CORE_COMPETENCE

Product_Leaders

index_more

index_more_content

info_item01

info_item_content01

info_item02

info_item_content02

info_item03

info_item_content03

info_item04

info_item_content04

NEWS

NEWS

What is the market prospect of aluminum electrolytic capacitors?

What is the Market Prospect of Aluminum Electrolytic Capacitors?

I. Introduction

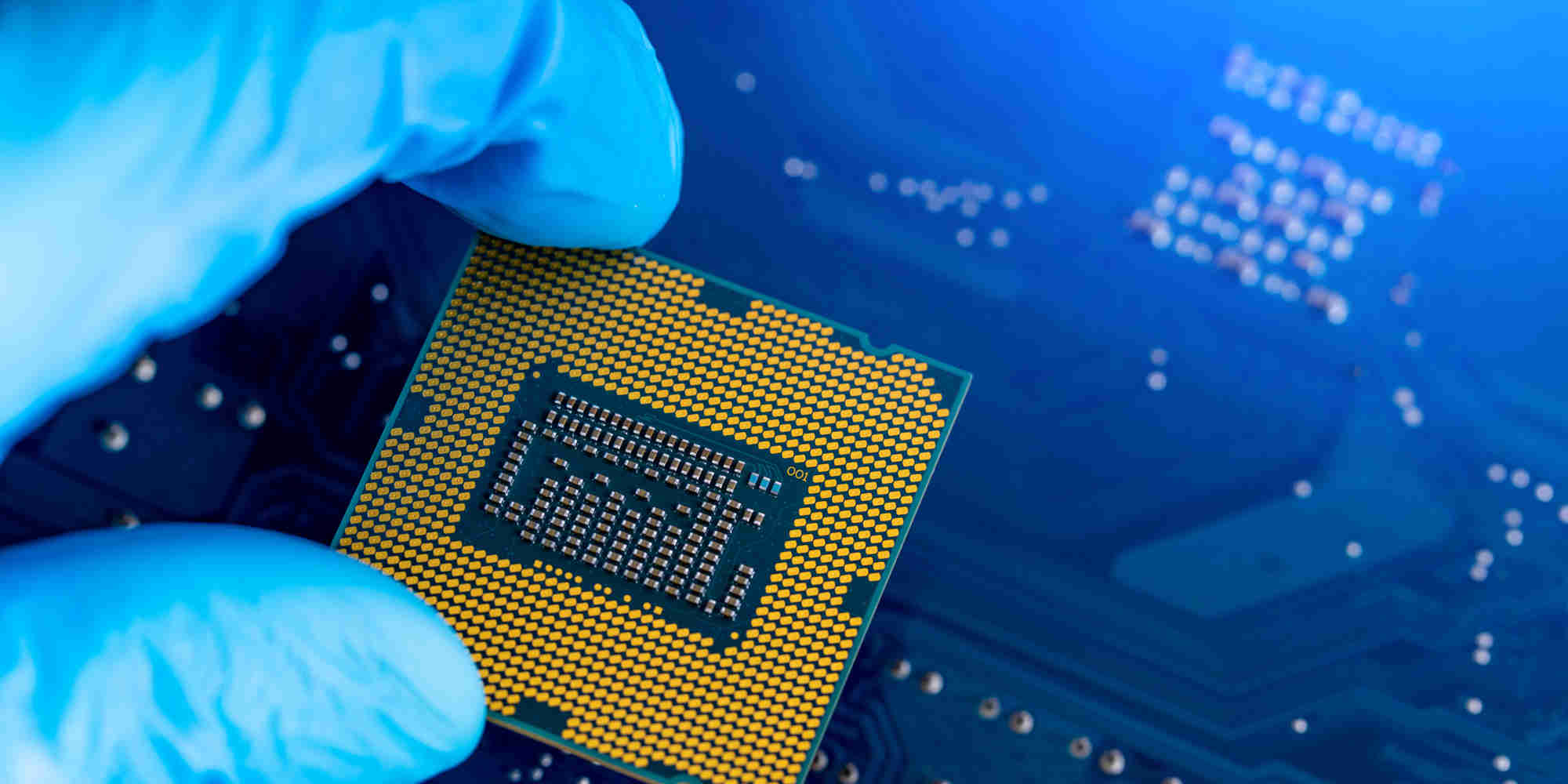

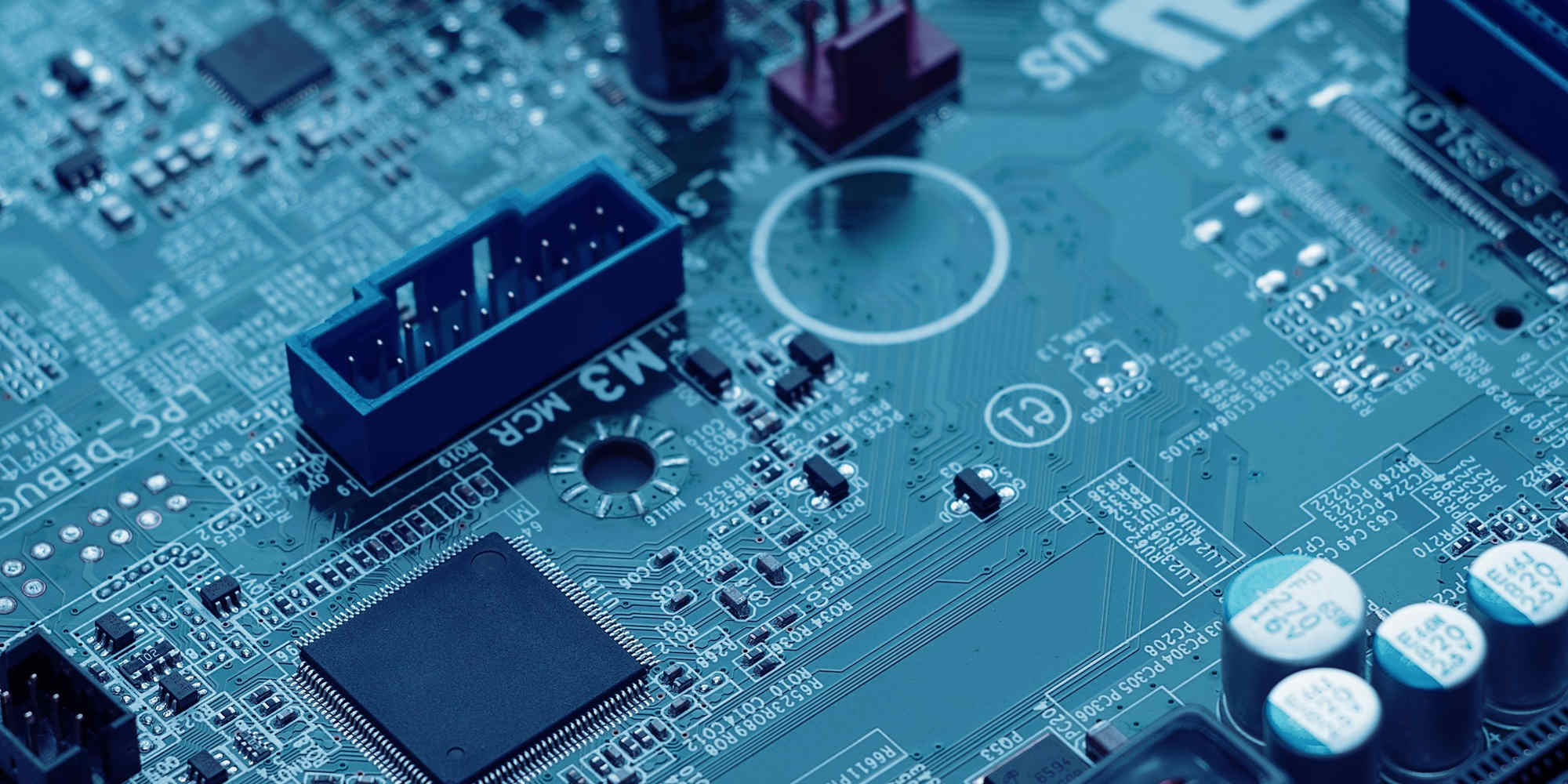

Aluminum electrolytic capacitors are essential components in electronic circuits, known for their ability to store and release electrical energy efficiently. These capacitors are widely used in various applications, from consumer electronics to industrial machinery, due to their high capacitance values and relatively low cost. As technology continues to evolve, the market landscape for aluminum electrolytic capacitors is also changing, driven by advancements in technology, shifts in consumer demand, and emerging applications. This blog post explores the market prospects of aluminum electrolytic capacitors, examining historical context, current trends, competitive dynamics, challenges, and future opportunities.

