What are the Main Application Directions of Resistor RT54?

I. Introduction

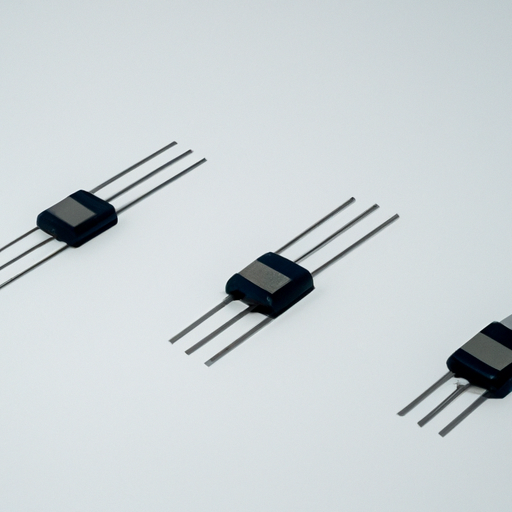

Resistors are fundamental components in electronic circuits, serving the essential function of controlling current flow. Among the various types of resistors available, the RT54 resistor stands out due to its unique specifications and versatility. This blog post aims to explore the main application directions of the RT54 resistor, highlighting its significance across different industries and technologies. We will delve into its technical specifications, key application areas, advantages, challenges, and future trends, providing a comprehensive understanding of this vital electronic component.

II. Understanding Resistor RT54

A. Technical Specifications

The RT54 resistor is characterized by specific technical specifications that make it suitable for a wide range of applications.

1. **Resistance Values**: The RT54 is available in a variety of resistance values, typically ranging from a few ohms to several megaohms. This range allows it to be used in different circuit configurations, catering to diverse electronic needs.

2. **Tolerance Levels**: Tolerance is a critical factor in resistor performance, indicating how much the actual resistance can vary from its stated value. The RT54 typically offers tolerance levels of ±1%, ±5%, or ±10%, ensuring reliability in precision applications.

3. **Power Rating**: The power rating of the RT54 resistor is another essential specification, usually ranging from 0.125W to 2W. This rating determines how much power the resistor can dissipate without overheating, making it crucial for applications where power management is vital.

B. Construction and Materials

The construction and materials used in the RT54 resistor contribute to its performance and reliability.

1. **Types of Materials Used**: The RT54 is commonly made from carbon film, metal film, or wire-wound materials. Each type has its advantages, with metal film resistors offering better stability and lower noise, while wire-wound resistors are preferred for high-power applications.

2. **Manufacturing Processes**: The manufacturing process of the RT54 involves precision techniques to ensure consistent quality and performance. Automated processes are often employed to maintain high standards and reduce production costs.

C. Comparison with Other Resistor Types

When compared to other resistor types, the RT54 offers a balance of performance, cost, and versatility. While some resistors may excel in specific applications, the RT54's broad range of resistance values and power ratings makes it a go-to choice for many electronic designs.

III. Key Application Areas of Resistor RT54

The RT54 resistor finds applications across various sectors, each leveraging its unique properties to enhance performance and reliability.

A. Consumer Electronics

1. **Role in Audio Devices**: In audio equipment, the RT54 is used to manage signal levels and prevent distortion, ensuring high-quality sound reproduction.

2. **Use in Video Equipment**: Video devices utilize the RT54 to regulate signal flow, contributing to clearer images and better overall performance.

3. **Applications in Home Appliances**: From washing machines to microwaves, the RT54 plays a crucial role in controlling electrical currents, enhancing the efficiency and safety of home appliances.

B. Industrial Applications

1. **Automation and Control Systems**: In industrial automation, the RT54 is essential for controlling sensors and actuators, ensuring precise operation in manufacturing processes.

2. **Power Management Systems**: The resistor is used in power management circuits to regulate voltage and current, contributing to energy efficiency in industrial settings.

3. **Instrumentation and Measurement Devices**: The RT54 is integral to measurement devices, providing accurate readings and ensuring reliable performance in various testing applications.

