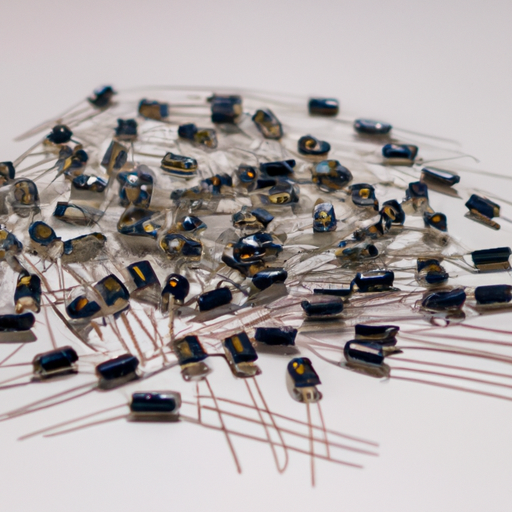

In the world of electronics, resistors play a crucial role in controlling the flow of electric current. Among the various types of resistors, Resistor 2 has gained significant attention due to its unique features and applications. This article aims to explore the popular models of Resistor 2, their specifications, applications, and how to choose the right model for specific needs.

II. Understanding Resistor 2

A. Basic Principles of Resistors

Resistors are passive electronic components that limit the flow of electric current in a circuit. The fundamental principle governing resistors is Ohm's Law, which states that the current (I) flowing through a conductor between two points is directly proportional to the voltage (V) across the two points and inversely proportional to the resistance (R) of the conductor. This relationship can be expressed with the formula:

\[ V = I \times R \]

Resistors serve various functions in electronic circuits, including voltage division, current limiting, and signal conditioning.

B. Types of Resistors

Resistors can be categorized into several types based on their construction and functionality:

1. **Fixed Resistors**: These resistors have a constant resistance value and are widely used in circuits where precise resistance is required.

2. **Variable Resistors**: Also known as potentiometers or rheostats, these resistors allow users to adjust the resistance value according to their needs.

3. **Specialty Resistors**: These include thermistors, photoresistors, and other types designed for specific applications.

III. Popular Models of Resistor 2

A. Overview of Resistor 2 Models

Resistor 2 encompasses a range of models, each designed with unique features to cater to different applications. These models are engineered to meet specific performance metrics, making them suitable for various fields, including consumer electronics, automotive, and industrial applications.

B. Model 1: Resistor 2 Standard

1. **Specifications**: The Resistor 2 Standard model typically features a resistance range from 1 ohm to 10 megaohms, with a tolerance of ±5%.

2. **Applications**: This model is commonly used in general-purpose applications, such as voltage dividers and current limiting in basic electronic circuits.

3. **Advantages and Disadvantages**: The advantages of the Resistor 2 Standard include its affordability and wide availability. However, its tolerance may not be suitable for precision applications.

C. Model 2: Resistor 2 Precision

1. **Specifications**: The Resistor 2 Precision model offers tighter tolerances, often around ±1% or better, and is available in a similar resistance range as the standard model.

2. **Applications**: This model is ideal for applications requiring high accuracy, such as instrumentation and measurement devices.

3. **Advantages and Disadvantages**: The main advantage of the Resistor 2 Precision is its accuracy, making it suitable for sensitive applications. However, it tends to be more expensive than standard models.

D. Model 3: Resistor 2 High-Power

1. **Specifications**: Designed to handle higher power levels, the Resistor 2 High-Power model can typically dissipate power ratings from 1 watt to over 100 watts.

2. **Applications**: This model is used in power electronics, such as power supplies and amplifiers, where high current flow is expected.

3. **Advantages and Disadvantages**: The advantage of this model is its ability to handle high power without overheating. However, it may be bulkier and more expensive than lower-power models.

E. Model 4: Resistor 2 Surface Mount

1. **Specifications**: The Resistor 2 Surface Mount model is designed for compact applications, featuring small sizes and low profiles.

2. **Applications**: Commonly used in modern electronics, such as smartphones and tablets, where space is limited.

3. **Advantages and Disadvantages**: The main advantage is its space-saving design, but it may require specialized mounting techniques and can be more challenging to replace.

F. Model 5: Resistor 2 Network

1. **Specifications**: This model consists of multiple resistors integrated into a single package, allowing for complex resistance configurations.

2. **Applications**: Resistor 2 Networks are used in applications requiring multiple resistances, such as in filters and signal processing circuits.

3. **Advantages and Disadvantages**: The advantage is the reduction in board space and improved reliability. However, they can be more complex to design and may have limited flexibility compared to discrete resistors.

IV. Comparison of Resistor 2 Models

A. Performance Metrics

When comparing the various models of Resistor 2, several performance metrics should be considered:

1. **Tolerance Levels**: Precision models offer tighter tolerances, making them suitable for applications where accuracy is critical.

2. **Temperature Coefficients**: Different models have varying temperature coefficients, affecting their performance in fluctuating temperatures.

B. Cost Analysis

Cost is a significant factor when selecting a resistor model. Standard models are generally more affordable, while precision and high-power models tend to be more expensive due to their specialized features.

C. Suitability for Different Applications

Each model has its strengths and weaknesses, making them suitable for different applications. For instance, precision models are ideal for measurement devices, while high-power models are necessary for power electronics.

V. Choosing the Right Resistor 2 Model

A. Factors to Consider

When selecting the right Resistor 2 model, several factors should be taken into account:

1. **Application Requirements**: Consider the specific needs of your application, such as resistance value, tolerance, and power rating.

2. **Environmental Conditions**: Assess the operating environment, including temperature and humidity, which can affect resistor performance.

3. **Budget Constraints**: Determine your budget, as some models may be more expensive than others.

B. Recommendations for Specific Use Cases

- For general-purpose applications, the Resistor 2 Standard model is often sufficient.

- For high-accuracy applications, the Resistor 2 Precision model is recommended.

- In power electronics, the Resistor 2 High-Power model is essential.

- For compact designs, consider the Resistor 2 Surface Mount model.

- For complex resistance needs, the Resistor 2 Network model is ideal.

VI. Conclusion

Selecting the right Resistor 2 model is crucial for ensuring optimal performance in electronic circuits. Each model offers unique features and specifications tailored to specific applications. As technology advances, we can expect further innovations in resistor technology, enhancing their performance and expanding their applications. Understanding the various models of Resistor 2 will empower engineers and hobbyists alike to make informed decisions, ultimately impacting the efficiency and reliability of electronic devices.

VII. References

- "Electronic Components: A Complete Reference for Project Builders" by Mark J. Smith

- "The Art of Electronics" by Paul Horowitz and Winfield Hill

- Online resources from electronics manufacturers and component distributors.

This comprehensive overview of Resistor 2 models provides a solid foundation for understanding their significance in electronics and guides readers in selecting the appropriate model for their needs.