II. Historical Context

The development of aluminum electrolytic capacitors dates back to the early 20th century, with significant advancements occurring throughout the decades. Initially, these capacitors were bulky and limited in their applications. However, as technology progressed, the design and manufacturing processes improved, leading to smaller, more efficient capacitors. Key milestones in the market include the introduction of new materials and manufacturing techniques, which have enhanced the performance and reliability of aluminum electrolytic capacitors. Over the years, these components have become integral to various electronic devices, paving the way for their widespread adoption in modern technology.

III. Current Market Trends

A. Global Demand and Supply Dynamics

The global market for aluminum electrolytic capacitors is experiencing robust growth, driven by increasing demand across multiple sectors. According to recent market research, the demand for these capacitors is expected to rise significantly in the coming years, fueled by the proliferation of electronic devices and the growing emphasis on energy efficiency.

B. Key Industries Driving Demand

1. **Consumer Electronics**: The consumer electronics sector is one of the largest markets for aluminum electrolytic capacitors. With the continuous launch of new products such as smartphones, tablets, and laptops, the demand for reliable and efficient capacitors is on the rise.

2. **Automotive**: The automotive industry is increasingly adopting aluminum electrolytic capacitors, particularly with the shift towards electric vehicles (EVs). These capacitors play a crucial role in power management systems, battery management, and various electronic control units.

3. **Industrial Applications**: In industrial settings, aluminum electrolytic capacitors are used in machinery, automation systems, and power supplies. The growing trend of industrial automation and the Internet of Things (IoT) is further driving demand in this sector.

4. **Renewable Energy**: The renewable energy sector, particularly solar and wind energy, is also contributing to the demand for aluminum electrolytic capacitors. These capacitors are essential for energy storage systems and power conditioning applications.

C. Technological Advancements

1. **Miniaturization**: One of the most significant trends in the aluminum electrolytic capacitor market is miniaturization. As electronic devices become smaller and more compact, the demand for smaller capacitors with high capacitance values is increasing.

2. **Enhanced Performance Characteristics**: Manufacturers are focusing on improving the performance characteristics of aluminum electrolytic capacitors, such as increasing their voltage ratings, reducing equivalent series resistance (ESR), and enhancing their lifespan.

3. **Eco-Friendly Alternatives**: With growing environmental concerns, there is a push for eco-friendly alternatives in capacitor technology. Manufacturers are exploring the use of sustainable materials and production processes to reduce the environmental impact of aluminum electrolytic capacitors.

IV. Competitive Landscape

A. Major Players in the Aluminum Electrolytic Capacitor Market

The aluminum electrolytic capacitor market is characterized by the presence of several key players. Leading manufacturers include companies such as Panasonic, Nichicon, Rubycon, and KEMET. These companies dominate the market due to their extensive product portfolios, strong brand recognition, and commitment to innovation.

B. Strategies Employed by Key Players

1. **Product Innovation**: Major players are investing heavily in research and development to create innovative products that meet the evolving needs of customers. This includes developing capacitors with higher capacitance values, improved reliability, and enhanced performance.

2. **Mergers and Acquisitions**: To strengthen their market position, companies are engaging in mergers and acquisitions. This strategy allows them to expand their product offerings, enter new markets, and leverage synergies.

3. **Geographic Expansion**: Many manufacturers are focusing on expanding their presence in emerging markets, where the demand for electronic devices is rapidly increasing. This geographic expansion strategy helps them tap into new customer bases and drive growth.

V. Challenges Facing the Market

Despite the positive outlook for aluminum electrolytic capacitors, the market faces several challenges:

A. Competition from Alternative Capacitor Technologies

The rise of alternative capacitor technologies, such as ceramic and film capacitors, poses a significant challenge to the aluminum electrolytic capacitor market. These alternatives often offer superior performance characteristics, leading to increased competition.

B. Supply Chain Disruptions

Recent global events have highlighted vulnerabilities in supply chains, leading to disruptions in the availability of raw materials required for capacitor manufacturing. These disruptions can impact production schedules and increase costs.

