What is the Current Status of the Braking Resistor Industry?

I. Introduction

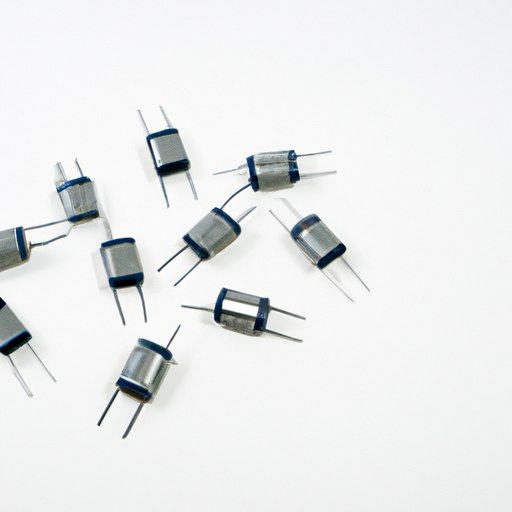

Braking resistors are essential components in various electrical systems, designed to dissipate excess energy generated during braking processes. They play a crucial role in ensuring the safe and efficient operation of electric motors, particularly in applications where rapid deceleration is required. As industries increasingly adopt electric and hybrid technologies, the importance of braking resistors has grown significantly. This blog post explores the current status of the braking resistor industry, examining market trends, technological advancements, applications, challenges, and future outlook.

II. Market Overview

A. Global Market Size and Growth Trends

The braking resistor market has experienced notable growth over the past decade. Historically, the industry has seen a steady increase in demand, driven by the rise of electric vehicles (EVs), automation in industrial processes, and the expansion of renewable energy systems. As of 2023, the global market valuation for braking resistors is estimated to be in the range of several hundred million dollars, with projections indicating continued growth in the coming years.

1. **Historical Growth Patterns**: The market has evolved from traditional applications in industrial machinery to more advanced uses in modern technologies. The shift towards electrification and automation has been a significant driver of this growth.

2. **Current Market Valuation**: Recent estimates suggest that the braking resistor market is valued at approximately $XXX million, with a compound annual growth rate (CAGR) of around X% over the last five years.

3. **Future Projections**: Analysts predict that the market will continue to expand, potentially reaching $XXX million by 2030, fueled by advancements in technology and increasing adoption of electric vehicles and renewable energy solutions.

B. Key Players in the Industry

The braking resistor industry is characterized by a mix of established manufacturers and emerging companies.

1. **Major Manufacturers**: Key players include companies like ABB, Siemens, and Schneider Electric, which have a strong presence in the industrial sector and are known for their high-quality braking resistors.

2. **Emerging Companies**: New entrants are also making their mark, particularly in niche markets and innovative technologies. Startups focusing on smart braking solutions and IoT integration are gaining traction.

C. Regional Analysis

The braking resistor market is geographically diverse, with significant activity in various regions.

1. **North America**: The North American market is driven by the automotive sector, particularly the growth of electric and hybrid vehicles. The region is also home to several leading manufacturers.

2. **Europe**: Europe is a key player in the braking resistor market, with stringent regulations promoting energy efficiency and sustainability. The region's focus on renewable energy and electric mobility is further propelling market growth.

3. **Asia-Pacific**: The Asia-Pacific region is witnessing rapid industrialization and urbanization, leading to increased demand for braking resistors in manufacturing and transportation sectors.

4. **Rest of the World**: Emerging markets in Latin America and Africa are beginning to adopt electric technologies, presenting new opportunities for the braking resistor industry.

III. Technological Advancements

A. Innovations in Braking Resistor Design

The braking resistor industry is undergoing significant technological advancements, with innovations aimed at improving performance and efficiency.

1. **Materials Used**: Manufacturers are exploring new materials that enhance thermal management and durability. Advanced alloys and composites are being utilized to create more efficient braking resistors.

2. **Efficiency Improvements**: Innovations in design have led to braking resistors that can handle higher power loads while minimizing energy loss. This is particularly important in applications where energy efficiency is critical.

