Market Policies for DC Resistors: An In-Depth Analysis

I. Introduction

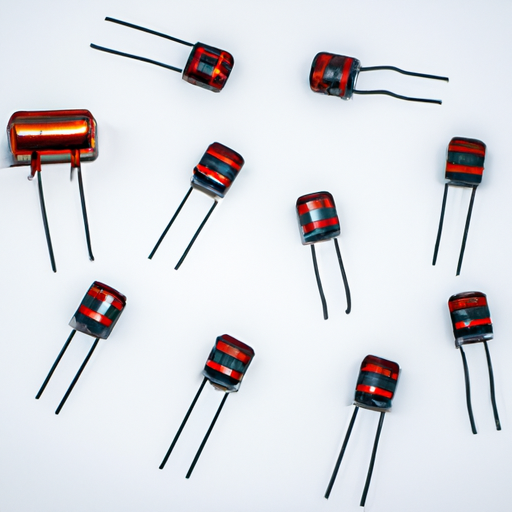

A. Definition of DC Resistors

DC resistors are passive electronic components that resist the flow of direct current (DC) in a circuit. They are fundamental in controlling voltage and current levels, ensuring that electronic devices operate safely and efficiently. Resistors come in various forms, including fixed, variable, and specialty types, each serving specific functions in electronic applications.

B. Importance of DC Resistors in Electronic Circuits

In electronic circuits, DC resistors play a crucial role in managing electrical signals. They help in voltage division, current limiting, and signal conditioning, making them indispensable in devices ranging from simple household appliances to complex industrial machinery. Their reliability and performance directly impact the overall functionality and longevity of electronic systems.

C. Overview of Market Policies

Market policies for DC resistors encompass a range of regulations, trade agreements, pricing strategies, and quality standards that govern their production, distribution, and consumption. Understanding these policies is essential for manufacturers, consumers, and stakeholders in the electronics industry to navigate the complexities of the market effectively.

II. Understanding Market Policies

A. Definition of Market Policies

Market policies refer to the guidelines and regulations established by governments and industry bodies that influence how products are manufactured, marketed, and sold. These policies aim to create a fair and competitive marketplace while ensuring consumer protection and product quality.

B. Types of Market Policies

1. **Regulatory Policies**: These are laws and regulations that govern the production and sale of DC resistors, ensuring safety and compliance with industry standards.

2. **Trade Policies**: These policies dictate how goods are imported and exported, affecting market access and competition.

3. **Pricing Policies**: These involve strategies that manufacturers use to set prices for their products, influenced by costs, competition, and market demand.

4. **Quality Standards**: These are benchmarks that products must meet to ensure reliability and safety, impacting consumer trust and market growth.

C. Importance of Market Policies in the Electronics Industry

Market policies are vital in the electronics industry as they help maintain a level playing field for manufacturers, protect consumers from substandard products, and promote innovation. They also facilitate international trade, allowing companies to expand their reach and access new markets.

III. Regulatory Policies Affecting DC Resistors

A. Government Regulations

1. **Safety Standards**: Governments impose safety regulations to ensure that DC resistors do not pose hazards to users. Compliance with these standards is mandatory for manufacturers to sell their products in various markets.

2. **Environmental Regulations**: With growing concerns about environmental sustainability, regulations are in place to limit the use of hazardous materials in electronic components, including DC resistors. Manufacturers must adhere to these regulations to minimize their environmental impact.

B. Compliance with International Standards

1. **ISO Standards**: The International Organization for Standardization (ISO) sets global standards for quality management and product safety. Compliance with ISO standards is crucial for manufacturers seeking to enhance their credibility and marketability.

2. **IEC Standards**: The International Electrotechnical Commission (IEC) provides standards specifically for electrical and electronic devices. Adhering to IEC standards ensures that DC resistors meet international safety and performance criteria.

C. Impact of Regulatory Policies on Manufacturers and Consumers

Regulatory policies significantly impact manufacturers by dictating production processes, increasing compliance costs, and influencing product design. For consumers, these regulations provide assurance of product safety and quality, fostering trust in the market.

IV. Trade Policies and Their Impact

A. Import and Export Regulations

1. **Tariffs and Duties**: Trade policies often include tariffs and duties on imported goods, affecting the pricing and availability of DC resistors in different markets. High tariffs can lead to increased costs for consumers and reduced competitiveness for manufacturers.

