Market Policies for High-Power Resistors

I. Introduction

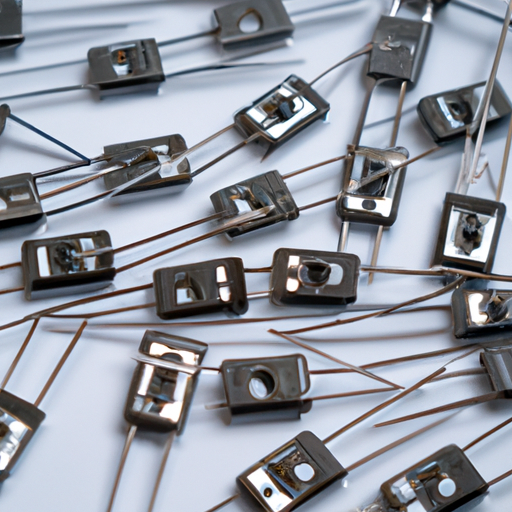

High-power resistors are essential components in various electronic and electrical applications, designed to handle significant amounts of power while maintaining stability and reliability. These resistors are crucial in industries such as automotive, telecommunications, renewable energy, and industrial automation, where they play a vital role in managing electrical energy and ensuring the proper functioning of circuits. As the demand for high-power resistors continues to grow, understanding the market policies that govern their production, distribution, and pricing becomes increasingly important. This blog post will explore the market policies affecting high-power resistors, providing insights into the regulatory framework, pricing strategies, distribution channels, and the challenges and opportunities within the market.

II. Market Overview

A. Global Demand for High-Power Resistors

The global demand for high-power resistors has been on the rise, driven by advancements in technology and the increasing need for efficient energy management. Key industries utilizing high-power resistors include:

1. **Automotive**: With the rise of electric vehicles (EVs), high-power resistors are essential for managing battery systems and regenerative braking.

2. **Telecommunications**: High-power resistors are used in base stations and other communication equipment to ensure signal integrity and reliability.

3. **Renewable Energy**: In solar and wind energy systems, high-power resistors help manage energy flow and protect against overloads.

4. **Industrial Automation**: High-power resistors are critical in various automation systems, including motor drives and power supplies.

B. Major Players in the High-Power Resistor Market

The high-power resistor market is characterized by several leading manufacturers, each vying for market share. Key players include:

1. **Vishay Intertechnology**: A prominent manufacturer known for its wide range of resistors, including high-power options.

2. **Ohmite Manufacturing Company**: Specializes in high-power resistors and has a strong presence in the industrial sector.

3. **TE Connectivity**: Offers a variety of high-power resistors for automotive and telecommunications applications.

Market share analysis indicates that these companies, along with others, are continuously innovating to meet the evolving demands of their customers.

III. Regulatory Framework

A. Overview of Regulations Affecting High-Power Resistors

The production and use of high-power resistors are subject to various regulations aimed at ensuring safety and environmental protection. Key regulations include:

1. **Safety Standards**: Organizations such as Underwriters Laboratories (UL) and the International Electrotechnical Commission (IEC) set safety standards that manufacturers must adhere to, ensuring that products can withstand high power levels without failure.

2. **Environmental Regulations**: Compliance with regulations such as the Restriction of Hazardous Substances (RoHS) directive is crucial for manufacturers to minimize the environmental impact of their products.

B. Compliance Requirements for Manufacturers

Manufacturers of high-power resistors must navigate a complex landscape of compliance requirements, including:

1. **Certification Processes**: Obtaining necessary certifications from regulatory bodies is essential for market entry and consumer trust.

2. **Testing and Quality Assurance**: Rigorous testing protocols must be followed to ensure that products meet safety and performance standards.

IV. Pricing Policies

A. Factors Influencing Pricing of High-Power Resistors

Several factors influence the pricing of high-power resistors, including:

1. **Material Costs**: The cost of raw materials, such as resistive elements and insulating materials, directly impacts pricing.

2. **Manufacturing Processes**: Advanced manufacturing techniques can increase production costs, which may be reflected in the final price.

B. Pricing Strategies Employed by Manufacturers

Manufacturers employ various pricing strategies to remain competitive in the market:

1. **Cost-Plus Pricing**: This strategy involves calculating the total cost of production and adding a markup to ensure profitability.

2. **Competitive Pricing**: Manufacturers may adjust their prices based on competitors' pricing to attract customers.