C. Regulatory Challenges and Environmental Concerns

As environmental regulations become more stringent, manufacturers must navigate complex compliance requirements. Additionally, there is growing pressure to develop eco-friendly products, which can pose challenges for traditional manufacturing processes.

D. Price Volatility of Raw Materials

The price volatility of raw materials, such as aluminum and electrolytic solutions, can significantly impact the profitability of manufacturers. Fluctuations in raw material prices can lead to increased production costs and affect pricing strategies.

VI. Future Market Prospects

A. Growth Forecasts and Market Size Projections

The future of the aluminum electrolytic capacitor market looks promising, with growth forecasts indicating a steady increase in market size. Analysts predict that the market will continue to expand, driven by the increasing demand for electronic devices and the growing emphasis on energy efficiency.

B. Emerging Applications and Technologies

1. **Electric Vehicles (EVs)**: The shift towards electric vehicles presents a significant opportunity for aluminum electrolytic capacitors. As the automotive industry embraces electrification, the demand for capacitors in EV applications is expected to rise.

2. **Internet of Things (IoT)**: The proliferation of IoT devices is creating new opportunities for aluminum electrolytic capacitors. These capacitors are essential for power management and energy storage in connected devices.

3. **Smart Grids**: The development of smart grids is another emerging application for aluminum electrolytic capacitors. These capacitors play a crucial role in energy storage and power conditioning, supporting the transition to more efficient energy systems.

C. Potential for Market Expansion in Developing Regions

Developing regions, particularly in Asia-Pacific and Latin America, present significant growth opportunities for the aluminum electrolytic capacitor market. As these regions experience rapid industrialization and urbanization, the demand for electronic devices and components is expected to surge.

VII. Conclusion

In summary, the market prospects for aluminum electrolytic capacitors are bright, driven by historical advancements, current trends, and future opportunities. While challenges such as competition from alternative technologies and supply chain disruptions exist, the overall outlook remains positive. Stakeholders in the industry should focus on innovation, sustainability, and geographic expansion to capitalize on the growing demand for aluminum electrolytic capacitors. As technology continues to evolve, these capacitors will play a vital role in shaping the future of electronic devices and systems.

VIII. References

1. Market Research Reports on Aluminum Electrolytic Capacitors

2. Industry Analysis Reports from Leading Market Research Firms

3. Academic Journals on Capacitor Technology and Applications

4. News Articles on Trends in Consumer Electronics and Automotive Industries

This blog post provides a comprehensive overview of the market prospects for aluminum electrolytic capacitors, highlighting their importance in various industries and the factors influencing their growth. As the demand for electronic devices continues to rise, aluminum electrolytic capacitors will remain a critical component in the electronics landscape.

2024-12-11

What are the popular models of capacitor formula?

What are the Popular Models of Capacitor Formula?

I. Introduction

Capacitors are fundamental components in electrical circuits, playing a crucial role in storing and releasing electrical energy. They are widely used in various applications, from simple timing circuits to complex power electronics. Understanding the different models of capacitor formulas is essential for engineers and technicians, as it allows them to predict how capacitors will behave in different scenarios. This article will explore the basic principles of capacitors, popular models of capacitor formulas, and their practical applications.

II. Basic Principles of Capacitors

A. Explanation of Capacitance

Capacitance is the ability of a capacitor to store electrical charge. It is defined as the ratio of the electric charge (Q) stored on one plate of the capacitor to the voltage (V) across the plates. The unit of capacitance is the Farad (F), which is a relatively large unit. In practice, capacitors are often measured in microfarads (µF), nanofarads (nF), or picofarads (pF).

Several factors affect capacitance:

1. **Area of the Plates**: The larger the surface area of the capacitor plates, the greater the capacitance. This is because a larger area can store more charge.

2. **Distance Between Plates**: The closer the plates are to each other, the higher the capacitance. Reducing the distance increases the electric field strength, allowing more charge to be stored.

3. **Dielectric Material**: The material between the plates, known as the dielectric, influences capacitance. Different materials have different dielectric constants, which affect the capacitor's ability to store charge.

B. The Capacitor Formula

The basic formula for capacitance is given by:

\[ C = \frac{Q}{V} \]

Where:

- \( C \) = Capacitance (in Farads)

- \( Q \) = Charge (in Coulombs)

- \( V \) = Voltage (in Volts)

This formula provides a fundamental understanding of how capacitors operate, but it does not account for the complexities of real-world applications.