2. **Trade Agreements**: Bilateral and multilateral trade agreements can facilitate smoother trade flows, reducing barriers for manufacturers and enabling them to access new markets more easily.

B. Market Access and Competition

Trade policies play a crucial role in determining market access for manufacturers. Favorable trade agreements can enhance competition by allowing more players to enter the market, leading to better prices and innovation.

C. Impact of Trade Policies on Pricing and Availability

Trade policies directly influence the pricing of DC resistors. Tariffs can increase costs, while trade agreements can lower them, affecting the overall availability of products in the market. Manufacturers must navigate these policies to remain competitive.

V. Pricing Policies in the DC Resistor Market

A. Factors Influencing Pricing

1. **Material Costs**: The cost of raw materials used in manufacturing DC resistors significantly impacts pricing. Fluctuations in material prices can lead to changes in the final product cost.

2. **Manufacturing Processes**: The complexity and efficiency of manufacturing processes also affect pricing. Advanced manufacturing techniques may reduce costs but require significant initial investment.

3. **Supply and Demand Dynamics**: Market demand for DC resistors can fluctuate based on technological advancements and industry trends, influencing pricing strategies.

B. Pricing Strategies

1. **Cost-Plus Pricing**: This strategy involves adding a markup to the cost of production to determine the selling price. It ensures that manufacturers cover their costs while making a profit.

2. **Competitive Pricing**: Manufacturers may set prices based on competitors' pricing to remain competitive in the market. This strategy requires constant market analysis.

3. **Value-Based Pricing**: This approach focuses on the perceived value of the product to consumers, allowing manufacturers to charge higher prices for high-quality or innovative products.

C. Impact of Pricing Policies on Market Dynamics

Pricing policies significantly influence market dynamics, affecting competition, consumer behavior, and overall market growth. Manufacturers must adopt effective pricing strategies to navigate these dynamics successfully.

VI. Quality Standards and Their Role

A. Importance of Quality in DC Resistors

Quality is paramount in the production of DC resistors, as it directly affects performance, reliability, and safety. High-quality resistors ensure that electronic devices function optimally and reduce the risk of failures.

B. Quality Assurance Processes

Manufacturers implement quality assurance processes to monitor and maintain product quality throughout the production cycle. These processes include rigorous testing and inspection to ensure compliance with established standards.

C. Certification and Testing

Certification from recognized bodies enhances consumer trust and marketability. Manufacturers often seek certifications to demonstrate compliance with quality standards, which can be a significant selling point.

D. Impact of Quality Standards on Consumer Trust and Market Growth

Adhering to quality standards fosters consumer trust, leading to increased sales and market growth. Consumers are more likely to choose products from manufacturers known for their commitment to quality.

VII. Market Trends and Future Outlook

A. Technological Advancements

The DC resistor market is witnessing rapid technological advancements, leading to the development of more efficient and reliable products. Manufacturers must stay abreast of these trends to remain competitive.

B. Sustainability and Eco-Friendly Practices

With growing environmental concerns, there is an increasing demand for sustainable and eco-friendly practices in the production of DC resistors. Manufacturers are exploring ways to reduce waste and use environmentally friendly materials.

C. Emerging Markets and Global Demand

Emerging markets present significant opportunities for growth in the DC resistor market. As technology adoption increases in these regions, the demand for electronic components, including resistors, is expected to rise.

D. Predictions for Future Market Policies

Future market policies are likely to focus on sustainability, innovation, and consumer protection. Manufacturers must adapt to these evolving policies to thrive in the competitive landscape.

VIII. Conclusion

A. Summary of Key Points

Market policies for DC resistors encompass a wide range of regulations, trade agreements, pricing strategies, and quality standards that shape the industry. Understanding these policies is essential for manufacturers and consumers alike.

B. The Importance of Adapting to Market Policies

As the electronics industry continues to evolve, adapting to market policies will be crucial for manufacturers to remain competitive and meet consumer demands.

C. Final Thoughts on the Future of DC Resistor Market Policies

The future of market policies for DC resistors will likely be influenced by technological advancements, sustainability initiatives, and changing consumer preferences. By staying informed and adaptable, stakeholders in the DC resistor market can navigate these changes and seize new opportunities for growth.