Manufacturing Processes of the Latest Aluminum Shell Resistors

I. Introduction

In the world of electronics, resistors play a crucial role in controlling the flow of electric current. Among the various types of resistors, aluminum shell resistors have gained significant attention due to their unique properties and advantages. These resistors are characterized by their aluminum casing, which not only provides structural integrity but also enhances thermal management. This blog post will delve into the manufacturing processes of the latest aluminum shell resistors, exploring their composition, fabrication techniques, and the innovations shaping their production.

II. Understanding Aluminum Shell Resistors

A. Composition and Structure

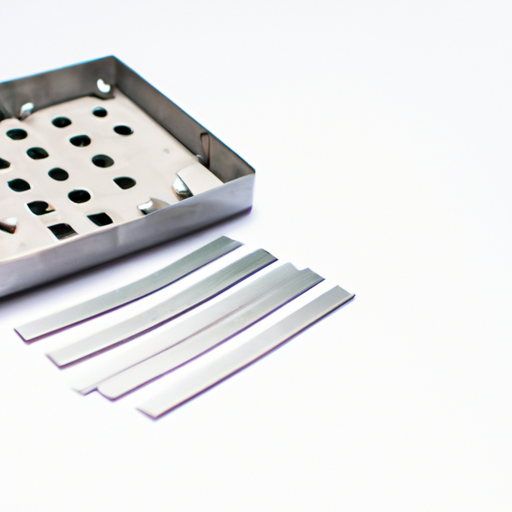

Aluminum shell resistors are composed of two primary materials: aluminum for the casing and a resistive material for the internal element. The aluminum shell serves as a protective barrier, while the resistive element is responsible for the resistor's functionality.

1. **Materials Used**: The aluminum casing is typically made from high-grade aluminum alloys, which offer excellent thermal conductivity and corrosion resistance. The resistive materials can vary, including carbon, metal film, or wire wound configurations, each providing different resistance values and thermal characteristics.

2. **Design Features**: The design of aluminum shell resistors often includes features such as heat sinks or fins to enhance heat dissipation. This design is crucial for maintaining performance under high load conditions.

B. Advantages of Aluminum Shell Resistors

Aluminum shell resistors offer several advantages over traditional resistors:

1. **Thermal Management**: The aluminum casing effectively dissipates heat, allowing the resistor to operate at higher power levels without overheating. This is particularly important in high-performance applications.

2. **Durability and Reliability**: The robust aluminum shell protects the internal components from environmental factors, making these resistors suitable for harsh conditions.

3. **Lightweight Properties**: Compared to other materials, aluminum is lightweight, which is beneficial for applications where weight is a critical factor, such as in aerospace and automotive industries.

III. Overview of Manufacturing Processes

The manufacturing of aluminum shell resistors involves several key processes, each critical to ensuring the final product meets quality and performance standards.

A. Raw Material Preparation

1. **Sourcing Aluminum and Resistive Materials**: The first step in the manufacturing process is sourcing high-quality aluminum and resistive materials. Manufacturers often establish relationships with trusted suppliers to ensure consistent quality.

2. **Quality Control of Raw Materials**: Before production begins, raw materials undergo rigorous quality control checks to verify their composition and properties. This step is essential to prevent defects in the final product.

B. Component Fabrication

1. **Aluminum Shell Production**: The aluminum shell is produced using methods such as die casting or extrusion.

- **Die Casting**: This process involves pouring molten aluminum into a mold, where it cools and solidifies into the desired shape. Die casting is known for its ability to produce complex shapes with high precision.

- **Extrusion**: In this method, aluminum is forced through a die to create long sections of material with a consistent cross-section. This technique is often used for creating heat sinks or other structural components.

2. **Resistor Element Fabrication**: The resistive element can be fabricated using various technologies:

- **Thin Film Technology**: This method involves depositing a thin layer of resistive material onto a substrate. Thin film resistors offer high precision and stability.

- **Thick Film Technology**: In this process, a thicker layer of resistive paste is printed onto a ceramic substrate and then fired to create the resistor. Thick film resistors are known for their robustness and versatility.

