What are the Main Application Directions of Metal Film Resistors?

I. Introduction

In the world of electronics, resistors play a crucial role in controlling the flow of electric current. Among the various types of resistors, metal film resistors stand out due to their unique properties and versatility. These components are widely used in a range of applications, from consumer electronics to aerospace systems. This article aims to explore the main application directions of metal film resistors, highlighting their characteristics, advantages, and the challenges they face in the ever-evolving technological landscape.

II. Characteristics of Metal Film Resistors

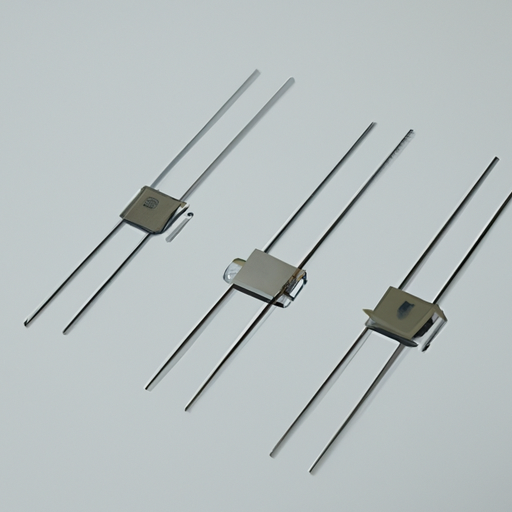

A. Composition and Manufacturing Process

Metal film resistors are made by depositing a thin layer of metal onto a ceramic substrate. The metal layer is then etched to create a precise resistance value. This manufacturing process allows for high precision and consistency, making metal film resistors a preferred choice in applications where accuracy is paramount.

B. Key Properties

1. **Tolerance and Precision**: Metal film resistors typically offer tolerances as low as 0.1%, making them ideal for applications requiring high accuracy.

2. **Temperature Coefficient**: These resistors have a low temperature coefficient, meaning their resistance value changes very little with temperature fluctuations. This stability is crucial in precision applications.

3. **Stability and Reliability**: Metal film resistors exhibit excellent long-term stability, ensuring that their performance remains consistent over time.

C. Comparison with Other Types of Resistors

1. **Carbon Film Resistors**: While carbon film resistors are cost-effective, they generally have higher noise levels and lower precision compared to metal film resistors.

2. **Wirewound Resistors**: Wirewound resistors can handle higher power ratings but are bulkier and less suitable for applications requiring high precision.

3. **Thick Film Resistors**: Thick film resistors are often used in low-cost applications but do not match the precision and stability of metal film resistors.

III. Main Application Directions

A. Consumer Electronics

Metal film resistors are widely used in consumer electronics, where precision and reliability are essential.

1. **Audio Equipment**: In high-fidelity audio systems, metal film resistors help maintain signal integrity, ensuring clear sound reproduction.

2. **Home Appliances**: These resistors are found in various home appliances, from washing machines to microwaves, where they contribute to efficient operation.

3. **Mobile Devices**: In smartphones and tablets, metal film resistors are used in power management circuits, enhancing battery life and performance.

B. Industrial Applications

In industrial settings, metal film resistors are crucial for automation and control systems.

1. **Automation and Control Systems**: They are used in programmable logic controllers (PLCs) and other control devices, ensuring accurate signal processing.

2. **Measurement and Testing Equipment**: Precision measurement devices, such as oscilloscopes and multimeters, rely on metal film resistors for accurate readings.

3. **Robotics**: In robotic systems, these resistors help maintain precise control over motors and sensors, enhancing overall performance.

C. Telecommunications

The telecommunications industry benefits significantly from the use of metal film resistors.

1. **Signal Processing**: In signal processing applications, these resistors help maintain signal integrity, reducing distortion and noise.

2. **Network Equipment**: Metal film resistors are used in routers and switches, ensuring reliable data transmission.

3. **RF Applications**: In radio frequency applications, they provide the necessary precision for tuning and filtering circuits.

D. Medical Devices

In the medical field, the reliability and precision of metal film resistors are paramount.

