Sensitive Resistor Product Training Precautions

I. Introduction

Sensitive resistors are crucial components in various electronic applications, serving as the backbone for many devices that require precise measurements and control. These resistors are designed to respond to small changes in voltage or current, making them essential in fields such as telecommunications, automotive, and medical devices. However, the handling and training associated with sensitive resistors require careful attention to detail. This blog post will explore the importance of proper training, the characteristics of sensitive resistors, and the precautions necessary to ensure safe and effective use.

II. Understanding Sensitive Resistors

A. What are Sensitive Resistors?

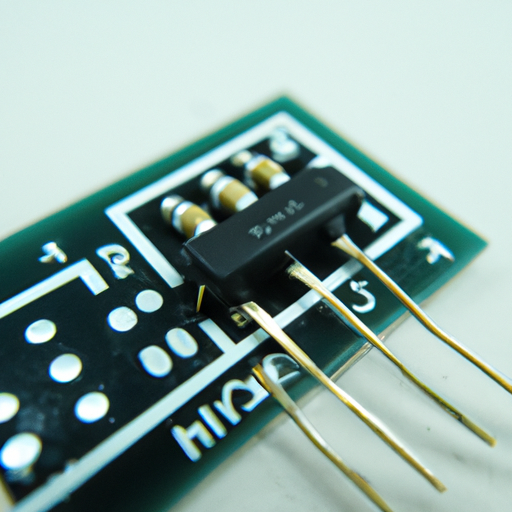

Sensitive resistors, often referred to as precision resistors, are components that exhibit a high degree of sensitivity to changes in electrical signals. They can be categorized into several types, including thermistors, photoresistors, and strain gauges, each serving unique functions in various applications.

1. **Types of Sensitive Resistors**:

- **Thermistors**: These resistors change resistance with temperature variations, making them ideal for temperature sensing applications.

- **Photoresistors**: Also known as light-dependent resistors (LDRs), these components change resistance based on light exposure, commonly used in light-sensing applications.

- **Strain Gauges**: These resistors measure deformation or strain in materials, widely used in structural health monitoring.

2. **Applications in Various Industries**:

Sensitive resistors find applications in numerous industries, including:

- **Telecommunications**: For signal processing and transmission.

- **Automotive**: In engine control units for monitoring temperature and pressure.

- **Medical Devices**: For precise measurements in diagnostic equipment.

B. Characteristics of Sensitive Resistors

Understanding the characteristics of sensitive resistors is essential for their effective use.

1. **Sensitivity**: This refers to the resistor's ability to respond to small changes in voltage or current. Higher sensitivity allows for more accurate measurements.

2. **Temperature Coefficient**: This characteristic indicates how much the resistance changes with temperature. A low temperature coefficient is desirable for stable performance across varying temperatures.

3. **Resistance Range**: Sensitive resistors come in various resistance values, and selecting the appropriate range is crucial for specific applications.

III. Importance of Training in Handling Sensitive Resistors

A. Risks Associated with Improper Handling

Improper handling of sensitive resistors can lead to significant risks, including:

1. **Damage to Components**: Mishandling can result in physical damage to the resistors, leading to inaccurate readings or complete failure.

2. **Safety Hazards**: In some applications, sensitive resistors are part of high-voltage systems. Improper handling can pose electrical hazards to personnel.

B. Benefits of Proper Training

Investing in proper training yields numerous benefits:

1. **Enhanced Performance**: Trained personnel are more likely to handle sensitive resistors correctly, ensuring optimal performance in applications.

2. **Increased Longevity of Equipment**: Proper handling and maintenance can extend the lifespan of sensitive resistors and the devices they are integrated into.

IV. Precautions During Training

A. Pre-Training Preparations

Before training begins, several preparations should be made:

1. **Understanding the Equipment**: Trainees should familiarize themselves with the specific types of sensitive resistors they will be working with, including their specifications and applications.

2. **Safety Gear and Environment**: Ensuring that the training environment is safe and that all participants wear appropriate safety gear is crucial.

B. Training Content

A comprehensive training program should include:

1. **Theoretical Knowledge**: Trainees should learn about the principles of operation, characteristics, and applications of sensitive resistors.

2. **Practical Demonstrations**: Demonstrations of proper handling techniques and equipment usage should be conducted to reinforce theoretical knowledge.

C. Hands-On Training

Hands-on training is vital for effective learning:

1. **Proper Handling Techniques**: Trainees should practice handling sensitive resistors with care, learning to avoid physical damage and contamination.

2. **Calibration Procedures**: Understanding how to calibrate sensitive resistors is essential for ensuring accurate measurements.

V. Key Precautions When Using Sensitive Resistors

A. Environmental Considerations

Environmental factors play a significant role in the performance of sensitive resistors:

1. **Temperature and Humidity Control**: Maintaining a stable environment is crucial, as fluctuations can affect resistance values.

2. **Electrostatic Discharge (ESD) Protection**: Sensitive resistors are susceptible to damage from ESD. Implementing ESD protection measures, such as grounding and using ESD-safe materials, is essential.

B. Handling and Storage

Proper handling and storage practices can prevent damage:

1. **Proper Packaging**: Sensitive resistors should be stored in anti-static packaging to protect them from ESD and physical damage.

2. **Avoiding Contamination**: Ensuring that resistors are kept clean and free from contaminants is vital for maintaining their performance.

C. Testing and Calibration

Regular testing and calibration are essential for optimal performance:

1. **Importance of Regular Testing**: Routine testing helps identify any issues early, ensuring that sensitive resistors function correctly.

2. **Calibration Techniques**: Understanding and applying proper calibration techniques is crucial for maintaining accuracy in measurements.

VI. Common Mistakes and How to Avoid Them

A. Overlooking Manufacturer Guidelines

One of the most common mistakes is ignoring the manufacturer's guidelines. Always refer to the specifications and recommendations provided by the manufacturer to ensure proper handling and usage.

B. Ignoring Environmental Factors

Failing to consider environmental factors, such as temperature and humidity, can lead to inaccurate measurements and damage. Always monitor and control the environment in which sensitive resistors are used.

C. Inadequate Training and Knowledge

Inadequate training can result in improper handling and increased risk of damage. Ensure that all personnel receive comprehensive training before working with sensitive resistors.

VII. Conclusion

In conclusion, sensitive resistors are vital components in many electronic applications, and proper training in their handling is essential. By understanding their characteristics, the importance of training, and the precautions necessary for safe use, organizations can enhance performance and extend the longevity of their equipment. Continuous education and ongoing training are crucial in maintaining awareness of best practices and evolving technologies. As the industry advances, staying informed and prepared will ensure that sensitive resistors continue to perform optimally in their applications.

VIII. References

A. Suggested Reading Materials

- "Fundamentals of Electronic Components" by John Doe

- "Precision Resistors: Theory and Applications" by Jane Smith

B. Relevant Industry Standards and Guidelines

- International Electrotechnical Commission (IEC) Standards

- American National Standards Institute (ANSI) Guidelines

By adhering to these precautions and fostering a culture of continuous learning, organizations can ensure the safe and effective use of sensitive resistors in their applications.