What Industries Are the Application Scenarios of Fuse Resistors Included?

I. Introduction

In the realm of electrical engineering, fuse resistors play a pivotal role in ensuring the safety and efficiency of electrical circuits. These components are designed to protect circuits from overcurrent conditions, thereby preventing damage to sensitive electronic devices. This blog post aims to explore the various industries that utilize fuse resistors, highlighting their application scenarios and the significance of these components in modern technology.

II. Understanding Fuse Resistors

A. Explanation of Fuse Resistors

Fuse resistors are specialized resistive components that combine the functions of a resistor and a fuse. They are designed to limit current flow while also providing overcurrent protection. When the current exceeds a predetermined threshold, the fuse element within the resistor melts, interrupting the circuit and preventing further damage.

1. Functionality

The primary function of fuse resistors is to protect electronic circuits from excessive current. They act as a safeguard, ensuring that if a fault occurs, the circuit is interrupted before any significant damage can occur.

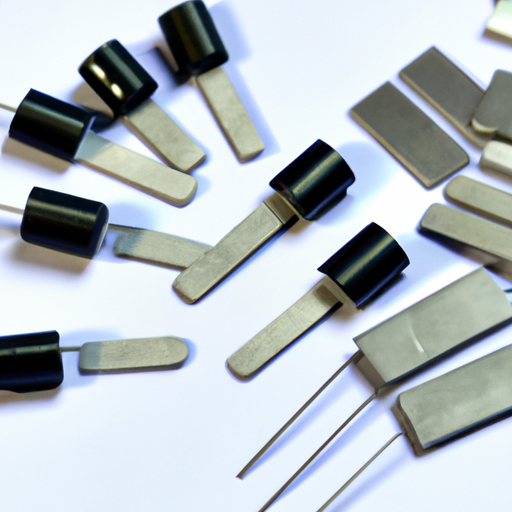

2. Construction

Fuse resistors are typically constructed using a resistive element encased in a protective housing. The resistive element can be made from various materials, depending on the type of fuse resistor being used.

B. Types of Fuse Resistors

There are several types of fuse resistors, each with unique characteristics suited for different applications.

1. Wirewound Fuse Resistors

These resistors are made by winding a wire around a ceramic or insulating core. They are known for their high power ratings and stability under varying temperatures.

2. Thick Film Fuse Resistors

Thick film fuse resistors are created by applying a thick layer of resistive material onto a substrate. They are compact and suitable for surface mount applications.

3. Thin Film Fuse Resistors

Thin film fuse resistors are made by depositing a thin layer of resistive material. They offer high precision and are often used in applications requiring tight tolerances.

C. Key Characteristics

When selecting a fuse resistor, several key characteristics must be considered:

1. Resistance Value

The resistance value determines how much current the resistor will allow to pass before it activates the fuse element.

2. Power Rating

The power rating indicates the maximum power the resistor can handle without failing. This is crucial for ensuring the resistor can withstand the operational conditions of the circuit.

3. Temperature Coefficient

The temperature coefficient indicates how the resistance value changes with temperature. A low temperature coefficient is desirable for maintaining consistent performance across varying temperatures.

III. Key Industries Utilizing Fuse Resistors

Fuse resistors find applications across a wide range of industries, each benefiting from their unique properties.

A. Consumer Electronics

In the consumer electronics sector, fuse resistors are commonly used in smartphones, tablets, and home appliances. They protect sensitive components from overcurrent conditions, ensuring the longevity and reliability of devices.

B. Automotive Industry

The automotive industry has seen a significant shift towards electric vehicles (EVs), where fuse resistors play a crucial role in battery management systems. They also provide protection in safety systems, such as airbags and anti-lock braking systems, ensuring that these critical components function correctly.

C. Telecommunications

In telecommunications, fuse resistors are essential for network equipment and signal processing applications. They help maintain signal integrity and protect against surges that could disrupt communication systems.

D. Industrial Automation

The industrial automation sector relies on fuse resistors in robotics and control systems. They ensure that machinery operates safely and efficiently, preventing damage from electrical faults.

