What are the Product Features of High Voltage Capacitors?

I. Introduction

High voltage capacitors are essential components in various electrical systems, playing a critical role in energy storage, power conditioning, and signal processing. Defined as capacitors designed to operate at voltages significantly higher than standard capacitors, these devices are crucial in applications ranging from power electronics to telecommunications. This article aims to explore the key product features of high voltage capacitors, their applications, and considerations for selection, providing a comprehensive understanding of their importance in modern technology.

II. Basic Principles of High Voltage Capacitors

A. Explanation of Capacitance and Voltage Ratings

Capacitance is the ability of a capacitor to store electrical energy in an electric field, measured in farads (F). Voltage rating, on the other hand, indicates the maximum voltage a capacitor can handle without breaking down. High voltage capacitors typically have voltage ratings exceeding 1,000 volts, making them suitable for demanding applications.

B. How High Voltage Capacitors Function in Electrical Circuits

High voltage capacitors function by storing energy when voltage is applied and releasing it when needed. They can smooth out voltage fluctuations, filter signals, and provide reactive power support in electrical circuits, enhancing overall system stability and efficiency.

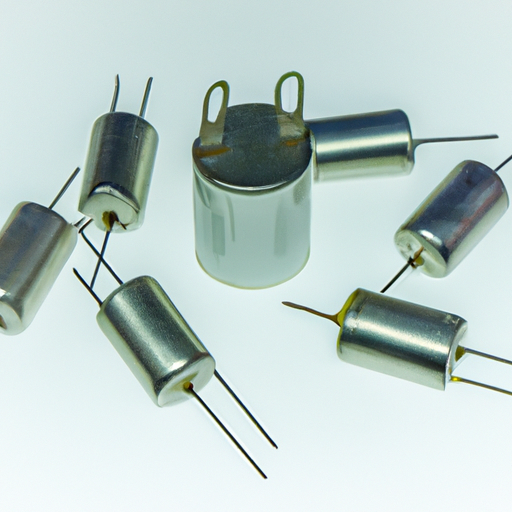

C. Types of High Voltage Capacitors

High voltage capacitors come in various types, including ceramic, film, and electrolytic capacitors. Each type has unique characteristics that make it suitable for specific applications. For instance, ceramic capacitors are known for their stability and reliability, while film capacitors offer excellent performance in high-frequency applications.

III. Key Product Features of High Voltage Capacitors

A. Voltage Rating

1. Definition and Significance

The voltage rating of a capacitor is a critical feature that determines its suitability for specific applications. It indicates the maximum voltage the capacitor can withstand without risk of failure. Exceeding this rating can lead to catastrophic failure, including dielectric breakdown and explosion.

2. Common Voltage Ratings in High Voltage Applications

High voltage capacitors are available in various voltage ratings, commonly ranging from 1 kV to over 100 kV. The choice of voltage rating depends on the application requirements, with higher ratings typically used in industrial and power generation settings.

B. Capacitance Value

1. Importance of Capacitance in Energy Storage

Capacitance value is another crucial feature, as it determines the amount of energy a capacitor can store. Higher capacitance values allow for greater energy storage, which is essential in applications requiring significant power bursts or energy smoothing.

2. Range of Capacitance Values Available

High voltage capacitors are available in a wide range of capacitance values, from picofarads (pF) to microfarads (µF). The specific value needed will depend on the application, with larger capacitance values typically used in power electronics and energy storage systems.

C. Dielectric Material

1. Types of Dielectric Materials Used

The dielectric material used in a capacitor significantly impacts its performance and reliability. Common dielectric materials for high voltage capacitors include polypropylene, polyester, and ceramic. Each material has unique properties that affect capacitance stability, temperature tolerance, and voltage handling.

2. Impact of Dielectric Material on Performance and Reliability

The choice of dielectric material can influence the capacitor's lifespan, temperature coefficient, and overall reliability. For instance, polypropylene capacitors are known for their low losses and high stability, making them ideal for high-frequency applications.

D. Temperature Coefficient

1. Explanation of Temperature Coefficient and Its Relevance

The temperature coefficient indicates how a capacitor's capacitance changes with temperature. A low temperature coefficient is desirable, as it ensures stable performance across varying environmental conditions.