III. Popular Models of Capacitor Formula

A. Ideal Capacitor Model

The ideal capacitor model assumes that the capacitor behaves perfectly according to the basic formula. In this model, the capacitor has no resistance or inductance, and it can charge and discharge instantaneously. This model is useful for theoretical analysis and simplifies calculations in circuit design.

However, real capacitors do not behave perfectly, and the ideal model is often insufficient for practical applications.

B. Real Capacitor Model

Real capacitors exhibit non-ideal behavior due to various factors, including Equivalent Series Resistance (ESR) and Equivalent Series Inductance (ESL).

1. **Equivalent Series Resistance (ESR)**: This represents the resistive losses in the capacitor, which can lead to heat generation and reduced efficiency. ESR is particularly important in high-frequency applications where losses can significantly impact performance.

2. **Equivalent Series Inductance (ESL)**: This accounts for the inductive effects of the capacitor's leads and construction. ESL can affect the capacitor's performance at high frequencies, leading to resonance and reduced effectiveness.

The real capacitor model is essential for accurately predicting performance in circuits, especially in applications like power supplies and RF circuits.

C. Dielectric Models

Capacitors can be made with various dielectric materials, each influencing capacitance differently. Common types of dielectrics include:

1. **Ceramic**: Known for their stability and reliability, ceramic capacitors are widely used in high-frequency applications.

2. **Electrolytic**: These capacitors have high capacitance values and are often used in power supply applications. However, they are polarized and can fail if connected incorrectly.

3. **Film**: Film capacitors are known for their low ESR and ESL, making them suitable for audio and precision applications.

The dielectric properties can be incorporated into the capacitance formula, leading to variations based on the type of dielectric used. For example, the capacitance of a parallel plate capacitor can be expressed as:

\[ C = \frac{\varepsilon_r \cdot \varepsilon_0 \cdot A}{d} \]

Where:

- \( \varepsilon_r \) = Relative permittivity (dielectric constant) of the material

- \( \varepsilon_0 \) = Permittivity of free space (approximately \( 8.854 \times 10^{-12} \, F/m \))

- \( A \) = Area of the plates

- \( d \) = Distance between the plates

D. Temperature and Frequency Effects

Capacitance can also be affected by temperature and frequency.

1. **Temperature Effects**: As temperature changes, the dielectric properties of the material can change, leading to variations in capacitance. For example, some dielectrics may exhibit increased capacitance at higher temperatures, while others may decrease.

2. **Frequency Response**: Capacitors do not behave the same way at all frequencies. At high frequencies, the effects of ESL and ESR become more pronounced, leading to a decrease in effective capacitance. Formulas that account for frequency response are essential for designing circuits that operate over a range of frequencies.

IV. Advanced Capacitor Models

A. Nonlinear Capacitor Models

In some applications, capacitors exhibit nonlinear behavior, meaning their capacitance changes with the applied voltage. This is particularly relevant in varactors, which are used in tuning circuits. The mathematical representation of nonlinear capacitors can be complex, often requiring specialized models to accurately predict their behavior.

B. Time-Variant Capacitor Models

Time-variant capacitors change their capacitance over time, which can be crucial in dynamic circuits. These models are essential for applications like signal processing and communication systems, where the capacitance may need to adapt to changing conditions.

C. Multi-Layer Capacitor Models

Multi-layer capacitors consist of several layers of dielectric material and conductive plates, allowing for higher capacitance in a smaller volume. The capacitance of these configurations can be calculated using formulas that consider the arrangement and properties of each layer.

V. Practical Applications of Capacitor Models

Capacitor models are vital in various practical applications:

A. Use in Filtering Applications

Capacitors are commonly used in filtering applications to smooth out voltage fluctuations in power supplies. By understanding the capacitor models, engineers can design effective filters that meet specific performance criteria.

B. Role in Energy Storage Systems

Capacitors play a crucial role in energy storage systems, such as in electric vehicles and renewable energy systems. Accurate modeling of capacitors allows for efficient energy management and system design.

C. Importance in Timing Circuits

In timing circuits, capacitors are used to create delays and control timing intervals. Understanding the behavior of capacitors under different conditions is essential for designing reliable timing circuits.

