Popular Models of Capacitor Brands

I. Introduction

Capacitors are fundamental components in electronic circuits, serving as energy storage devices that can release energy when needed. They play a crucial role in various applications, from power supply smoothing to signal coupling and filtering. The capacitor market is diverse, with numerous brands offering a wide range of products tailored to different needs. Understanding the popular models from leading capacitor brands can help engineers and hobbyists make informed decisions when selecting components for their projects.

II. Types of Capacitors

Before diving into specific brands, it’s essential to understand the different types of capacitors available in the market:

A. Electrolytic Capacitors

Electrolytic capacitors are polarized components that typically offer high capacitance values in a compact size. They are widely used in power supply circuits, audio equipment, and energy storage applications.

B. Ceramic Capacitors

Ceramic capacitors are non-polarized and known for their stability and reliability. They are commonly used in high-frequency applications, decoupling, and filtering.

C. Film Capacitors

Film capacitors are made from thin plastic films and are known for their low ESR and high voltage ratings. They are often used in audio applications, power electronics, and timing circuits.

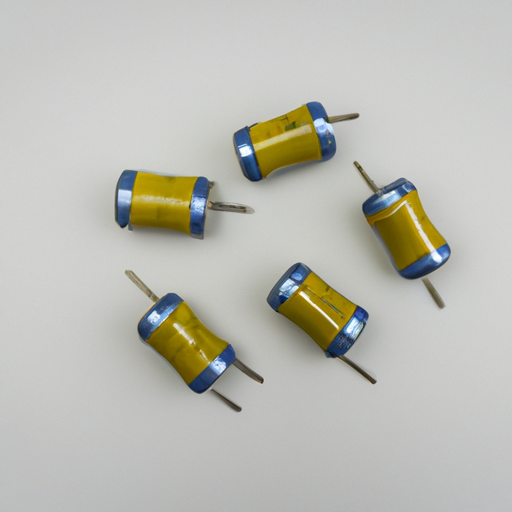

D. Tantalum Capacitors

Tantalum capacitors are known for their high capacitance in small sizes and stable electrical characteristics. They are often used in applications requiring reliability, such as medical devices and aerospace.

E. Supercapacitors

Supercapacitors, or ultracapacitors, are energy storage devices that bridge the gap between traditional capacitors and batteries. They are used in applications requiring rapid charge and discharge cycles, such as energy harvesting and backup power.

III. Leading Capacitor Brands

The capacitor market is populated by several key players, each with its own strengths and popular models. Here’s an overview of some of the leading brands:

1. Panasonic

Panasonic has a long-standing reputation in the electronics industry, known for its high-quality capacitors.

Popular Models:

EEU-FR Series (Electrolytic): This series is known for its long life and high reliability, making it suitable for power supply applications.

ECQ Series (Film): These film capacitors are recognized for their excellent performance in audio and high-frequency applications.

Applications and Performance: Panasonic capacitors are widely used in consumer electronics, automotive, and industrial applications, providing stable performance and longevity.

2. Nichicon

Nichicon is another prominent name in the capacitor industry, known for its innovation and quality.

Popular Models:

UHE Series (Electrolytic): This series features low ESR and high ripple current capabilities, ideal for power supply circuits.

PLF Series (Low-ESR): Designed for high-performance applications, these capacitors are perfect for audio and power electronics.

Applications and Performance: Nichicon capacitors are commonly found in audio equipment, power supplies, and industrial applications, offering reliability and efficiency.

3. KEMET

KEMET is known for its diverse range of capacitors and commitment to innovation.

Popular Models:

T491 Series (Tantalum): This series is recognized for its high capacitance and reliability, suitable for compact designs.

C4AE Series (Ceramic): These capacitors offer excellent performance in high-frequency applications.

Applications and Performance: KEMET capacitors are used in telecommunications, automotive, and consumer electronics, providing high performance and durability.

4. Vishay

Vishay is a global leader in discrete semiconductors and passive components, including capacitors.

Popular Models:

1812 Series (Ceramic): This series is known for its reliability and stability in various applications.

193 Series (Film): These film capacitors are designed for high-frequency applications, providing low losses and high performance.

Applications and Performance: Vishay capacitors are widely used in industrial, automotive, and consumer electronics, ensuring high reliability and performance.

5. Rubycon

Rubycon is a well-respected brand in the capacitor market, known for its high-quality electrolytic capacitors.

Popular Models:

ZLJ Series (Electrolytic): This series is designed for high ripple current and long life, making it suitable for power supply applications.

YXF Series (Low-ESR): These capacitors are ideal for high-performance applications, providing low ESR and high reliability.

Applications and Performance: Rubycon capacitors are commonly used in audio equipment, power supplies, and industrial applications, offering excellent performance and longevity.

6. Murata

Murata is a leading manufacturer of ceramic capacitors, known for its innovation and quality.

Popular Models:

GRM Series (Ceramic): This series is recognized for its compact size and high capacitance, suitable for various applications.

DMT Series (Multilayer): These capacitors are designed for high-frequency applications, providing excellent performance.

Applications and Performance: Murata capacitors are widely used in telecommunications, automotive, and consumer electronics, ensuring high reliability and performance.

7. WIMA

WIMA specializes in film capacitors, known for their high quality and performance.

Popular Models:

MKS Series (Film): This series is known for its reliability and stability in various applications.

FKP Series (Film): These capacitors are designed for high-frequency applications, providing low losses and high performance.

Applications and Performance: WIMA capacitors are commonly used in audio equipment, power electronics, and industrial applications, ensuring high reliability and performance.

IV. Factors to Consider When Choosing Capacitors

When selecting capacitors for specific applications, several factors should be considered:

A. Voltage Rating

The voltage rating indicates the maximum voltage the capacitor can handle. It’s essential to choose a capacitor with a voltage rating higher than the maximum voltage in the circuit.

B. Capacitance Value

The capacitance value determines the amount of charge the capacitor can store. It’s crucial to select a capacitance value that meets the requirements of the application.

C. ESR (Equivalent Series Resistance)

ESR affects the performance of capacitors, especially in high-frequency applications. Lower ESR values are generally preferred for better performance.

D. Temperature Coefficient

The temperature coefficient indicates how the capacitance value changes with temperature. It’s essential to choose capacitors with suitable temperature coefficients for the application.

E. Size and Form Factor

The physical size and form factor of the capacitor can impact the design of the circuit. It’s important to select capacitors that fit within the available space in the design.

V. Conclusion

In summary, understanding the popular capacitor brands and their models is crucial for selecting the right components for electronic applications. Brands like Panasonic, Nichicon, KEMET, Vishay, Rubycon, Murata, and WIMA offer a wide range of capacitors tailored to various needs. When choosing capacitors, it’s essential to consider factors such as voltage rating, capacitance value, ESR, temperature coefficient, and size. As technology continues to evolve, the capacitor market will likely see advancements in performance and new product offerings, making it an exciting field for engineers and hobbyists alike.

VI. References

For further reading on capacitors and their applications, consider exploring the following resources:

- Manufacturer datasheets and technical specifications

- Industry standards and guidelines for capacitors

- Electronics textbooks and online courses on circuit design and components

By staying informed about the latest developments in capacitor technology and brand offerings, you can make better decisions for your electronic projects.