What is the Mainstream Shanghai Resistor Production Process?

I. Introduction

Resistors are fundamental components in electronic circuits, serving the crucial role of controlling current flow and voltage levels. They are essential for the proper functioning of a wide array of devices, from simple household electronics to complex industrial machinery. As the global demand for electronic devices continues to rise, the importance of efficient and high-quality resistor production becomes increasingly evident. Shanghai, a major hub for electronics manufacturing, plays a significant role in the global resistor landscape. This article aims to explore the mainstream resistor production process in Shanghai, shedding light on the intricacies of this vital industry.

II. Understanding Resistors

A. Definition and Function of Resistors

A resistor is a passive electronic component that resists the flow of electric current, creating a voltage drop across its terminals. This property is essential for controlling the amount of current that flows through a circuit, thereby protecting sensitive components from damage and ensuring optimal performance.

B. Types of Resistors Commonly Produced

1. **Fixed Resistors**: These resistors have a predetermined resistance value that does not change. They are widely used in various applications, including voltage dividers and current limiters.

2. **Variable Resistors**: Also known as potentiometers or rheostats, these resistors allow users to adjust the resistance value. They are commonly found in applications such as volume controls and tuning circuits.

3. **Specialty Resistors**: This category includes precision resistors, high-power resistors, and temperature-sensitive resistors, each designed for specific applications and performance requirements.

C. Applications of Resistors in Various Industries

Resistors are utilized across multiple industries, including consumer electronics, automotive, telecommunications, and industrial automation. Their versatility makes them indispensable in devices such as smartphones, computers, medical equipment, and home appliances.

III. The Resistor Manufacturing Landscape in Shanghai

A. Historical Context of Resistor Production in Shanghai

Shanghai has a rich history in electronics manufacturing, dating back to the early 20th century. Over the decades, the city has evolved into a global manufacturing powerhouse, attracting numerous companies specializing in electronic components, including resistors.

B. Key Players in the Shanghai Resistor Manufacturing Industry

Several prominent manufacturers operate in Shanghai, contributing to the city's reputation as a leading resistor production hub. These companies leverage advanced technologies and skilled labor to produce high-quality resistors that meet international standards.

C. Overview of the Market Demand and Trends

The demand for resistors in Shanghai and globally is driven by the rapid growth of the electronics industry. Trends such as miniaturization, increased functionality, and the rise of smart devices are shaping the market, prompting manufacturers to innovate and adapt their production processes.

IV. The Mainstream Resistor Production Process

A. Raw Material Selection

The production of resistors begins with the careful selection of raw materials. Common materials used in resistor manufacturing include:

1. **Carbon**: Often used in fixed resistors, carbon provides a stable resistance value and is cost-effective.

2. **Metal Film**: Known for its precision and stability, metal film is commonly used in high-performance resistors.

3. **Wire-Wound**: This technology involves winding a metal wire around a ceramic core, providing high power ratings and precision.

Quality control measures are implemented to ensure that raw materials meet the required specifications, as the quality of materials directly impacts the performance of the final product.

B. Design and Engineering

The design phase is critical in resistor production. Engineers must define the specifications, including resistance value, tolerance, and temperature coefficient. Computer-aided design (CAD) tools play a vital role in this process, allowing for precise modeling and simulation of resistor performance before production begins.

C. Production Techniques

The manufacturing of resistors involves several key techniques:

1. **Thick Film Technology**: This method involves printing a resistive paste onto a substrate, which is then fired to create a solid resistor. Thick film resistors are known for their durability and are widely used in various applications.

2. **Thin Film Technology**: In this process, a thin layer of resistive material is deposited onto a substrate. Thin film resistors offer high precision and stability, making them suitable for applications requiring tight tolerances.