D. Applications in Power Electronics

Capacitors are integral to power electronics, where they are used for energy storage, filtering, and voltage regulation. Accurate models help engineers optimize circuit performance and efficiency.

VI. Conclusion

Understanding the various models of capacitor formulas is essential for engineers and technicians working in electronics and electrical engineering. From the basic principles of capacitance to advanced models that account for non-ideal behavior, these concepts are crucial for designing effective circuits. As technology continues to evolve, so too will the models and applications of capacitors, making it an exciting field for future exploration.

VII. References

For further study on capacitor theory and applications, consider the following resources:

1. "Capacitors: Principles and Applications" by John Smith

2. "Fundamentals of Electric Circuits" by Charles Alexander and Matthew Sadiku

3. Academic papers on capacitor modeling and performance in IEEE journals

By delving into these resources, readers can deepen their understanding of capacitors and their critical role in modern electronics.

2024-12-10

How do supercapacitors work?

How Do Supercapacitors Work?

I. Introduction

In an age where energy efficiency and storage are paramount, supercapacitors have emerged as a vital technology in the realm of energy storage. Defined as electrochemical capacitors that can store and release energy rapidly, supercapacitors bridge the gap between traditional capacitors and batteries. Their unique properties make them essential in various applications, from consumer electronics to renewable energy systems. This article aims to explore the workings of supercapacitors, their advantages and limitations, and their potential future in energy storage technology.

II. Historical Background

The journey of supercapacitors began in the 1950s, with the development of the first double-layer capacitors. These early devices laid the groundwork for what would evolve into modern supercapacitors. Unlike traditional capacitors, which store energy electrostatically, supercapacitors utilize electrochemical processes, allowing for greater energy storage capabilities.

Over the decades, advancements in materials and technology have significantly improved supercapacitor performance. Early models relied on simple carbon-based materials, but the introduction of advanced materials like graphene and carbon nanotubes has revolutionized the field. This evolution has led to supercapacitors that can store more energy, charge faster, and last longer than their predecessors.

III. Basic Principles of Supercapacitors

A. Definition and Function

Supercapacitors function by storing energy through two primary mechanisms: electrostatic charge storage and Faradaic charge storage. The former occurs in electric double-layer capacitors (EDLCs), where energy is stored at the interface between the electrode and electrolyte. In contrast, pseudocapacitors utilize Faradaic reactions, where charge is stored through reversible electrochemical reactions.

B. Key Components

Supercapacitors consist of three main components:

1. **Electrodes**: These are typically made from high-surface-area materials that facilitate charge storage. The choice of electrode material significantly impacts the performance of the supercapacitor.

2. **Electrolytes**: The electrolyte serves as the medium through which ions move between the electrodes. It can be aqueous or non-aqueous, each with its own advantages and disadvantages.

3. **Separator**: This component prevents direct contact between the electrodes while allowing ionic movement, ensuring the safe operation of the supercapacitor.

C. Types of Supercapacitors

Supercapacitors can be categorized into three main types:

1. **Electric Double-Layer Capacitors (EDLCs)**: These rely on electrostatic charge storage and are known for their high power density and long cycle life.

2. **Pseudocapacitors**: These utilize Faradaic charge storage mechanisms, allowing for higher energy density compared to EDLCs.

3. **Hybrid Capacitors**: Combining features of both EDLCs and batteries, hybrid capacitors offer a balance between energy and power density.

IV. How Supercapacitors Work

A. Charge Storage Mechanisms

The charge storage mechanisms in supercapacitors are fundamental to their operation. In EDLCs, energy is stored through the electrostatic separation of charges at the electrode-electrolyte interface. This process is highly efficient, allowing for rapid charge and discharge cycles.

In pseudocapacitors, energy storage occurs through Faradaic reactions, where ions from the electrolyte participate in reversible electrochemical reactions at the electrode surface. This mechanism enables higher energy storage but typically results in slower charge and discharge rates compared to EDLCs.

B. Role of Surface Area and Porosity

The performance of supercapacitors is heavily influenced by the surface area and porosity of the electrode materials. A larger surface area allows for more charge storage sites, while increased porosity enhances the accessibility of the electrolyte ions to the electrode surface. Common materials used for electrodes include activated carbon, which offers a high surface area, and advanced materials like graphene, known for its exceptional conductivity and mechanical strength.

