The Production Process of Mainstream Resistor Factories

I. Introduction

Resistors are fundamental components in electronic circuits, serving the crucial role of controlling current flow and voltage levels. They are essential for the proper functioning of a wide array of devices, from simple household electronics to complex industrial machinery. The resistor manufacturing industry has evolved significantly over the years, driven by advancements in technology and increasing demand for high-performance components. This article aims to explore the production process of mainstream resistor factories, shedding light on the intricate steps involved in creating these vital components.

II. Types of Resistors

Resistors come in various types, each designed for specific applications and performance characteristics.

A. Fixed Resistors

1. **Carbon Composition Resistors**: These resistors are made from a mixture of carbon and a binding material. They are known for their high energy absorption and are often used in applications where high pulse loads are expected.

2. **Film Resistors**: This category includes carbon film and metal film resistors. Carbon film resistors are made by depositing a thin layer of carbon on a ceramic substrate, while metal film resistors use a thin layer of metal. Both types offer excellent stability and low noise.

3. **Wirewound Resistors**: Constructed by winding a metal wire around a ceramic or fiberglass core, wirewound resistors are known for their high precision and ability to handle high power levels.

B. Variable Resistors

1. **Potentiometers**: These resistors allow for adjustable resistance and are commonly used in volume controls and tuning circuits.

2. **Rheostats**: Similar to potentiometers, rheostats are used to control current flow in a circuit, but they typically handle higher power levels.

C. Specialty Resistors

1. **Thermistors**: These temperature-sensitive resistors change resistance with temperature variations and are widely used in temperature sensing applications.

2. **Photoresistors**: Also known as light-dependent resistors (LDRs), these components change resistance based on light exposure, making them ideal for light-sensing applications.

III. Raw Materials Used in Resistor Production

The production of resistors requires a variety of raw materials, each contributing to the performance and reliability of the final product.

A. Conductive Materials

1. **Carbon**: Used primarily in carbon composition and carbon film resistors, carbon provides a stable and reliable conductive medium.

2. **Metal Oxides**: Commonly used in metal film resistors, metal oxides offer excellent thermal stability and resistance to environmental factors.

3. **Metal Wires**: Essential for wirewound resistors, metal wires (often made of nickel-chromium alloys) provide the necessary conductivity and durability.

B. Insulating Materials

1. **Ceramics**: Used as substrates for various types of resistors, ceramics provide excellent insulation and thermal stability.

2. **Epoxy Resins**: These materials are often used for coating and encapsulating resistors, providing protection against moisture and mechanical stress.

C. Other Components

1. **Lead Wires**: These are used to connect resistors to circuits, ensuring reliable electrical connections.

2. **Protective Coatings**: Coatings are applied to resistors to enhance durability and protect against environmental factors.

IV. The Production Process

The production of resistors involves several key steps, each critical to ensuring the quality and performance of the final product.

A. Design and Engineering

1. **Specifications and Requirements**: The process begins with defining the specifications for the resistors, including resistance values, tolerance levels, and environmental conditions.

2. **Prototyping and Testing**: Engineers create prototypes to test the design and performance, making adjustments as necessary to meet the required standards.

B. Material Preparation

1. **Sourcing and Quality Control of Raw Materials**: Manufacturers source high-quality raw materials from reliable suppliers, conducting rigorous quality control checks to ensure compliance with industry standards.

2. **Pre-processing of Materials**: This may involve grinding, mixing, and other processes to prepare the materials for manufacturing.

C. Manufacturing Techniques

1. **Carbon Composition Resistors**:

- **Mixing and Molding**: The carbon and binding materials are mixed and molded into the desired shape.

- **Curing and Cutting**: The molded resistors are cured to harden the material and then cut to the required dimensions.

