Manufacturing Processes of the Latest Resistor Manufacturers

I. Introduction

Resistors are fundamental components in electronic circuits, serving the critical function of controlling current flow and voltage levels. Their importance cannot be overstated, as they are essential for the proper functioning of virtually all electronic devices, from simple household appliances to complex computing systems. The resistor manufacturing industry has evolved significantly over the years, driven by advancements in technology and the increasing demand for high-performance electronic components. This article aims to explore the latest manufacturing processes employed by resistor manufacturers, shedding light on the innovations and techniques that define the modern landscape of resistor production.

II. Types of Resistors

Resistors come in various types, each designed for specific applications and performance requirements. Understanding these types is crucial for appreciating the manufacturing processes involved.

A. Fixed Resistors

1. **Carbon Composition Resistors**: These resistors are made from a mixture of carbon particles and a binding resin. They are known for their high energy absorption and are often used in applications where high pulse loads are expected.

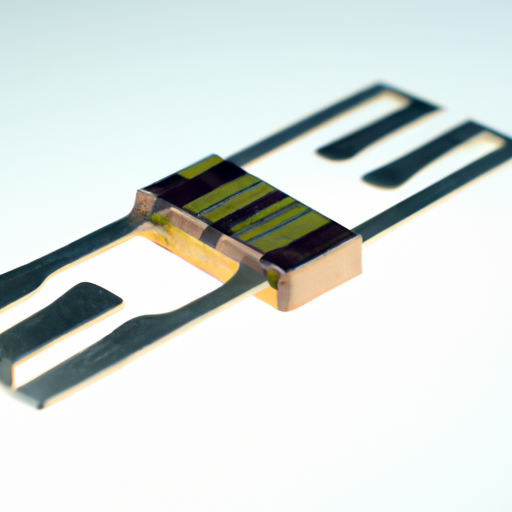

2. **Film Resistors**: This category includes carbon film and metal film resistors. Film resistors are created by depositing a thin layer of resistive material onto a substrate. They offer better precision and stability compared to carbon composition resistors.

3. **Wirewound Resistors**: Made by winding a metal wire around a ceramic or fiberglass core, wirewound resistors are known for their high power ratings and precision. They are commonly used in applications requiring high accuracy and stability.

B. Variable Resistors

1. **Potentiometers**: These adjustable resistors allow users to change resistance levels manually. They are widely used in volume controls and other applications requiring variable resistance.

2. **Rheostats**: Similar to potentiometers, rheostats are used to control current flow in a circuit. They are typically used in applications where high power is involved.

C. Specialty Resistors

1. **Precision Resistors**: Designed for high accuracy and low tolerance, precision resistors are used in applications where exact resistance values are critical.

2. **Power Resistors**: These resistors are built to handle high power levels and are often used in power electronics and industrial applications.

III. Overview of Manufacturing Processes

The manufacturing of resistors involves several key processes, starting with raw material selection and design.

A. Raw Material Selection

The choice of materials is crucial in resistor manufacturing. Common materials include carbon, metal, and ceramic. The quality of these materials directly impacts the performance and reliability of the final product. For instance, high-purity metals are essential for film resistors to ensure accurate resistance values.

B. Design and Engineering

Modern resistor design heavily relies on Computer-Aided Design (CAD) software, which allows engineers to create precise models of resistors. Simulation tools are also employed to test and predict resistor performance under various conditions, ensuring that the final product meets the required specifications.

IV. Manufacturing Techniques

The manufacturing techniques used by resistor manufacturers vary depending on the type of resistor being produced.

A. Film Resistor Manufacturing

1. **Thin Film Technology**: This process involves depositing a thin layer of resistive material onto a substrate using methods such as sputtering or evaporation. The deposited film is then trimmed using lasers to achieve precise resistance values.

2. **Thick Film Technology**: In this method, a paste containing resistive materials is screen-printed onto a substrate. The printed resistors are then fired in a kiln to sinter the materials, creating a solid and stable resistor.

