The Latest Resistor and Resistor Specifications

I. Introduction

A. Definition of Resistors

Resistors are fundamental electronic components that limit the flow of electric current in a circuit. They are designed to provide a specific resistance value, measured in ohms (Ω), which determines how much current will flow for a given voltage according to Ohm's Law (V = IR).

B. Importance of Resistors in Electronic Circuits

Resistors play a crucial role in electronic circuits by controlling current, dividing voltages, and protecting sensitive components from excessive current. They are used in a wide range of applications, from simple circuits in household electronics to complex systems in industrial machinery. Without resistors, circuits would be prone to damage and malfunction.

C. Overview of the Article's Purpose

This article aims to provide an in-depth look at the latest developments in resistor technology, including various types of resistors, their specifications, recent advances, applications, and guidance on selecting the right resistor for specific needs.

II. Types of Resistors

A. Fixed Resistors

Fixed resistors have a constant resistance value and are the most commonly used type in electronic circuits. They come in various materials and constructions:

1. **Carbon Composition Resistors**: Made from a mixture of carbon and a binding material, these resistors are known for their high energy absorption and are often used in high-power applications. However, they have a higher tolerance and lower stability compared to other types.

2. **Metal Film Resistors**: These resistors are made by depositing a thin layer of metal onto a ceramic substrate. They offer better stability and lower noise than carbon composition resistors, making them ideal for precision applications.

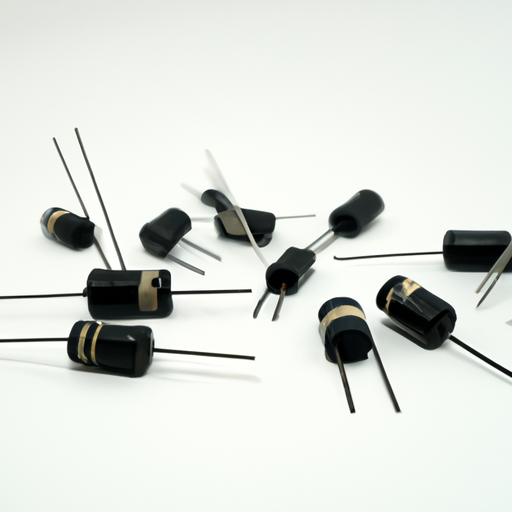

3. **Wirewound Resistors**: Constructed by winding a metal wire around a ceramic or fiberglass core, wirewound resistors can handle high power levels and are often used in power applications. They are known for their accuracy and stability.

B. Variable Resistors

Variable resistors allow for adjustable resistance values, making them versatile components in electronic circuits.

1. **Potentiometers**: These are three-terminal devices that can adjust voltage levels in a circuit. They are commonly used in volume controls and other applications where variable resistance is needed.

2. **Rheostats**: Similar to potentiometers but typically used for higher current applications, rheostats allow for the adjustment of current flow in a circuit.

C. Specialty Resistors

Specialty resistors are designed for specific applications and include:

1. **Thermistors**: Temperature-sensitive resistors that change resistance with temperature variations. They are widely used in temperature sensing and control applications.

2. **Photoresistors**: Also known as light-dependent resistors (LDRs), these components change resistance based on light exposure. They are commonly used in light-sensing applications.

3. **Varistors**: Voltage-dependent resistors that protect circuits from voltage spikes. They are often used in surge protection devices.

III. Resistor Specifications

A. Resistance Value

1. **Ohm (Ω) Measurement**: The resistance value of a resistor is measured in ohms, which quantifies how much the resistor opposes the flow of current.

2. **Tolerance Levels**: Tolerance indicates the precision of the resistor's resistance value. Common tolerance levels include ±1%, ±5%, and ±10%, with lower percentages indicating higher precision.

B. Power Rating

1. **Definition and Importance**: The power rating of a resistor indicates the maximum amount of power it can dissipate without being damaged. Exceeding this rating can lead to overheating and failure.

2. **Common Power Ratings**: Resistors come in various power ratings, typically ranging from 1/8 watt to several hundred watts, depending on their application.