E. Medical Devices

In the medical field, fuse resistors are used in diagnostic equipment and life-support systems. Their reliability is paramount, as they help protect sensitive medical devices that can be critical to patient care.

F. Renewable Energy

With the rise of renewable energy sources, fuse resistors are increasingly used in solar inverters and wind turbines. They help manage power flow and protect against overcurrent conditions, ensuring the stability of energy systems.

IV. Application Scenarios of Fuse Resistors

A. Overcurrent Protection

1. Explanation of Overcurrent

Overcurrent occurs when the current flowing through a circuit exceeds its rated capacity. This can lead to overheating, component failure, and even fire hazards.

2. How Fuse Resistors Provide Protection

Fuse resistors are designed to interrupt the circuit when overcurrent conditions are detected. By melting the fuse element, they prevent excessive current from damaging the circuit components.

B. Voltage Regulation

1. Importance of Voltage Stability

Voltage stability is crucial for the proper functioning of electronic devices. Fluctuations in voltage can lead to erratic behavior or damage.

2. Role of Fuse Resistors in Regulation

Fuse resistors help maintain voltage levels by limiting current flow. This regulation ensures that devices operate within their specified voltage ranges, enhancing performance and reliability.

C. Signal Conditioning

1. Need for Signal Integrity

In many applications, maintaining signal integrity is essential for accurate data transmission and processing.

2. Application in Filtering and Amplification

Fuse resistors are used in signal conditioning circuits to filter out noise and amplify signals. They help ensure that the signals remain clear and undistorted, which is vital for effective communication.

D. Thermal Management

1. Importance of Heat Dissipation

Excessive heat can lead to component failure and reduced lifespan. Effective thermal management is essential in electronic design.

2. How Fuse Resistors Aid in Thermal Control

Fuse resistors can dissipate heat generated during operation, helping to maintain optimal temperatures within circuits. This thermal control is crucial for ensuring the longevity and reliability of electronic devices.

V. Advantages of Using Fuse Resistors

A. Enhanced Safety Features

Fuse resistors provide an added layer of safety by protecting circuits from overcurrent conditions, reducing the risk of fire and equipment damage.

B. Compact Design

Many fuse resistors are designed to be compact, making them suitable for applications where space is limited, such as in consumer electronics and automotive systems.

C. Cost-Effectiveness

Fuse resistors are often more cost-effective than traditional fuses and resistors, providing dual functionality at a lower overall cost.

D. Versatility in Applications

The versatility of fuse resistors allows them to be used in a wide range of applications across various industries, making them a valuable component in modern electronic design.

VI. Challenges and Considerations

A. Limitations of Fuse Resistors

While fuse resistors offer many advantages, they also have limitations, such as a finite lifespan and the need for replacement after activation.

B. Factors Influencing Selection

When selecting a fuse resistor, several factors must be considered, including environmental conditions, load requirements, and the specific application.

1. Environmental Conditions

Temperature, humidity, and exposure to chemicals can all impact the performance of fuse resistors.

2. Load Requirements

Understanding the load requirements of the circuit is essential for selecting the appropriate fuse resistor to ensure optimal performance.

C. Future Trends in Fuse Resistor Technology

As technology advances, we can expect to see improvements in fuse resistor design, including enhanced materials and manufacturing processes that increase reliability and performance.

VII. Conclusion

In summary, fuse resistors are integral components in various industries, providing essential protection and functionality in electrical circuits. Their ability to safeguard against overcurrent conditions, regulate voltage, and maintain signal integrity makes them invaluable in modern technology. As industries continue to evolve, the importance of fuse resistors will only grow, ensuring that electronic devices operate safely and efficiently.

VIII. References

- Academic Journals

- Industry Reports

- Manufacturer Specifications

In conclusion, understanding the application scenarios of fuse resistors across different industries highlights their significance in ensuring the safety and reliability of electronic devices. As technology continues to advance, the role of fuse resistors will remain crucial in the development of innovative solutions for various applications.