What are the Popular Capacitor Models?

I. Introduction

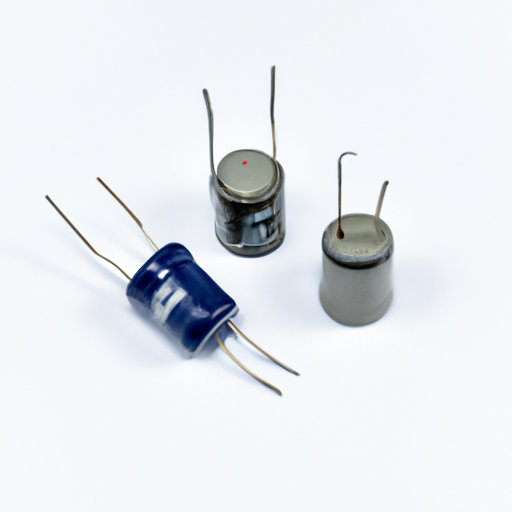

Capacitors are fundamental components in electronic circuits, serving as energy storage devices that can release energy when needed. They play a crucial role in various applications, from power supply stabilization to signal processing. Understanding the different types of capacitors and their characteristics is essential for engineers, hobbyists, and anyone involved in electronics. This article aims to provide an overview of popular capacitor models, their applications, and factors to consider when selecting the right capacitor for specific needs.

II. Basics of Capacitors

A. How Capacitors Work

Capacitors store electrical energy in an electric field, created by two conductive plates separated by an insulating material known as a dielectric. When a voltage is applied across the plates, an electric charge accumulates, allowing the capacitor to store energy. The amount of charge a capacitor can hold is defined by its capacitance, measured in farads (F), with common subunits being microfarads (µF) and picofarads (pF).

B. Types of Capacitors

Capacitors can be categorized based on their construction and functionality:

1. **Polarized vs. Non-Polarized**: Polarized capacitors, such as electrolytic capacitors, have a positive and negative terminal and must be connected correctly in a circuit. Non-polarized capacitors, like ceramic and film capacitors, can be connected in either direction.

2. **Fixed vs. Variable Capacitors**: Fixed capacitors have a set capacitance value, while variable capacitors allow for adjustment of capacitance, making them useful in tuning applications.

III. Popular Capacitor Models

A. Ceramic Capacitors

**Description and Characteristics**: Ceramic capacitors are made from ceramic materials and are known for their small size, low cost, and reliability. They are available in various capacitance values and voltage ratings.

**Applications and Advantages**: Commonly used in decoupling and filtering applications, ceramic capacitors are favored for their stability and low equivalent series resistance (ESR). They are widely used in consumer electronics, automotive applications, and RF circuits.

**Common Subtypes**: Ceramic capacitors are classified into Class 1 (temperature-stable) and Class 2 (higher capacitance but less stable) types, each suited for different applications.

B. Electrolytic Capacitors

**Description and Characteristics**: Electrolytic capacitors are polarized capacitors that use an electrolyte as one of the plates. They typically offer high capacitance values in a relatively small package.

**Applications and Advantages**: These capacitors are commonly used in power supply circuits for smoothing and filtering applications due to their high capacitance and voltage ratings. They are ideal for applications requiring significant energy storage.

**Limitations and Considerations**: Electrolytic capacitors have a limited lifespan and can be sensitive to temperature and voltage fluctuations. They also have higher ESR compared to other types, which can affect performance in high-frequency applications.

C. Tantalum Capacitors

**Description and Characteristics**: Tantalum capacitors are similar to electrolytic capacitors but use tantalum metal as the anode. They are known for their high capacitance and stable performance.

**Applications and Advantages**: Tantalum capacitors are often used in compact electronic devices, such as smartphones and tablets, due to their small size and reliability. They offer better performance than electrolytic capacitors in terms of ESR and temperature stability.

**Comparison with Electrolytic Capacitors**: While tantalum capacitors can handle higher frequencies and have a longer lifespan, they are more expensive and can be sensitive to voltage spikes, leading to catastrophic failure if not used within specified limits.

D. Film Capacitors

**Description and Characteristics**: Film capacitors are made from thin plastic films as the dielectric material. They are non-polarized and known for their excellent stability and low ESR.

**Applications and Advantages**: These capacitors are widely used in audio applications, timing circuits, and power electronics due to their reliability and performance. They are also resistant to moisture and have a long lifespan.

