What are the Popular Resistor Box Product Types?

I. Introduction

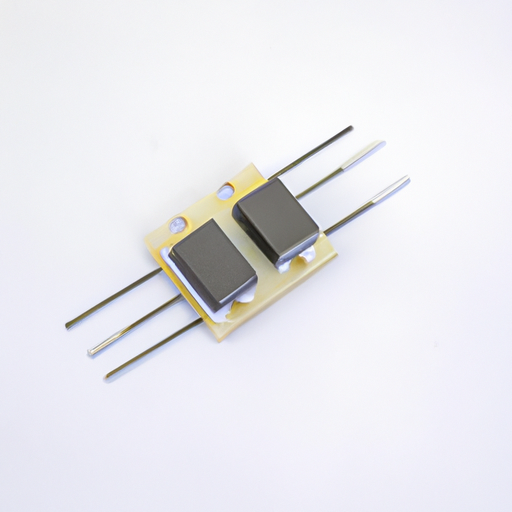

A. Definition of Resistor Boxes

Resistor boxes, also known as resistor networks or resistor banks, are essential tools in electronics that allow users to easily manage and manipulate resistance values in various circuits. These devices consist of multiple resistors housed in a single enclosure, enabling quick adjustments and testing without the need for individual resistors.

B. Importance of Resistor Boxes in Electronics

In the world of electronics, resistor boxes play a crucial role in circuit design, testing, and prototyping. They provide a convenient way to simulate different resistance values, which is vital for engineers and hobbyists alike. By using resistor boxes, users can save time and effort, streamline their workflow, and enhance the accuracy of their experiments.

C. Overview of the Article

This article will explore the various types of resistor boxes available in the market, their features, applications, and considerations for selection. We will also discuss popular brands and models, as well as the future trends in resistor box technology.

II. Types of Resistor Boxes

A. Fixed Resistor Boxes

1. Description and Functionality

Fixed resistor boxes contain a set of resistors with predetermined values. Users can select a specific resistance by connecting the appropriate terminals. These boxes are straightforward and easy to use, making them ideal for basic applications.

2. Common Applications

Fixed resistor boxes are commonly used in educational settings, laboratories, and for simple circuit testing. They are particularly useful for teaching fundamental concepts of resistance and Ohm's law.

3. Advantages and Disadvantages

**Advantages:**

- Simplicity of use

- Cost-effective

- Reliable for basic applications

**Disadvantages:**

- Limited flexibility in resistance values

- Not suitable for applications requiring variable resistance

B. Variable Resistor Boxes

1. Description and Functionality

Variable resistor boxes, also known as rheostats or potentiometers, allow users to adjust the resistance value continuously. This feature makes them versatile for various applications where fine-tuning is necessary.

2. Common Applications

These boxes are widely used in audio equipment, lighting control, and other applications where variable resistance is essential for performance optimization.

3. Advantages and Disadvantages

**Advantages:**

- Flexibility in resistance adjustment

- Ideal for applications requiring fine-tuning

**Disadvantages:**

- More complex than fixed resistor boxes

- Potential for wear and tear over time

C. Precision Resistor Boxes

1. Description and Functionality

Precision resistor boxes are designed for high accuracy and low tolerance levels. They are often used in calibration and testing environments where precise resistance values are critical.

2. Common Applications

These boxes are commonly found in laboratories, research facilities, and industries where precision measurements are essential, such as telecommunications and aerospace.

3. Advantages and Disadvantages

**Advantages:**

- High accuracy and reliability

- Suitable for critical applications

**Disadvantages:**

- Higher cost compared to standard resistor boxes

- May require specialized knowledge to operate effectively

D. Digital Resistor Boxes

1. Description and Functionality

Digital resistor boxes utilize electronic components to provide resistance values that can be adjusted via a digital interface. Users can select resistance values using buttons or a touchscreen, making them user-friendly and efficient.

2. Common Applications

These boxes are often used in automated testing setups, digital circuit design, and applications where quick adjustments are necessary.