B. Wirewound Resistor Manufacturing

The production of wirewound resistors begins with the selection of high-quality wire, which is then wound around a core. Insulation materials are applied to prevent short circuits, and the entire assembly is encapsulated to protect it from environmental factors.

C. Carbon Composition Resistor Manufacturing

The manufacturing of carbon composition resistors involves mixing carbon particles with a binding resin, followed by molding the mixture into the desired shape. The molded resistors are then cured to enhance their mechanical properties and finished to meet specific standards.

V. Quality Control and Testing

Quality assurance is paramount in resistor manufacturing. Manufacturers employ rigorous testing methods to ensure that their products meet industry standards.

A. Importance of Quality Assurance

Quality control processes help identify defects and ensure that resistors perform reliably in their intended applications. This is particularly important in industries such as automotive and aerospace, where component failure can have serious consequences.

B. Testing Methods

1. **Electrical Testing**: Resistors undergo electrical testing to measure resistance values and tolerances. This ensures that they meet the specified performance criteria.

2. **Environmental Testing**: Resistors are also subjected to environmental testing, including exposure to extreme temperatures and humidity, to assess their durability and reliability.

C. Certification and Compliance

Manufacturers must comply with industry standards, such as ISO and RoHS, to ensure that their products are safe and environmentally friendly. Certification from recognized bodies adds credibility to the manufacturer and assures customers of product quality.

VI. Innovations in Resistor Manufacturing

The resistor manufacturing industry is witnessing several innovations that enhance production efficiency and product performance.

A. Automation and Industry 4.0

1. **Use of Robotics**: Automation through robotics has streamlined production processes, reducing labor costs and increasing precision in manufacturing.

2. **Data Analytics**: Manufacturers are leveraging data analytics to optimize production processes, monitor equipment performance, and predict maintenance needs, leading to improved efficiency.

B. Sustainable Manufacturing Practices

1. **Eco-Friendly Materials**: There is a growing trend towards using eco-friendly materials in resistor production, reducing the environmental impact of manufacturing processes.

2. **Waste Reduction**: Manufacturers are implementing waste reduction initiatives, such as recycling scrap materials and optimizing production techniques to minimize waste.

C. Advances in Material Science

1. **New Materials**: Research in material science has led to the development of new materials that offer improved performance characteristics, such as higher thermal stability and lower noise levels.

2. **Nanotechnology Applications**: The application of nanotechnology in resistor manufacturing is paving the way for smaller, more efficient resistors with enhanced performance.

VII. Case Studies of Leading Resistor Manufacturers

A. Manufacturer A: Innovative Techniques and Market Impact

Manufacturer A has adopted advanced thin film technology, allowing them to produce high-precision resistors that cater to the growing demand in the telecommunications sector. Their innovative approach has positioned them as a market leader.

B. Manufacturer B: Sustainability Initiatives and Product Range

Manufacturer B has implemented a comprehensive sustainability program, focusing on eco-friendly materials and waste reduction. Their commitment to sustainability has resonated with environmentally conscious consumers, expanding their market reach.

C. Manufacturer C: Technological Advancements and Future Outlook

Manufacturer C has invested heavily in automation and data analytics, resulting in significant improvements in production efficiency. Their focus on technological advancements positions them well for future growth in the competitive resistor market.

VIII. Conclusion

In summary, the manufacturing processes of resistors have evolved significantly, driven by advancements in technology and the increasing demand for high-performance components. From raw material selection to innovative manufacturing techniques, the industry is continuously adapting to meet the needs of modern electronics. As we look to the future, trends such as automation, sustainability, and material science advancements will play a crucial role in shaping the resistor manufacturing landscape. Continuous innovation will be essential for manufacturers to remain competitive and meet the ever-changing demands of the electronics industry.

IX. References

A comprehensive list of academic papers, industry reports, and manufacturer websites would be included here to support the research and claims made in the article.

---

This blog post provides a detailed overview of the manufacturing processes of the latest resistor manufacturers, highlighting the importance of innovation and quality in the industry. Each section can be further expanded with specific examples and data to enhance the depth of the content.