C. Electrolyte Types and Their Impact on Performance

The choice of electrolyte plays a crucial role in the performance of supercapacitors. Aqueous electrolytes, while safe and cost-effective, typically have lower voltage limits compared to non-aqueous electrolytes. Non-aqueous electrolytes can provide higher voltage and energy density but may come with safety concerns and higher costs. Ionic conductivity, which measures how easily ions move through the electrolyte, is also a critical factor influencing the overall performance of supercapacitors.

V. Advantages of Supercapacitors

Supercapacitors offer several advantages that make them attractive for various applications:

A. High Power Density

One of the most significant benefits of supercapacitors is their high power density, allowing them to deliver quick bursts of energy. This characteristic is particularly useful in applications requiring rapid energy discharge, such as in regenerative braking systems in electric vehicles.

B. Rapid Charge and Discharge Capabilities

Supercapacitors can be charged and discharged much faster than traditional batteries. This rapid cycling capability makes them ideal for applications where quick energy delivery is essential, such as in power backup systems and energy harvesting devices.

C. Long Cycle Life and Durability

Supercapacitors can endure hundreds of thousands to millions of charge and discharge cycles without significant degradation. This longevity makes them a cost-effective solution for applications requiring frequent cycling.

D. Environmental Benefits and Recyclability

Supercapacitors are generally more environmentally friendly than traditional batteries. They often use less toxic materials and can be recycled more easily, contributing to a more sustainable energy storage solution.

VI. Limitations of Supercapacitors

Despite their advantages, supercapacitors also have limitations that must be considered:

A. Lower Energy Density Compared to Batteries

While supercapacitors excel in power density, they fall short in energy density compared to batteries. This means that while they can deliver energy quickly, they cannot store as much energy as batteries, making them less suitable for long-term energy storage.

B. Voltage Limitations and Balancing Issues

Supercapacitors have voltage limitations that can restrict their use in certain applications. Additionally, when used in series configurations, balancing issues can arise, necessitating additional circuitry to ensure even charge distribution.

C. Cost Considerations and Material Availability

The cost of advanced materials used in supercapacitors, such as graphene, can be a barrier to widespread adoption. Additionally, the availability of these materials may impact the scalability of supercapacitor technology.

VII. Applications of Supercapacitors

Supercapacitors find applications across various sectors:

A. Consumer Electronics

In consumer electronics, supercapacitors are used for energy storage in devices like smartphones and tablets, providing quick bursts of power for features like camera flashes and screen activation.

B. Renewable Energy Systems

Supercapacitors play a crucial role in renewable energy systems, such as solar and wind power, by storing excess energy generated during peak production times and releasing it when demand is high.

C. Electric Vehicles and Transportation

In electric vehicles, supercapacitors are used in conjunction with batteries to enhance performance. They provide rapid acceleration and regenerative braking capabilities, improving overall efficiency.

D. Industrial Applications

Industries utilize supercapacitors for applications requiring high power output, such as in cranes, forklifts, and other heavy machinery, where quick energy delivery is essential.

VIII. Future Trends and Innovations

The future of supercapacitors looks promising, with ongoing research and development focused on improving materials and performance. Innovations in nanotechnology and advanced materials are expected to enhance energy density and reduce costs.

A. Research and Development in Materials

Researchers are exploring new materials, such as metal-organic frameworks (MOFs) and conductive polymers, to improve the performance of supercapacitors. These materials may offer higher energy densities and better cycling stability.

B. Integration with Other Energy Storage Technologies

The integration of supercapacitors with other energy storage technologies, such as lithium-ion batteries, is gaining traction. This hybrid approach can leverage the strengths of both technologies, providing a more versatile energy storage solution.

C. Potential for New Applications and Markets

As technology advances, new applications for supercapacitors are likely to emerge. From grid energy storage to wearable electronics, the potential markets for supercapacitors are vast and varied.

IX. Conclusion

In summary, supercapacitors represent a significant advancement in energy storage technology, offering unique advantages such as high power density, rapid charge and discharge capabilities, and long cycle life. While they have limitations, their applications across various sectors demonstrate their importance in modern technology. As research and innovation continue to evolve, supercapacitors are poised to play a crucial role in the future of energy storage, contributing to a more sustainable and efficient energy landscape. Continued investment in this field will be essential to unlocking the full potential of supercapacitors and addressing the growing energy demands of our world.

2024-12-09