3. Advantages and Disadvantages

**Advantages:**

- Easy to use with digital interfaces

- Quick adjustments and precise control

**Disadvantages:**

- Dependence on power supply

- Potential for electronic failure

E. Analog Resistor Boxes

1. Description and Functionality

Analog resistor boxes provide resistance values through mechanical means, such as rotary switches or sliders. They offer a tactile experience for users who prefer hands-on control.

2. Common Applications

These boxes are often used in educational settings, prototyping, and applications where users prefer analog control over digital interfaces.

3. Advantages and Disadvantages

**Advantages:**

- Intuitive and tactile control

- No need for power supply

**Disadvantages:**

- Limited precision compared to digital options

- Potential for mechanical wear over time

III. Key Features to Consider When Choosing a Resistor Box

A. Resistance Range

The resistance range is a critical factor to consider, as it determines the versatility of the resistor box. Users should select a box that covers the range of resistance values they anticipate needing.

B. Tolerance Levels

Tolerance levels indicate how much the actual resistance can vary from the stated value. For precision applications, lower tolerance levels are preferable.

C. Power Rating

The power rating indicates how much power the resistor box can handle without overheating. Users should ensure that the power rating meets the requirements of their specific applications.

D. Temperature Coefficient

The temperature coefficient measures how much the resistance value changes with temperature. A low temperature coefficient is desirable for applications requiring stability across varying temperatures.

E. Form Factor and Size

The physical size and form factor of the resistor box can impact its usability and integration into existing setups. Users should consider the available space and mounting options.

F. Connectivity Options

Connectivity options, such as binding posts or banana plugs, can affect how easily the resistor box can be integrated into a circuit. Users should choose a box that offers compatible connectivity for their needs.

IV. Popular Brands and Models

A. Overview of Leading Manufacturers

Several manufacturers are known for producing high-quality resistor boxes, including:

Keysight Technologies: Renowned for precision instruments and testing equipment.

B&K Precision: Offers a range of resistor boxes suitable for various applications.

Fluke: Known for reliable and durable testing equipment.

B. Comparison of Popular Models

When comparing models, users should consider factors such as resistance range, accuracy, and user interface. For example, the Keysight 3458A is known for its precision, while the B&K Precision 8500 series offers a good balance of features and affordability.

C. User Reviews and Feedback

User reviews can provide valuable insights into the performance and reliability of different resistor boxes. Online forums and product review sites are excellent resources for gathering feedback from other users.

V. Applications of Resistor Boxes

A. Educational Purposes

Resistor boxes are widely used in educational settings to teach students about electrical concepts, circuit design, and the behavior of resistors in various configurations.

B. Research and Development

In research and development, resistor boxes facilitate experimentation and testing, allowing engineers to quickly adjust resistance values and observe the effects on circuit performance.

C. Prototyping and Testing

Prototyping often requires rapid adjustments to circuit parameters. Resistor boxes provide a convenient solution for testing different configurations without the need for soldering or replacing individual resistors.

D. Industrial Applications

In industrial settings, resistor boxes are used for calibration, testing, and troubleshooting of electronic equipment, ensuring that systems operate within specified parameters.

VI. Conclusion

A. Summary of Key Points

Resistor boxes are invaluable tools in electronics, offering various types to suit different applications. From fixed and variable resistor boxes to precision and digital options, each type has its unique advantages and disadvantages.

B. Future Trends in Resistor Box Technology

As technology advances, we can expect to see more sophisticated resistor boxes with enhanced features, such as wireless connectivity, improved accuracy, and integration with software for automated testing.

C. Final Thoughts on Choosing the Right Resistor Box

When selecting a resistor box, users should consider their specific needs, including resistance range, tolerance, and application requirements. By understanding the different types and features available, users can make informed decisions that enhance their electronic projects.

VII. References

- Electronic Components: Resistor Boxes. (n.d.). Retrieved from [source]

- Keysight Technologies. (n.d.). Resistor Box Overview. Retrieved from [source]

- B&K Precision. (n.d.). Product Catalog. Retrieved from [source]

- Fluke Corporation. (n.d.). Testing Equipment. Retrieved from [source]

This comprehensive overview of resistor box product types provides a solid foundation for understanding their importance in electronics and how to choose the right one for your needs.