**Types of Film Capacitors**: Common types include polyester, polypropylene, and polystyrene capacitors, each with unique characteristics suited for specific applications.

E. Supercapacitors

**Description and Characteristics**: Supercapacitors, also known as ultracapacitors, have a much higher capacitance than traditional capacitors, allowing them to store significant amounts of energy.

**Applications and Advantages**: They are used in applications requiring rapid charge and discharge cycles, such as energy storage systems, regenerative braking in electric vehicles, and backup power supplies. Supercapacitors can bridge the gap between traditional capacitors and batteries.

**Differences from Traditional Capacitors**: Unlike traditional capacitors, supercapacitors can store energy for longer periods and have higher energy density, making them suitable for applications where quick bursts of energy are needed.

F. Mica Capacitors

**Description and Characteristics**: Mica capacitors use mica as the dielectric material, known for their stability and precision.

**Applications and Advantages**: They are often used in high-frequency applications, such as RF circuits and oscillators, due to their low loss and high stability over temperature and voltage.

**Use in High-Frequency Applications**: Mica capacitors are preferred in applications where performance and reliability are critical, such as in communication equipment and precision instruments.

G. Aluminum and Niobium Capacitors

**Description and Characteristics**: Aluminum capacitors are similar to electrolytic capacitors but use aluminum oxide as the dielectric. Niobium capacitors are a newer technology that offers improved performance.

**Applications and Advantages**: Both types are used in power supply circuits and energy storage applications. They provide good performance in terms of capacitance and voltage ratings.

**Comparison with Other Capacitor Types**: While aluminum capacitors are widely used, niobium capacitors offer advantages in terms of stability and reliability, making them suitable for demanding applications.

IV. Factors Influencing Capacitor Selection

When selecting a capacitor for a specific application, several factors must be considered:

A. Capacitance Value and Tolerance

The required capacitance value and its tolerance are critical for ensuring the capacitor meets the circuit's needs.

B. Voltage Rating

The voltage rating must exceed the maximum voltage the capacitor will experience in the circuit to prevent breakdown.

C. Temperature Coefficient

Different capacitors have varying temperature coefficients, affecting their performance in temperature-sensitive applications.

D. Size and Form Factor

The physical size and form factor of the capacitor can impact its suitability for specific designs, especially in compact electronic devices.

E. Frequency Response

Capacitors behave differently at various frequencies, so understanding the frequency response is essential for applications involving AC signals.

V. Applications of Capacitors

Capacitors are used in a wide range of applications, including:

A. Power Supply Circuits

Capacitors stabilize voltage and smooth out fluctuations in power supply circuits, ensuring consistent performance.

B. Signal Coupling and Decoupling

They are used to couple and decouple signals in audio and RF applications, allowing for clear signal transmission.

C. Timing Applications

Capacitors are integral to timing circuits, where they work with resistors to create time delays.

D. Energy Storage Systems

In renewable energy systems, capacitors store energy for later use, helping to balance supply and demand.

E. Audio and RF Applications

Capacitors play a crucial role in audio equipment and RF circuits, ensuring high-quality sound and signal integrity.

VI. Future Trends in Capacitor Technology

A. Advancements in Materials and Manufacturing

Ongoing research is focused on developing new materials and manufacturing techniques to enhance capacitor performance and reduce costs.

B. Emerging Applications in Renewable Energy

As renewable energy sources grow, capacitors will play a vital role in energy storage and management systems.

C. Miniaturization and Integration with Other Components

The trend toward smaller, more integrated electronic devices will drive the development of compact capacitors that can fit into tight spaces without sacrificing performance.

VII. Conclusion

In summary, capacitors are essential components in modern electronics, with various models suited for different applications. Understanding the characteristics and advantages of popular capacitor types, such as ceramic, electrolytic, tantalum, film, supercapacitors, mica, and aluminum/niobium capacitors, is crucial for selecting the right component for specific needs. As technology advances, the importance of capacitors will continue to grow, making it essential for engineers and enthusiasts to stay informed about the latest developments in capacitor technology.

VIII. References

For further reading and resources on capacitors, consider exploring industry standards, technical papers, and manufacturer datasheets. Understanding the guidelines for capacitor selection and usage will enhance your knowledge and application of these vital electronic components.