C. Automotive Industry

1. **Use in Electronic Control Units (ECUs)**: The RT54 is widely used in ECUs to manage various functions, from engine control to transmission systems, enhancing vehicle performance and efficiency.

2. **Applications in Safety Systems**: In automotive safety systems, the RT54 helps in the operation of airbags and anti-lock braking systems, ensuring timely and reliable responses in critical situations.

3. **Role in Infotainment Systems**: The resistor is also found in infotainment systems, where it helps manage audio signals and power distribution, contributing to an enhanced user experience.

D. Telecommunications

1. **Signal Processing Applications**: In telecommunications, the RT54 is used in signal processing circuits, ensuring clear and reliable communication.

2. **Use in Networking Equipment**: The resistor plays a vital role in networking devices, helping to manage data flow and maintain signal integrity.

3. **Role in RF Applications**: In radio frequency applications, the RT54 is essential for tuning circuits and impedance matching, ensuring optimal performance in wireless communication.

E. Medical Devices

1. **Applications in Diagnostic Equipment**: The RT54 is used in diagnostic devices, where it helps in signal conditioning and measurement accuracy, contributing to better patient outcomes.

2. **Use in Monitoring Devices**: In medical monitoring equipment, the resistor ensures reliable performance, providing accurate readings for vital signs and other critical parameters.

3. **Role in Therapeutic Equipment**: The RT54 is also found in therapeutic devices, where it helps manage electrical currents for treatments, ensuring patient safety and efficacy.

IV. Advantages of Using Resistor RT54

The RT54 resistor offers several advantages that make it a preferred choice in various applications.

A. Reliability and Stability

The RT54 is known for its reliability and stability, ensuring consistent performance over time. This is particularly important in critical applications where failure is not an option.

B. Versatility in Applications

With a wide range of resistance values and power ratings, the RT54 can be used in diverse applications, making it a versatile component in electronic design.

C. Cost-Effectiveness

The RT54 is competitively priced, providing an economical solution for manufacturers without compromising on quality or performance.

D. Availability and Ease of Sourcing

The RT54 is widely available from various suppliers, making it easy for manufacturers to source and integrate into their designs.

V. Challenges and Considerations

While the RT54 offers numerous advantages, there are also challenges and considerations to keep in mind.

A. Limitations in Specific Applications

The RT54 may not be suitable for high-frequency applications or extreme environmental conditions, where specialized resistors may be required.

B. Environmental Factors Affecting Performance

Temperature, humidity, and other environmental factors can impact the performance of the RT54, necessitating careful consideration during design.

C. Importance of Proper Selection and Integration

Selecting the right resistor for a specific application is crucial. Engineers must consider factors such as tolerance, power rating, and environmental conditions to ensure optimal performance.

VI. Future Trends and Innovations

As technology continues to evolve, the resistor industry is also witnessing advancements and innovations.

A. Advancements in Resistor Technology

New materials and manufacturing techniques are being developed to enhance resistor performance, including improved thermal stability and reduced noise levels.

B. Emerging Applications in New Fields

The rise of new technologies, such as electric vehicles and renewable energy systems, is creating new opportunities for the RT54 and similar resistors.

C. The Impact of Miniaturization and IoT

As devices become smaller and more interconnected, the demand for compact and efficient resistors like the RT54 is expected to grow, driving innovation in resistor design and manufacturing.

VII. Conclusion

In conclusion, the RT54 resistor is a vital component in modern electronics, with a wide range of applications across various industries. Its reliability, versatility, and cost-effectiveness make it a preferred choice for engineers and manufacturers alike. As technology continues to advance, the importance of resistors like the RT54 will only increase, paving the way for new innovations and applications in the future.

VIII. References

For further reading and in-depth understanding, consider exploring the following resources:

1. "Resistor Basics: Understanding Resistor Types and Applications" - Electronics Tutorials

2. "The Role of Resistors in Electronic Circuits" - IEEE Spectrum

3. "Advancements in Resistor Technology" - Journal of Electronic Materials

By understanding the significance of the RT54 resistor and its applications, we can appreciate the critical role it plays in shaping the future of technology.