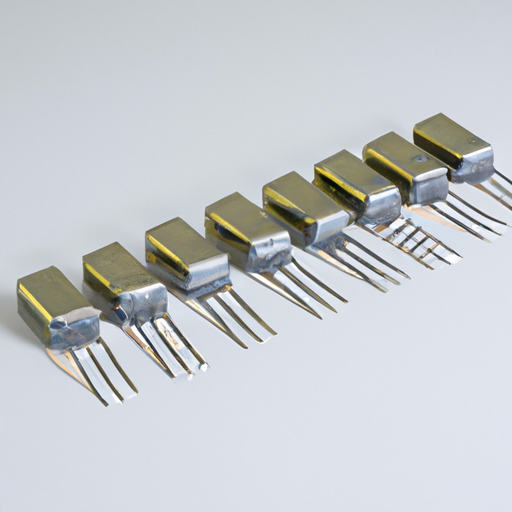

3. **Wire-Wound Technology**: As mentioned earlier, this technique involves winding a metal wire around a core. Wire-wound resistors are ideal for high-power applications due to their ability to dissipate heat effectively.

Step-by-Step Breakdown of the Production Process

1. **Material Preparation**: Raw materials are prepared and processed according to the specifications defined during the design phase.

2. **Component Fabrication**: The chosen production technique is employed to fabricate the resistor components. This may involve printing, deposition, or winding processes.

3. **Assembly and Soldering**: Once the components are fabricated, they are assembled and soldered together to form the final resistor.

4. **Encapsulation and Coating**: To protect the resistors from environmental factors, they are encapsulated and coated with protective materials. This step is crucial for ensuring the longevity and reliability of the resistors.

D. Quality Assurance

Quality assurance is a critical aspect of resistor production. Various testing methods are employed to ensure that resistors meet the required specifications. These tests may include:

1. **Electrical Testing**: Measuring resistance values, tolerance, and temperature coefficients.

2. **Environmental Testing**: Assessing the performance of resistors under different environmental conditions, such as temperature and humidity.

Manufacturers often seek certifications such as ISO and RoHS to demonstrate compliance with international standards and regulations.

E. Packaging and Distribution

Once the resistors pass quality assurance tests, they are packaged for distribution. Packaging techniques are designed to protect the resistors during transportation and storage. Logistics and supply chain considerations are also crucial, as timely delivery to customers is essential for maintaining competitiveness in the market.

V. Innovations and Trends in Resistor Production

A. Technological Advancements in Resistor Manufacturing

The resistor manufacturing industry is witnessing significant technological advancements. Automation and robotics are increasingly being integrated into production processes, enhancing efficiency and precision. Additionally, the use of advanced materials is enabling the development of resistors with improved performance characteristics.

B. Sustainability Practices in the Production Process

As environmental concerns grow, manufacturers are adopting sustainability practices in their production processes. This includes reducing waste, recycling materials, and minimizing energy consumption. Many companies are also exploring eco-friendly materials to create resistors that have a lower environmental impact.

C. Future Trends in Resistor Design and Production

The future of resistor manufacturing is likely to be shaped by trends such as miniaturization, increased integration with other components, and the development of smart resistors that can adapt to changing conditions in real-time. These innovations will drive the industry forward, meeting the evolving needs of the electronics market.

VI. Challenges in the Resistor Manufacturing Industry

A. Competition and Market Saturation

The resistor manufacturing industry is highly competitive, with numerous players vying for market share. This saturation can lead to price wars and reduced profit margins, challenging manufacturers to differentiate their products.

B. Supply Chain Disruptions

Global supply chain disruptions, exacerbated by events such as the COVID-19 pandemic, have impacted the availability of raw materials and components. Manufacturers must navigate these challenges to maintain production schedules and meet customer demands.

C. Regulatory Challenges and Compliance

Compliance with international regulations and standards can be complex and costly. Manufacturers must stay informed about changing regulations to ensure their products meet the necessary requirements.

VII. Conclusion

In summary, the resistor production process in Shanghai is a multifaceted operation that involves careful material selection, precise design, advanced manufacturing techniques, and rigorous quality assurance. As the industry continues to evolve, innovation and adaptation will be key to maintaining competitiveness in the global market. The future of resistor manufacturing in Shanghai and beyond looks promising, with advancements in technology and sustainability practices paving the way for continued growth and development.

VIII. References

- [Resistor Basics](https://www.electronics-tutorials.ws)

- [The History of Resistor Manufacturing](https://www.historyofelectronics.com)

- [Quality Standards in Electronics Manufacturing](https://www.iso.org)

- [Sustainability in Electronics Production](https://www.sustainableelectronics.org)

This blog post provides a comprehensive overview of the mainstream resistor production process in Shanghai, highlighting the importance of this industry in the global electronics landscape.