B. Integration with Modern Technologies

Braking resistors are increasingly being integrated with modern technologies, enhancing their functionality and application scope.

1. **Electric Vehicles (EVs)**: The rise of electric vehicles has created a demand for advanced braking systems that can efficiently manage regenerative braking. Braking resistors play a vital role in dissipating excess energy during this process.

2. **Renewable Energy Systems**: In renewable energy applications, such as wind turbines and solar inverters, braking resistors are essential for managing energy flow and ensuring system stability.

C. Smart Braking Resistors and IoT Integration

The advent of the Internet of Things (IoT) has opened new avenues for braking resistor technology. Smart braking resistors equipped with sensors can provide real-time data on performance, enabling predictive maintenance and improved operational efficiency.

IV. Applications of Braking Resistors

Braking resistors find applications across various sectors, each with unique requirements and challenges.

A. Industrial Applications

1. **Cranes and Hoists**: In industrial settings, braking resistors are crucial for cranes and hoists, where precise control and rapid deceleration are necessary for safety and efficiency.

2. **Elevators and Escalators**: Braking resistors ensure smooth operation in elevators and escalators, providing reliable braking performance and energy management.

B. Transportation

1. **Electric and Hybrid Vehicles**: The automotive industry is a significant consumer of braking resistors, particularly in electric and hybrid vehicles that rely on regenerative braking systems.

2. **Rail Systems**: Braking resistors are also used in rail systems, where they help manage energy during braking and improve overall system efficiency.

C. Renewable Energy

1. **Wind Turbines**: In wind energy applications, braking resistors are essential for controlling the speed of turbines and preventing overspeed conditions.

2. **Solar Inverters**: Braking resistors play a role in solar inverters, helping to manage energy flow and ensure system stability during fluctuations in solar power generation.

V. Challenges Facing the Industry

Despite the positive outlook, the braking resistor industry faces several challenges that could impact its growth.

A. Supply Chain Disruptions

Recent global events have highlighted vulnerabilities in supply chains, affecting the availability of raw materials and components necessary for manufacturing braking resistors.

B. Regulatory and Compliance Issues

As industries move towards more sustainable practices, compliance with environmental regulations is becoming increasingly important. Manufacturers must adapt to changing regulations to remain competitive.

C. Competition from Alternative Technologies

The emergence of alternative technologies, such as advanced energy storage systems, poses a challenge to the traditional braking resistor market. Companies must innovate to differentiate their products.

D. Environmental Concerns and Sustainability

The industry is under pressure to adopt more sustainable practices, including the use of eco-friendly materials and energy-efficient manufacturing processes.

VI. Future Outlook

A. Predictions for Market Growth

The braking resistor market is expected to continue its upward trajectory, driven by the increasing adoption of electric vehicles, automation in industries, and the growth of renewable energy systems.

B. Potential Technological Breakthroughs

Future advancements in materials science and engineering could lead to the development of even more efficient braking resistors, enhancing their performance and expanding their applications.

C. Shifts in Consumer Demand and Preferences

As consumers become more environmentally conscious, there will be a growing demand for energy-efficient solutions, prompting manufacturers to innovate and adapt their offerings.

D. The Role of Government Policies and Incentives

Government policies promoting electric mobility and renewable energy will play a crucial role in shaping the future of the braking resistor industry, providing incentives for manufacturers to invest in research and development.

VII. Conclusion

In summary, the braking resistor industry is at a pivotal point, characterized by significant growth, technological advancements, and evolving applications. As industries adapt to changing technologies and consumer preferences, the importance of braking resistors will only continue to rise. Manufacturers must remain agile, embracing innovation and sustainability to thrive in this dynamic landscape. The future of the braking resistor industry looks promising, with ample opportunities for growth and development in the years to come.

VIII. References

- Academic journals on electrical engineering and energy systems.

- Industry reports from market research firms.

- Market analysis publications focusing on the automotive and renewable energy sectors.

- Relevant websites and articles discussing technological advancements and market trends in the braking resistor industry.

This comprehensive overview provides insights into the current status of the braking resistor industry, highlighting its significance in modern applications and the challenges it faces as it moves forward.