- **Wire Wound Technology**: This traditional method involves winding a resistive wire around a core. Wire wound resistors are ideal for high-power applications due to their excellent thermal performance.

C. Assembly Process

1. **Integration of Resistor Elements into Aluminum Shells**: Once the aluminum shells and resistor elements are fabricated, they are assembled. The resistor element is carefully placed inside the aluminum casing.

2. **Soldering and Bonding Techniques**: The integration process often involves soldering or bonding the resistor element to the aluminum shell. This step is critical for ensuring electrical connectivity and thermal transfer.

3. **Quality Assurance During Assembly**: Throughout the assembly process, quality assurance checks are conducted to ensure that each component is correctly integrated and meets specifications.

IV. Advanced Manufacturing Techniques

A. Automation in Production

1. **Robotics and CNC Machining**: The use of robotics and CNC (Computer Numerical Control) machining has revolutionized the manufacturing of aluminum shell resistors. Automation enhances precision, reduces production time, and minimizes human error.

2. **Benefits of Automation**: Automated processes allow for consistent quality and scalability in production. Manufacturers can quickly adapt to changing demands without compromising quality.

B. Surface Treatment and Finishing

1. **Anodizing**: Anodizing is a surface treatment process that enhances the corrosion resistance and aesthetic appeal of aluminum. This process involves electrochemically oxidizing the surface of the aluminum, creating a durable layer.

2. **Coating for Enhanced Performance**: Additional coatings may be applied to improve thermal performance or electrical insulation, further enhancing the resistor's capabilities.

V. Testing and Quality Control

A. Importance of Testing in Resistor Manufacturing

Testing is a critical component of the manufacturing process, ensuring that each resistor meets performance standards and specifications.

B. Types of Tests Conducted

1. **Electrical Testing**: This includes measuring resistance values, tolerance levels, and power ratings to ensure the resistor performs as expected.

2. **Thermal Testing**: Resistors are subjected to thermal cycling tests to evaluate their performance under varying temperature conditions.

3. **Mechanical Testing**: Mechanical tests assess the durability and structural integrity of the resistors, ensuring they can withstand physical stress.

C. Standards and Certifications

Manufacturers must adhere to industry standards and certifications, such as ISO and RoHS, to ensure their products are safe and reliable.

VI. Environmental Considerations

A. Sustainable Practices in Manufacturing

As environmental concerns grow, manufacturers are increasingly adopting sustainable practices. This includes using eco-friendly materials and reducing energy consumption during production.

B. Recycling and Waste Management

Efforts are being made to recycle aluminum and other materials used in resistor manufacturing. Proper waste management practices help minimize the environmental impact of production.

C. Compliance with Environmental Regulations

Manufacturers must comply with local and international environmental regulations, ensuring that their processes do not harm the environment.

VII. Future Trends in Aluminum Shell Resistor Manufacturing

A. Innovations in Materials and Technology

The future of aluminum shell resistor manufacturing is likely to see innovations in materials, such as the development of new alloys that enhance performance and reduce weight.

B. The Impact of Industry 4.0

The rise of Industry 4.0, characterized by smart manufacturing and the Internet of Things (IoT), will further transform the production landscape. Real-time data analytics and machine learning will optimize manufacturing processes and improve quality control.

C. Predictions for the Future of Resistor Manufacturing

As technology advances, we can expect to see more efficient production methods, enhanced performance characteristics, and a greater emphasis on sustainability in aluminum shell resistor manufacturing.

VIII. Conclusion

In summary, the manufacturing processes of aluminum shell resistors involve a complex interplay of material selection, fabrication techniques, and quality control measures. These resistors play a significant role in modern electronics, offering advantages such as superior thermal management and durability. As the industry continues to evolve, advancements in manufacturing techniques and materials will further enhance the performance and sustainability of aluminum shell resistors, ensuring their relevance in the ever-changing landscape of electronics.

IX. References

- Academic journals on materials science and electronics.

- Industry reports on resistor manufacturing trends.

- Manufacturer specifications and guidelines for aluminum shell resistors.

This comprehensive overview highlights the intricate processes involved in the production of aluminum shell resistors, emphasizing their importance in the electronics industry and the innovations shaping their future.