C. Temperature Coefficient

1. **Explanation of Temperature Coefficient**: The temperature coefficient measures how much a resistor's resistance changes with temperature. It is expressed in parts per million per degree Celsius (ppm/°C).

2. **Impact on Performance**: A low temperature coefficient is desirable for precision applications, as it ensures that the resistor maintains its resistance value across a range of temperatures.

D. Voltage Rating

1. **Definition and Importance**: The voltage rating indicates the maximum voltage that can be applied across a resistor without causing breakdown or failure.

2. **Breakdown Voltage Considerations**: It is crucial to select resistors with appropriate voltage ratings to prevent damage in high-voltage applications.

IV. Recent Advances in Resistor Technology

A. Development of High-Precision Resistors

Recent advancements have led to the development of high-precision resistors that offer tighter tolerances and improved stability. These resistors are essential in applications requiring accurate measurements, such as in instrumentation and medical devices.

B. Innovations in Material Science

1. **Use of Nanotechnology**: The incorporation of nanotechnology in resistor manufacturing has resulted in improved performance characteristics, such as reduced noise and enhanced thermal stability.

2. **Advanced Coating Techniques**: New coating techniques have been developed to enhance the durability and performance of resistors, making them more suitable for harsh environments.

C. Miniaturization Trends

1. **Surface Mount Resistors**: The trend towards miniaturization has led to the widespread use of surface mount resistors, which are smaller and can be easily integrated into compact circuit designs.

2. **Impact on Circuit Design**: The ability to use smaller components allows for more complex and efficient circuit designs, enabling the development of advanced electronic devices.

V. Applications of Resistors

A. Consumer Electronics

Resistors are ubiquitous in consumer electronics, from smartphones to televisions, where they help regulate current and voltage levels.

B. Automotive Industry

In the automotive sector, resistors are used in various applications, including engine control units, sensors, and lighting systems, ensuring reliable performance and safety.

C. Industrial Automation

Resistors play a vital role in industrial automation systems, where they are used in control circuits, motor drives, and safety devices.

D. Telecommunications

In telecommunications, resistors are essential for signal processing, impedance matching, and ensuring the integrity of data transmission.

VI. Selecting the Right Resistor

A. Factors to Consider

1. **Application Requirements**: Understanding the specific requirements of the application, such as resistance value, power rating, and tolerance, is crucial for selecting the right resistor.

2. **Environmental Conditions**: Consideration of environmental factors, such as temperature, humidity, and exposure to chemicals, is essential to ensure the resistor's longevity and reliability.

B. Common Mistakes to Avoid

One common mistake is selecting a resistor with an insufficient power rating, which can lead to overheating and failure. Additionally, overlooking tolerance levels can result in inaccurate circuit performance.

C. Resources for Further Research

For those looking to deepen their understanding of resistors, numerous resources are available, including academic journals, industry publications, and online databases.

VII. Conclusion

A. Summary of Key Points

Resistors are essential components in electronic circuits, with various types and specifications tailored to meet specific needs. Recent advancements in technology have led to the development of high-precision resistors and innovative materials, enhancing their performance and applications.

B. Future Trends in Resistor Technology

As technology continues to evolve, we can expect further innovations in resistor design, including increased miniaturization, improved materials, and enhanced precision.

C. Final Thoughts on the Importance of Resistors in Modern Electronics

In conclusion, resistors remain a cornerstone of modern electronics, enabling the functionality and reliability of countless devices. Understanding their specifications and advancements is crucial for engineers and hobbyists alike, ensuring the successful design and implementation of electronic circuits.

VIII. References

A. Academic Journals

- IEEE Transactions on Electron Devices

- Journal of Electronic Materials

B. Industry Publications

- Electronic Design Magazine

- EDN Network

C. Online Resources and Databases

- Digi-Key Electronics

- Mouser Electronics

This comprehensive overview of resistors and their specifications highlights their significance in the ever-evolving landscape of electronics, providing valuable insights for anyone involved in the field.