What is the Price of Popular Wirewound Resistor Models in Stock?

I. Introduction

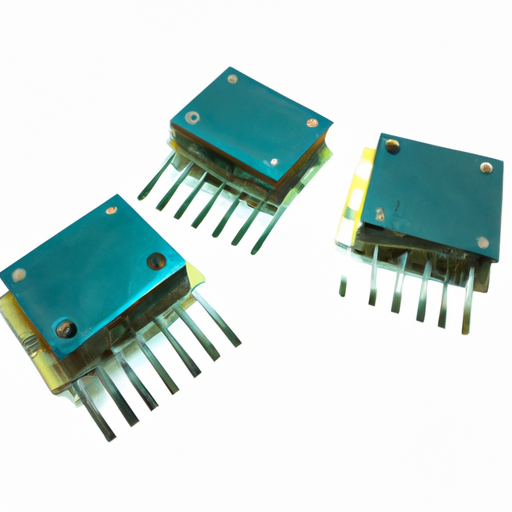

Wirewound resistors are a fundamental component in the world of electronics, known for their reliability and precision. These resistors are constructed by winding a wire around a core, typically made of ceramic or another insulating material, which allows them to handle higher power ratings and provide better thermal stability compared to other resistor types. Their importance in various electronic applications, from power supplies to audio equipment, cannot be overstated. This article aims to explore the pricing of popular wirewound resistor models currently in stock, providing insights into what factors influence their costs and where to find them.

II. Understanding Wirewound Resistors

A. Construction and Materials

Wirewound resistors are made from a variety of materials that contribute to their performance. The wire itself is often composed of alloys such as nickel-chromium or copper-nickel, which offer excellent conductivity and resistance to oxidation. The insulating materials used in the construction can vary, with ceramic being a common choice due to its high thermal resistance and durability.

B. Types of Wirewound Resistors

Wirewound resistors can be categorized into two main types:

1. **Fixed Wirewound Resistors**: These resistors have a predetermined resistance value and are widely used in applications where a stable resistance is required.

2. **Variable Wirewound Resistors (Potentiometers)**: These allow for adjustable resistance, making them ideal for applications such as volume controls in audio equipment.

C. Key Characteristics

When selecting wirewound resistors, several key characteristics should be considered:

1. **Resistance Range**: Wirewound resistors are available in a wide range of resistance values, typically from a few ohms to several megohms.

2. **Power Rating**: This indicates the maximum power the resistor can dissipate without overheating, usually measured in watts.

3. **Tolerance Levels**: This refers to the precision of the resistor's value, with common tolerances ranging from 1% to 5%.

4. **Temperature Coefficient**: This measures how much the resistance changes with temperature, which is crucial for applications requiring stability across varying temperatures.

III. Factors Influencing the Price of Wirewound Resistors

Several factors contribute to the pricing of wirewound resistors:

A. Material Costs

The cost of raw materials, such as the wire alloys and insulating materials, directly impacts the price of wirewound resistors. Fluctuations in the market for these materials can lead to price changes.

B. Manufacturing Processes

The complexity of the manufacturing process also plays a role. High-precision manufacturing techniques and quality control measures can increase production costs, which are then reflected in the retail price.

C. Brand Reputation

Established brands with a reputation for quality and reliability often command higher prices. Customers may be willing to pay a premium for products from trusted manufacturers.

D. Supply and Demand Dynamics

Market demand for specific resistor models can influence pricing. If a particular model is in high demand but low supply, prices may rise accordingly.

E. Technological Advancements

Innovations in resistor technology, such as improved materials or manufacturing techniques, can lead to better performance and potentially higher prices.

IV. Popular Wirewound Resistor Models

A. Overview of Leading Manufacturers

Several manufacturers are well-known for producing high-quality wirewound resistors:

1. **Vishay**: A leading manufacturer known for a wide range of electronic components, including wirewound resistors.

2. **Ohmite**: Specializes in resistive products and is recognized for its durable and reliable wirewound resistors.

3. **Bourns**: Offers a variety of electronic components, including precision wirewound resistors.

4. **TE Connectivity**: Known for its connectivity and sensor solutions, TE also produces high-quality wirewound resistors.

B. Description of Popular Models

1. **Vishay W22 Series**: This series is known for its high power ratings and excellent thermal stability, making it suitable for demanding applications.

2. **Ohmite 50 Series**: These resistors are designed for high-performance applications, offering a wide resistance range and low temperature coefficients.

3. **Bourns 3300 Series**: This series features precision wirewound resistors with low tolerances, ideal for applications requiring high accuracy.

4. **TE Connectivity 1N Series**: Known for their reliability and robustness, these resistors are suitable for a variety of industrial applications.

V. Pricing Analysis of Popular Models

A. Price Ranges for Each Model

The prices of wirewound resistors can vary significantly based on the model and specifications. Here’s a general overview of the price ranges for popular models:

1. **Vishay W22 Series**: Prices typically range from $0.50 to $5.00 per unit, depending on the resistance value and power rating.

2. **Ohmite 50 Series**: These resistors are generally priced between $1.00 and $10.00, with higher prices for models with greater power ratings.

3. **Bourns 3300 Series**: Expect to pay around $1.50 to $8.00 per unit, depending on the precision and resistance value.

4. **TE Connectivity 1N Series**: Prices for this series usually range from $0.75 to $6.00, influenced by the specific application requirements.

B. Comparison of Prices Across Different Suppliers

When shopping for wirewound resistors, it’s essential to compare prices across various suppliers. Online retailers like Digi-Key, Mouser Electronics, and Newark often have competitive pricing, but it’s advisable to check for bulk purchase discounts or seasonal sales that can further reduce costs.

C. Seasonal Trends and Discounts

Pricing for electronic components, including wirewound resistors, can fluctuate based on seasonal trends. For instance, during back-to-school sales or holiday promotions, suppliers may offer discounts that can significantly lower the cost of these components.

VI. Where to Buy Wirewound Resistors

A. Online Retailers

1. **Digi-Key**: A leading distributor of electronic components, Digi-Key offers a vast selection of wirewound resistors from various manufacturers.

2. **Mouser Electronics**: Known for its extensive inventory, Mouser provides detailed specifications and competitive pricing for wirewound resistors.

3. **Newark**: This supplier offers a wide range of electronic components, including wirewound resistors, with options for bulk purchasing.

B. Local Electronic Component Stores

For those who prefer to shop in person, local electronic component stores can be a valuable resource. These stores often carry a selection of wirewound resistors and can provide expert advice on suitable models for specific applications.

C. Wholesale Distributors

Wholesale distributors can be an excellent option for businesses or individuals looking to purchase wirewound resistors in bulk. These distributors often offer lower prices per unit, making them a cost-effective choice for larger projects.

VII. Conclusion

In summary, wirewound resistors are essential components in many electronic applications, and understanding their pricing is crucial for making informed purchasing decisions. Factors such as material costs, manufacturing processes, and brand reputation all play a role in determining the price of these resistors. By exploring popular models from leading manufacturers and comparing prices across various suppliers, consumers can find the best options for their needs. As technology continues to advance, the future outlook for wirewound resistors remains promising, with potential for improved performance and pricing trends.

VIII. References

- Manufacturer websites for pricing data

- Online electronic component retailers

- Industry publications on wirewound resistors and their applications

By understanding the intricacies of wirewound resistors and their pricing, you can make better choices for your electronic projects, ensuring reliability and performance in your applications.