2. Typical Temperature Ranges for High Voltage Capacitors

High voltage capacitors are designed to operate within specific temperature ranges, typically from -40°C to +85°C. Some specialized capacitors can handle even more extreme conditions, making them suitable for harsh environments.

E. Ripple Current Rating

1. Definition and Importance in AC Applications

Ripple current rating refers to the maximum AC current a capacitor can handle without overheating. This feature is particularly important in applications where capacitors are subjected to fluctuating currents, such as in power supplies and inverters.

2. How Ripple Current Affects Capacitor Performance

Exceeding the ripple current rating can lead to increased heat generation, reduced efficiency, and ultimately, capacitor failure. Therefore, selecting a capacitor with an appropriate ripple current rating is crucial for ensuring reliable operation.

F. Equivalent Series Resistance (ESR)

1. Explanation of ESR and Its Impact on Efficiency

Equivalent Series Resistance (ESR) is a measure of the resistive losses within a capacitor. A lower ESR indicates higher efficiency, as less energy is wasted as heat during operation.

2. Importance of Low ESR in High Voltage Applications

In high voltage applications, low ESR is particularly important, as it helps maintain efficiency and prolongs the lifespan of the capacitor. Capacitors with high ESR can lead to overheating and reduced performance, making careful selection essential.

G. Size and Form Factor

1. Physical Dimensions and Their Implications for Design

The size and form factor of high voltage capacitors can significantly impact their integration into electrical systems. Smaller capacitors are often preferred for compact designs, while larger capacitors may be necessary for higher capacitance values.

2. Common Form Factors in High Voltage Capacitors

High voltage capacitors come in various form factors, including cylindrical, rectangular, and surface-mount designs. The choice of form factor will depend on the specific application and available space in the system.

H. Lifespan and Reliability

1. Factors Affecting Lifespan

The lifespan of high voltage capacitors can be influenced by several factors, including temperature, voltage stress, and environmental conditions. Capacitors operating at or near their maximum ratings will typically have shorter lifespans.

2. Importance of Reliability in Critical Applications

In critical applications, such as medical equipment and power systems, reliability is paramount. Selecting high-quality capacitors with proven reliability can help ensure the longevity and safety of the overall system.

IV. Applications of High Voltage Capacitors

A. Power Electronics

High voltage capacitors play a vital role in power electronics, particularly in inverters and converters. They help smooth out voltage fluctuations and provide reactive power support, which is essential for maintaining system stability in renewable energy systems.

B. Industrial Equipment

In industrial settings, high voltage capacitors are used in motor drives and power supplies. They help improve efficiency and performance in manufacturing and automation processes, ensuring reliable operation of machinery.

C. Telecommunications

High voltage capacitors are crucial in telecommunications, where they help maintain signal integrity and support signal processing. Their ability to handle high voltages and provide stable performance is essential for reliable communication systems.

D. Medical Equipment

In the medical field, high voltage capacitors are used in imaging and diagnostic devices, such as MRI machines and X-ray equipment. Their reliability and performance are critical, as any failure could have serious implications for patient care.

V. Considerations When Selecting High Voltage Capacitors

A. Application Requirements

When selecting high voltage capacitors, it is essential to match their features to the specific application requirements. Understanding the system's voltage, capacitance, and environmental conditions is crucial for ensuring optimal performance.

B. Manufacturer Specifications

Evaluating product datasheets and manufacturer specifications is vital in selecting the right capacitor. Reputable manufacturers provide detailed information on performance characteristics, ensuring that the chosen capacitor meets the necessary standards.

C. Cost vs. Performance

Balancing budget constraints with performance needs is a common challenge when selecting high voltage capacitors. While it may be tempting to choose lower-cost options, investing in high-quality capacitors can lead to better long-term performance and reliability.

VI. Conclusion

High voltage capacitors are indispensable components in modern electrical systems, offering essential features that enhance performance and reliability. Understanding their key product features, including voltage rating, capacitance value, dielectric material, and more, is crucial for selecting the right capacitor for specific applications. As technology continues to evolve, the role of high voltage capacitors will remain vital in powering the future.

VII. References

For further information on high voltage capacitors, consider exploring the following resources:

- Industry standards and guidelines related to high voltage capacitors

- Manufacturer datasheets and technical specifications

- Academic articles and publications on capacitor technology and applications

By understanding the intricacies of high voltage capacitors, engineers and designers can make informed decisions that enhance the performance and reliability of their electrical systems.