2. **Film Resistors**:

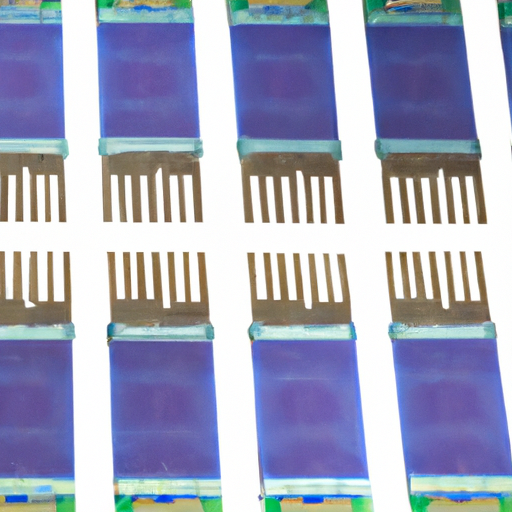

- **Thin-film Deposition Techniques**: A thin layer of carbon or metal is deposited onto a ceramic substrate using techniques such as sputtering or chemical vapor deposition.

- **Laser Trimming**: Precision laser trimming is used to achieve the desired resistance value by removing material from the film.

3. **Wirewound Resistors**:

- **Winding and Forming**: Metal wire is wound around a core to create the resistor element.

- **Insulation and Coating**: The wound resistor is insulated and coated to protect it from environmental factors.

D. Assembly and Packaging

1. **Component Assembly**: The various components of the resistors are assembled, including lead wires and protective coatings.

2. **Quality Assurance and Testing**: Each batch of resistors undergoes rigorous testing to ensure they meet the specified performance criteria.

3. **Packaging for Distribution**: Finally, the resistors are packaged for distribution, ensuring they are protected during transport.

V. Quality Control Measures

Quality control is a critical aspect of resistor manufacturing, ensuring that each component meets industry standards and customer expectations.

A. In-process Inspections

Manufacturers conduct regular inspections throughout the production process to identify and address any issues early on.

B. Final Testing Procedures

Before packaging, resistors undergo final testing to verify their resistance values, tolerance levels, and overall performance.

C. Compliance with Industry Standards

Manufacturers adhere to various industry standards, such as ISO and RoHS, to ensure their products are safe and reliable.

VI. Environmental Considerations

As the electronics industry grows, so does the need for sustainable practices in resistor manufacturing.

A. Waste Management and Recycling

Factories implement waste management systems to minimize waste and promote recycling of materials.

B. Energy Consumption and Sustainability Practices

Manufacturers are increasingly adopting energy-efficient practices and technologies to reduce their carbon footprint.

C. Regulatory Compliance and Environmental Impact Assessments

Compliance with environmental regulations is essential, and manufacturers conduct impact assessments to evaluate their operations' effects on the environment.

VII. Future Trends in Resistor Manufacturing

The resistor manufacturing industry is poised for significant advancements in the coming years.

A. Advances in Materials Science

Research into new materials may lead to the development of resistors with improved performance characteristics and reliability.

B. Automation and Industry 4.0

The integration of automation and smart manufacturing technologies is expected to enhance production efficiency and reduce costs.

C. Customization and Demand for High-Performance Resistors

As electronic devices become more sophisticated, the demand for customized and high-performance resistors will continue to grow.

VIII. Conclusion

The production process of mainstream resistor factories is a complex and multifaceted endeavor that requires careful planning, quality control, and adherence to industry standards. From the initial design and engineering phases to the final assembly and packaging, each step plays a vital role in ensuring the reliability and performance of resistors. As the industry evolves, the importance of quality and innovation will remain paramount, paving the way for a future where resistors continue to meet the demands of an increasingly electronic world.

IX. References

- Academic journals and articles on resistor technology and manufacturing processes.

- Industry reports and white papers detailing trends and advancements in the electronics sector.

- Manufacturer websites and technical documentation providing insights into specific resistor types and production methods.

This comprehensive overview of the resistor production process highlights the intricate steps involved in creating these essential components, emphasizing the importance of quality, sustainability, and innovation in the industry.