What are the Advantages of Thin Film Resistor Products?

I. Introduction

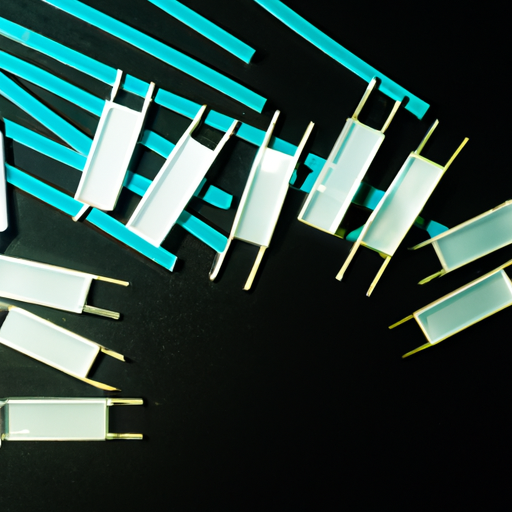

In the world of electronics, resistors play a crucial role in controlling current flow and ensuring the proper functioning of circuits. Among the various types of resistors available, thin film resistors have gained significant attention due to their unique properties and advantages. Thin film resistors are made by depositing a thin layer of resistive material onto a substrate, resulting in components that offer high precision, stability, and reliability. This blog post will explore the advantages of thin film resistors, their manufacturing process, applications, and how they compare to other resistor types.

II. Manufacturing Process of Thin Film Resistors

The manufacturing of thin film resistors involves a sophisticated thin film deposition process. This process typically includes techniques such as sputtering, evaporation, or chemical vapor deposition, which allow for the creation of a uniform and controlled resistive layer. The thin film is then patterned using photolithography to define the resistor's shape and dimensions.

When compared to thick film and wire-wound resistors, thin film resistors stand out due to their superior manufacturing precision. Thick film resistors are made by printing a paste of conductive material onto a substrate and then firing it, which can lead to variations in resistance values. Wire-wound resistors, on the other hand, are constructed by winding a wire around a core, which can introduce inductance and limit their performance in high-frequency applications. The quality control measures in thin film resistor manufacturing ensure that they maintain tight tolerances and consistent performance, making them ideal for precision applications.

III. Key Advantages of Thin Film Resistors

A. High Precision and Accuracy

One of the most significant advantages of thin film resistors is their high precision and accuracy. They can achieve tolerance levels as low as ±0.01%, making them suitable for applications where exact resistance values are critical. Additionally, thin film resistors exhibit a low temperature coefficient of resistance (TCR), typically around ±5 ppm/°C or better. This means that their resistance value changes very little with temperature fluctuations, ensuring stable performance in varying environmental conditions.

B. Stability and Reliability

Thin film resistors are known for their long-term stability and reliability. They are less susceptible to drift over time compared to other resistor types, which can degrade due to environmental factors such as humidity, temperature, and mechanical stress. This stability makes them an excellent choice for applications that require consistent performance over extended periods, such as in precision measurement instruments and aerospace electronics.

C. Low Noise Characteristics

In sensitive applications, such as audio equipment and precision measurement devices, noise can significantly impact performance. Thin film resistors are designed to have low noise characteristics, which is essential for maintaining signal integrity. Compared to thick film and wire-wound resistors, thin film resistors produce less thermal and flicker noise, making them preferable for high-performance applications.

D. Compact Size and Integration

As electronic devices continue to shrink in size, the demand for compact components has increased. Thin film resistors are inherently smaller than their thick film and wire-wound counterparts, allowing for space-saving benefits in circuit design. Their small footprint makes them compatible with modern circuit layouts, enabling engineers to design more compact and efficient electronic systems.

E. Customizability

Thin film resistors offer a high degree of customizability, allowing manufacturers to tailor specifications to meet specific application requirements. This includes variations in resistance values, temperature coefficients, and materials used in the resistive layer. The ability to customize thin film resistors makes them suitable for a wide range of applications, from consumer electronics to specialized industrial equipment.

IV. Applications of Thin Film Resistors

Thin film resistors find applications across various industries due to their unique advantages. Some notable applications include:

A. Use in Precision Measurement Instruments

Instruments such as digital multimeters, oscilloscopes, and other measurement devices require high-precision components to ensure accurate readings. Thin film resistors are often used in these applications due to their tight tolerances and low noise characteristics.

B. Role in Telecommunications

Telecommunications equipment relies on high-performance components to maintain signal integrity and reliability. Thin film resistors are used in various devices, including amplifiers, filters, and signal processing units, where precision and stability are paramount.

C. Applications in Medical Devices

In the medical field, devices such as patient monitors, diagnostic equipment, and imaging systems require components that can deliver accurate and reliable performance. Thin film resistors are commonly used in these applications to ensure the safety and effectiveness of medical devices.

D. Importance in Automotive Electronics

As vehicles become more advanced and reliant on electronic systems, the demand for high-quality components has increased. Thin film resistors are used in automotive applications such as engine control units, safety systems, and infotainment systems, where precision and reliability are critical.

E. Use in Consumer Electronics

From smartphones to home appliances, consumer electronics benefit from the advantages of thin film resistors. Their compact size, low noise, and high precision make them ideal for a wide range of applications in this sector.

V. Comparison with Other Resistor Types

A. Thick Film Resistors

Thick film resistors are often more cost-effective than thin film resistors, making them a popular choice for many applications. However, they typically have higher tolerances and temperature coefficients, which can limit their use in precision applications.

B. Wire-Wound Resistors

Wire-wound resistors are known for their high power handling capabilities and low resistance values. However, they can introduce inductance, which may not be suitable for high-frequency applications. Thin film resistors, with their low noise and compact size, are often preferred in these scenarios.

C. Carbon Composition Resistors

Carbon composition resistors are less expensive and can handle high energy pulses, but they are less stable and have higher noise levels compared to thin film resistors. For applications requiring precision and reliability, thin film resistors are the better choice.

VI. Future Trends in Thin Film Resistor Technology

As technology continues to evolve, so does the field of thin film resistors. Innovations in materials and manufacturing techniques are paving the way for even more advanced resistor products. For instance, the development of new resistive materials can enhance performance characteristics, while advancements in deposition techniques can further improve precision and reduce costs.

The trend toward miniaturization in electronics is also driving the demand for thin film resistors. As devices become smaller and more complex, the need for compact, high-performance components will only increase. This presents opportunities for thin film resistors to play a vital role in emerging technologies, such as wearable devices, IoT applications, and advanced automotive systems.

VII. Conclusion

In summary, thin film resistors offer a range of advantages that make them an essential component in modern electronic circuits. Their high precision, stability, low noise characteristics, compact size, and customizability set them apart from other resistor types. As technology continues to advance, the role of thin film resistors in various applications will only grow, driving innovation and improving the performance of electronic devices. Selecting the right resistor type for specific applications is crucial, and thin film resistors are often the best choice for achieving the desired performance and reliability.