C. Impact of Tariffs and Trade Policies on Pricing

Tariffs and trade policies can significantly affect the pricing of high-power resistors, especially for manufacturers that rely on imported materials or components. Changes in trade agreements or tariffs can lead to increased costs, which may be passed on to consumers.

V. Distribution and Supply Chain Policies

A. Distribution Channels for High-Power Resistors

The distribution of high-power resistors involves various channels, including:

1. **Direct Sales vs. Distributors**: Manufacturers may choose to sell directly to customers or work with distributors to reach a broader audience.

2. **Online vs. Offline Sales**: The rise of e-commerce has led to an increase in online sales, allowing manufacturers to reach customers more efficiently.

B. Supply Chain Management Practices

Effective supply chain management is crucial for manufacturers of high-power resistors:

1. **Sourcing Raw Materials**: Establishing reliable sources for raw materials is essential to maintain production schedules and meet customer demand.

2. **Inventory Management**: Efficient inventory management practices help manufacturers minimize costs and ensure timely delivery of products.

C. Impact of Global Supply Chain Disruptions

Recent global events, such as the COVID-19 pandemic, have highlighted the vulnerabilities in supply chains. Disruptions can lead to delays in production and increased costs, prompting manufacturers to reevaluate their supply chain strategies.

VI. Marketing Strategies

A. Target Markets for High-Power Resistors

Identifying target markets is crucial for effective marketing strategies. Key markets for high-power resistors include:

1. **Industrial Applications**: High-power resistors are widely used in industrial automation and control systems.

2. **Consumer Electronics**: As electronic devices become more powerful, the demand for high-power resistors in consumer electronics is also increasing.

B. Promotional Strategies

Manufacturers employ various promotional strategies to raise awareness and drive sales:

1. **Trade Shows and Exhibitions**: Participating in industry events allows manufacturers to showcase their products and connect with potential customers.

2. **Digital Marketing and Online Presence**: A strong online presence through websites and social media platforms is essential for reaching a broader audience.

C. Customer Relationship Management

Building strong relationships with customers is vital for long-term success. Manufacturers often invest in customer relationship management (CRM) systems to track interactions and improve customer satisfaction.

VII. Innovation and Technology Policies

A. Role of Research and Development in the High-Power Resistor Market

Research and development (R&D) play a critical role in the high-power resistor market, driving innovation and product improvement. Manufacturers invest in R&D to develop new materials and technologies that enhance performance and reliability.

B. Emerging Technologies and Their Impact on Product Development

Emerging technologies, such as advanced materials and manufacturing techniques, are reshaping the high-power resistor market. These innovations enable manufacturers to create more efficient and compact products, meeting the demands of modern applications.

C. Intellectual Property Considerations

As innovation accelerates, protecting intellectual property becomes increasingly important. Manufacturers must navigate patent laws and ensure that their innovations are safeguarded against infringement.

VIII. Challenges and Opportunities

A. Challenges Facing the High-Power Resistor Market

The high-power resistor market faces several challenges, including:

1. **Competition and Market Saturation**: The increasing number of manufacturers has led to heightened competition, making it essential for companies to differentiate their products.

2. **Technological Advancements**: Rapid technological changes require manufacturers to continuously innovate to stay relevant.

B. Opportunities for Growth

Despite the challenges, there are significant opportunities for growth in the high-power resistor market:

1. **Emerging Markets**: Expanding into emerging markets presents opportunities for manufacturers to tap into new customer bases.

2. **Sustainable Practices and Eco-Friendly Products**: As consumers become more environmentally conscious, manufacturers that prioritize sustainability can gain a competitive edge.

IX. Conclusion

In summary, the market policies for high-power resistors are shaped by a complex interplay of regulatory frameworks, pricing strategies, distribution channels, and marketing efforts. As the demand for high-power resistors continues to grow across various industries, manufacturers must adapt to changing market conditions and consumer preferences. The future outlook for the high-power resistor market appears promising, with opportunities for innovation and growth in emerging markets. By staying informed about market policies and trends, manufacturers can position themselves for success in this dynamic industry.

X. References

1. Academic journals on electrical engineering and materials science.

2. Industry reports from market research firms.

3. Publications from regulatory agencies regarding safety and environmental standards.

This blog post provides a comprehensive overview of the market policies affecting high-power resistors, highlighting the importance of understanding these dynamics for manufacturers and stakeholders in the industry.