1. **Diagnostic Equipment**: Devices such as MRI machines and ultrasound equipment rely on these resistors for accurate measurements.

2. **Monitoring Devices**: In patient monitoring systems, metal film resistors ensure that vital signs are measured accurately.

3. **Therapeutic Equipment**: Equipment used for therapies, such as electrical stimulation devices, also utilize metal film resistors for precise control.

E. Automotive Industry

The automotive industry has increasingly adopted metal film resistors in various applications.

1. **Engine Control Units (ECUs)**: These resistors are used in ECUs to ensure accurate sensor readings and control engine performance.

2. **Safety Systems**: In safety systems, such as airbags and anti-lock braking systems, metal film resistors contribute to reliable operation.

3. **Infotainment Systems**: Metal film resistors are also found in infotainment systems, ensuring high-quality audio and video performance.

F. Aerospace and Defense

In aerospace and defense applications, the reliability of metal film resistors is critical.

1. **Avionics**: Metal film resistors are used in avionics systems, where precision and reliability are essential for navigation and communication.

2. **Navigation Systems**: These resistors help maintain accurate readings in GPS and other navigation systems.

3. **Military Equipment**: In military applications, metal film resistors are used in various devices, from communication systems to weaponry, where performance cannot be compromised.

IV. Advantages of Metal Film Resistors in Various Applications

Metal film resistors offer several advantages that make them suitable for a wide range of applications:

A. High Precision and Accuracy

With tolerances as low as 0.1%, metal film resistors provide the high precision required in critical applications, ensuring that circuits function as intended.

B. Low Noise Characteristics

These resistors exhibit low noise levels, making them ideal for audio and signal processing applications where clarity is essential.

C. Enhanced Stability Over Time

Metal film resistors maintain their performance over time, reducing the need for frequent replacements and ensuring long-term reliability.

D. Wide Range of Resistance Values

Available in a broad range of resistance values, metal film resistors can be tailored to meet specific application requirements.

E. Compact Size and Design Flexibility

Their small size allows for greater design flexibility, making them suitable for compact electronic devices.

V. Challenges and Limitations

Despite their advantages, metal film resistors face several challenges:

A. Cost Considerations

Metal film resistors are generally more expensive than other types of resistors, which can be a limiting factor in cost-sensitive applications.

B. Power Rating Limitations

While they are suitable for many applications, metal film resistors have lower power ratings compared to wirewound resistors, limiting their use in high-power applications.

C. Environmental Sensitivity

Metal film resistors can be sensitive to environmental factors, such as humidity and temperature, which may affect their performance.

D. Competition from Alternative Technologies

The rise of alternative technologies, such as digital resistors and programmable devices, poses a challenge to the traditional resistor market.

VI. Future Trends and Innovations

The future of metal film resistors looks promising, with several trends and innovations on the horizon:

A. Advancements in Manufacturing Techniques

New manufacturing techniques are being developed to enhance the precision and reduce the cost of metal film resistors.

B. Integration with Smart Technologies

As the Internet of Things (IoT) continues to grow, metal film resistors are being integrated into smart devices, enhancing their functionality.

C. Development of Specialty Resistors

There is a growing demand for specialty resistors tailored for specific applications, driving innovation in the metal film resistor market.

D. Sustainability and Eco-Friendly Practices

Manufacturers are increasingly focusing on sustainable practices, including the use of eco-friendly materials and processes in the production of metal film resistors.

VII. Conclusion

Metal film resistors play a vital role in modern electronics, offering high precision, stability, and reliability across various applications. From consumer electronics to aerospace systems, their versatility makes them indispensable in many fields. While challenges such as cost and competition from alternative technologies exist, ongoing innovations and advancements in manufacturing techniques promise a bright future for metal film resistors. As technology continues to evolve, these components will remain at the forefront of electronic design, ensuring that they meet the demands of an increasingly complex world.

VIII. References

- Academic Journals

- Industry Reports

- Manufacturer Specifications

- Relevant Books and Articles

This comprehensive exploration of metal film resistors highlights their significance in various applications, their advantages, and the challenges they face, providing a clear understanding of their role in the electronics industry.